Professional Poultry Cage Manufacturer

Hightop® poultry equipment provides quality poultry cages (also layer cages or battery cages), click the inquiry button to get the latest price and free Poultry Farm Layout Design.

The 19th Davao Agri Trade Expo 2017

We’ll participate in the 19th Davao Agri Trade Expo in Philippines, from September 21-23, 2017. booth number is S17. Welcome to visit our booth. Click Here For Details

Why use Layer Cage

A layer cage is used for rearing egg-laying chickens after the pullet has grown for 12 to 16 weeks.

The biggest advantage of layer cages is that they effectively increase egg production to 98%. They also make it very easy to handle chicken waste (especially manure) and to reduce transmission of diseases.

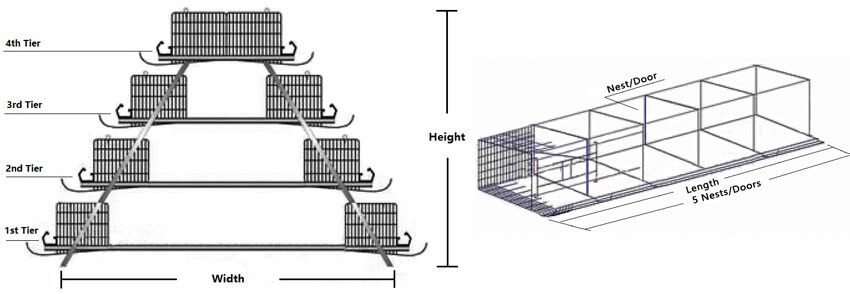

| “A” Type Chicken Cage Specifications | ||||||

| Item No. | Tier & Nest | Size (L x W x H) | Nos of Nest per Tier | Nos of Nest per Set | Nos of hens per Nest | Nos of hens per Set |

| HT-A34 (Hot Sale) | 3 Tiers, 4 Nests | 1.88 x 2.1 x 1.5m | 8 | 24 | 4 | 96 |

| HT-A34L | 3 Tiers, 4 Nests | 2.0 x 2.1 x 1.5m | 8 | 24 | 4 | 96 |

| HT-A35 (Hot Sale) | 3 Tiers, 5 Nests | 1.95 x 2.1 x 1.5m | 10 | 30 | 3 or 4 | 90 or 120 |

| HT-A35L | 3 Tiers, 5 Nests | 2.15 x 2.1 x 1.5m | 10 | 30 | 4 | 120 |

| HT-A44 | 4 Tiers, 4 Nests | 1.88 x 2.4 x 1.95m | 8 | 32 | 4 | 128 |

| HT-A45 | 4 Tiers, 5 Nests | 1.95 x 2.4 x 1.95m | 10 | 40 | 3 or 4 | 120 or 160 |

| HT-A45L | 4 Tiers, 5 Nests | 2.15 x 2.4 x 1.95m | 10 | 40 | 4 | 160 |

| HT-A55 | Not Recommended, because the cage is very high and not convenient to manage. | |||||

| 5 Tiers, 5 Nests | 1.95 x 2.8 x 2.5m | 10 | 50 | 3 or 4 | 150 or 200 | |

| Item No. Desc | “HT” – Hightop® brand; “A” – A type/shape; “34” – 3 tiers 4 nests/doors; “L” – Large size | |||||

| Material | Q195 low carbon steel wire or Q235 low carbon steel wire |

|||||

| The Finish | 1. Electro Galvanized or 2. Hot Dipped Galvanized or 3. PVC Coated. |

|||||

| Life span | Electro Galvanization (7-10 years); Hot Dip Galvanization (15-20 years); PVC Coated (15-20 years) |

|||||

How to choose the equipment you need?

- If you have less than 2,000 chickens we advise you to only buy layer cages. Drinking system is automated, but workers need to feed the chicken manually, as well as collect the eggs, and remove the droppings.

- If you have between 5,000 and 10,000 chickens we suggest you purchase a manure removal machine as well as a layer cage or cages. By removing the droppings timeously, you will reduce the possibility of disease and improve the egg production rate, at the same time saving even more time and labor costs. The scrapper scraper type manure removal machine is the most economical type. A semi-automatic feeding machine is also necessary for this quantity of chickens. It is small and costs less than a fully automatic machine, and because it uses a battery, you will avoid the inconvenience of power failures. You can feed 10,000 chicken in just half an hour, and save a lot on labor.

- If you have more than 10,000 chickens you may need to get fully automated machines including one that does automatic feeding, another for automatic egg collection, as well as an automatic manure removal machine. If the scale of your operation exceeds 50,000 chickens, you will need a feed silo. For less than 50,000 chickens you can just use one screw conveyor to convey the food to the hopper. If you want to build a closed system, you need to know that an exhaust fan and cooling pad are necessary environment control equipment items. If you use an open system and the weather is hot, you can use a fogger.

Hightop Broiler Cage

Hightop poultry equipment has been in the chicken cage manufacturing for about 15 years and has rich experience in poultry farm design, as an iso9001-2008 certificated company, our products and services have the following advantages:

- Cage lifespan can reach 7-20 years depending on the material and environment;

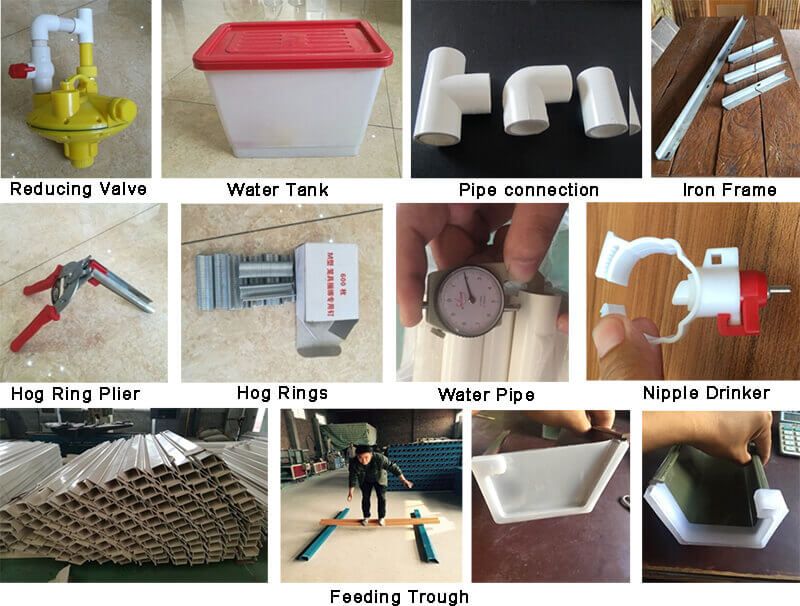

- Providing full accessories – Nipple drinking system, medication tanks, water tanks, adjustable foot plates for leveling, water pipe, pipe connector, feeding trough, cage iron frame, etc;

- Related matching equipment optional;

- On time delivery;

- Free chicken cage layout design;

- Cage installation instruction & video installation guide;

- One-stop shopping;

- Professional team help you build the scientific farm;

- Best pre-sales and after-sales service;

- Prompt reply within 12 hours.

| Broiler Cage Specifications | ||||||

| Item No. | Type | Size (L x W x H) | Nos of Nest per Tier | Nos of Nest per Set | Nos of Broiler per Nest | Nos of Broiler per Set |

| HT-BH3 | “H” Type, 3 Tiers | 1.4 x 0.7 x 1.75m | 2 | 6 | 9 or 10 | 54 or 60 |

| HT-BA3 | “A” Type, 3 Tiers | 1.95 x 2.4 x 1.5m | 6 | 18 | 4 | 72 |

| Item No. Desc | “HT” – Hightop® brand; “B”-Broiler; “H” – H type/shape; “A”-A type; “3” – 3 tiers | |||||

| Material | Q195 low carbon steel wire or | |||||

| Q235 low carbon steel wire | ||||||

| The Finish | 1. Electro Galvanized or | |||||

| 2. Hot Dipped Galvanized or | ||||||

| 3. PVC Coated. | ||||||

| Life span | Electro Galvanization (7-10 years); | |||||

| Hot Dip Galvanization (15-20 years); | ||||||

| PVC Coated (15-20 years) | ||||||

How to choose the other equipment using H type broiler cage?

- If you hatch the chicks on your farm you may need an incubator and hatcher. We can provide equipment for a 48,000 to 50,000 egg capacity.

- If you choose H type broiler cages these already have a manure cleaning system. It is best to place 40-70 sets in one line, which means that the length of the broiler house will be between 60 and 104 m. If the quantity you order is small the cages will not include the manure-cleaning belt. Instead we will use a plate to collect the droppings.

- You can also use our semi-automatic feeding machine for H type cages to feed the food. These are small and cost less than fully automatic machines and because they use a battery only, they avoid the problems associated with power failures. You can feed 10,000 broilers in about half an hour, which represents a great labor saving cost.

Day old chick cage

Chick cages are used for baby chickens, because the mesh size of adult cage is too large for these babies. The chick cage can hold the day old chicks for two to four weeks.

| Specifications of Chick Cage | ||||||

| Item No. | Type | Size (L x W x H) | Nos of Nest per Tier | Nos of Nest per Set | Nos of Chick per Nest | Nos of Chick per Set |

| HT-CH3 | “H” Type, 3 Tiers | 1.4 x 0.7 x 1.2m | 2 | 6 | 19 | 114 |

| HT-CH4 | “H” Type, 4 Tiers | 1.4 x 0.7 x 1.65m | 2 | 8 | 19 | 152 |

| HT-CA3 | “A” Type, 3 Tiers | 2.0 x 2.4 x 1.46m | 6 | 18 | 12 | 216 |

| Item No. Desc | “HT” – Hightop® brand; “C” – Chick Cage; “A”-A Type; “H”-H type/shape; “3” – 3 tiers | |||||

| Material | Q195 low carbon steel wire or | |||||

| Q235 low carbon steel wire | ||||||

| The Finish | 1. Electro Galvanized or | |||||

| 2. Hot Dipped Galvanized or | ||||||

| 3. PVC Coated. | ||||||

| Life span | Electro Galvanization (7-10 years); | |||||

| Hot Dip Galvanization (15-20 years); | ||||||

| PVC Coated (15-20 years) | ||||||

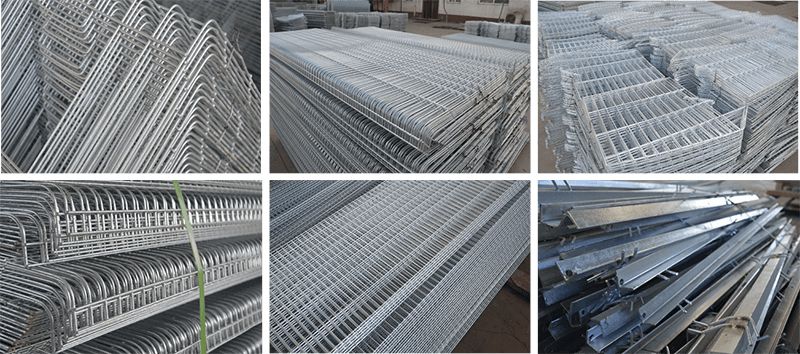

1. Raw material selection of our layer cage

The hardness of metal wire depends on its carbon content. The metal wire we use for our layer cage comes from a large steel factory in China and it is very tough and hard, as well as ductile and malleable so that it is not damaged under stress. Our layer cage generally has a lifespan that is at least three years more than the common factory-made types.

2. Lifespan of up to 20 years

The thick zinc coating on the hot-dipped galvanized cage mesh will ensure your layer cage will be protected from corrosion and rust for at least 10 years, while the layer cage itself will last for double this time.

3. Layer cage mesh design

The big sliding door design makes it easy to remove the chickens. The density of the bottom cage mesh also prevents feather and anus pecking, and minimizes layer chicken fatigue syndrome.

4. All necessary accessories are included

Accessories comprise a regulator or water tank, a water tank frame, a nipple drinker, installation tool, M-nail, water pipe, connector for the pipe, feeder connector, end cup, and the best type of PVC feeder trough.

5. Very easy to install.

We can send layer cage installation video to you. You can check it out on YouTube: https://www.youtube.com/watch?v=htrRyqfKb6s

6. Free layout design

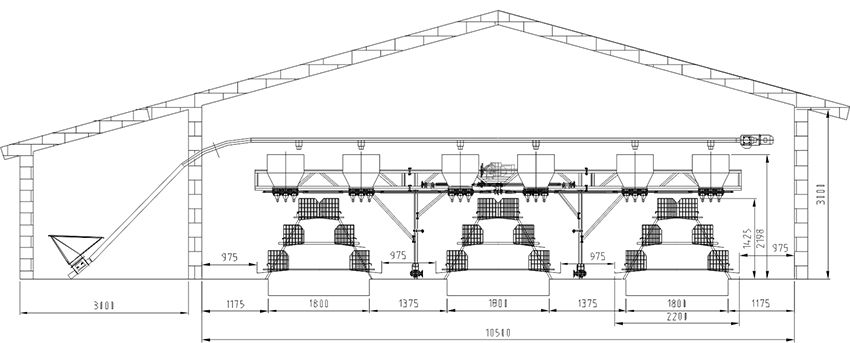

We offer a free design service based on the size of chicken house or coop you want.

- Chickens will start laying eggs when they are between 12 and 16 weeks old. So when they are this age, transfer them to the layer cage

- We can provide a free layout design according to your chicken coop size. Alternatively, we can give you suitable advice according to the quantity of chickens you want to feed if you have not already built your chicken house.

- Our semi-automatic feeding machine is 0.55m wide. The minimum width to be able to use our semi-automatic feeding machine is 0.7 m, but if your area is very hot, and the scale of the chicken house is large, the width can be bigger to ensure good ventilation. Usually we design walkways to be between 0.7 m and 1.2 m.

- If you plan to use our manure-cleaning machine, the depth of the channel should be about 50 cm.

- The 3-tier cage is 1.5m long and the 4-tier cage is 1.95m, so the height of the chicken house should be about 2.8 m to 3 m.

7. If LCL handles delivery, you will receive your goods in firm, solid packaging

8. Many customers order full containers and get back to our company after they receive the goods

We can also provide poultry house layout design