Egg grader machine also called egg sorter machine, Hightop provides different models of egg grader machine from 4000 pcs/h to 20000 pcs/h including two popular types of large scale machines.

Commercial Egg Grader Machine Working Process

The basic working process of egg sorter machines are as follows:

- Workers put the eggs onto the roller belt manually.

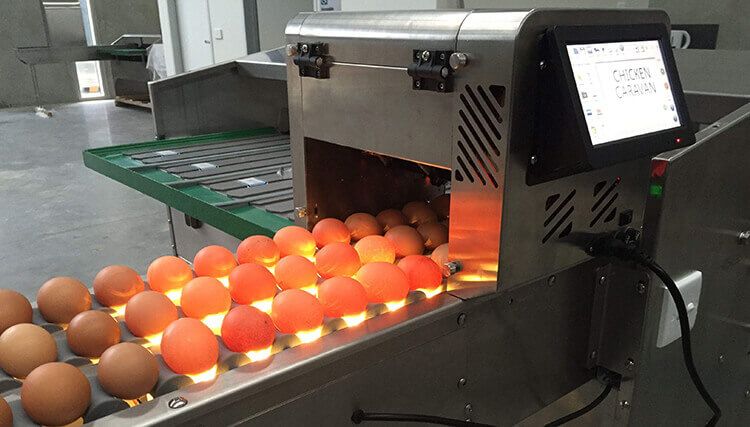

- The roller belt conveys the eggs into a candling section where a light comes on under the eggs. This light visually penetrates the eggs so workers can select and remove stale eggs, cracked eggs, black-cored eggs, and mildewed eggs.

- After this candling process the “good” eggs are conveyed into the grading section of the machine where they are divided into several grades according to weight. The way this grading process works is that eggs of different weights fall through different channels and eggs of the same weight fall down into the same channel.

- The workers collect the eggs from different channels and pack them into different egg trays manually.

Features of Egg Sorting Machine

- Constructed from high quality stainless steel for great durability and hygiene.

- Equipped with color touchscreen PLC control system and can sort eggs into maximum of 5 grades, using an electronic sensor weighing scale with accuracy ±1g.

- The manual packing table is flexible and equipped with locking casters, which makes it easier for cleaning and maintenance.

- Egg sorting can be connected with egg testing, egg washing, egg ink jet printer, egg packing device.

- It can be connected with your automatic egg conveyor

Specifications

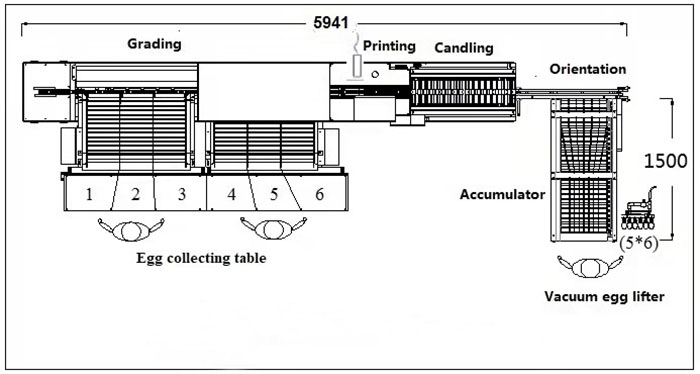

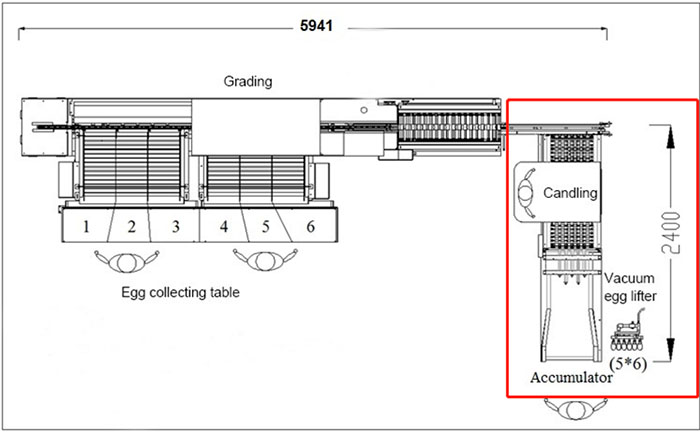

| MODE | Capacity | Accuracy | Grades | Power | Voltage | Size | Net Weight | Gross weight |

| HTP-1500 | 10,000 eggs/h | ±1g | 6 | 1.5KW

50HZ |

220V, single phase

380V, 3- phase |

5.94 x 2.4 x 2 m | 550 kg | 550 kg |

Specifications

| MODE | Capacity | Accuracy | Grades | Power | Voltage | Size | Net Weight | Gross weight |

| HTP-2400 | 10,000 eggs/h | ±1g | 5 | 1.9KW

50HZ |

220V, single phase

380V, 3- phase |

9.13×5.8×2 m | 700 kg | 1100 kg |

| Small capacity egg grading machine available | |||

| NO. | Item | Specification | |

| 1 | HT-J2 egg grading machine | Type | HTZY-J2 |

| Capacity | 4000pcs/h | ||

| Material | Carbon steel | ||

| Precision | ±0.5g | ||

| Grade | 7 | ||

| Power | 200W | ||

| Voltage | 220V | ||

| L x W x H | 1438 x 1320 x 980(mm) | ||

| Net weight | 160KG | ||

| Gross weight | 200KG | ||

| Function | Grading eggs by weight | ||

| 2 | HT-J3 egg grading machine | Model | HTZY-J3 |

| Capacity | 5400 pcs/h | ||

| Material | Carbon steel | ||

| Precision | ±0.5g | ||

| Grade | 5 | ||

| Power | 200W | ||

| Voltage | 220V | ||

| L x W x H | 1820 x 1620 x 1050(mm) | ||

| Gross Weight | 260KG | ||

| Net Weight | 190KG | ||

| Function | Grading eggs by weight | ||