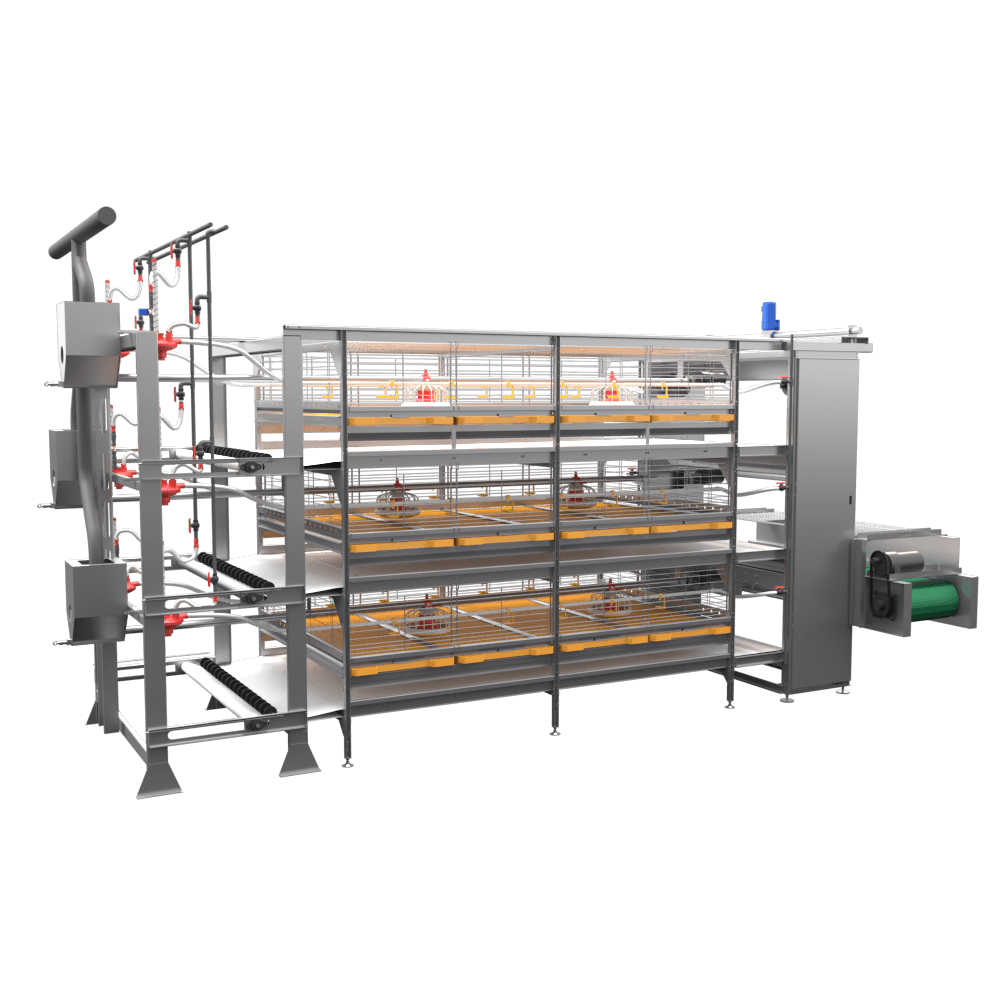

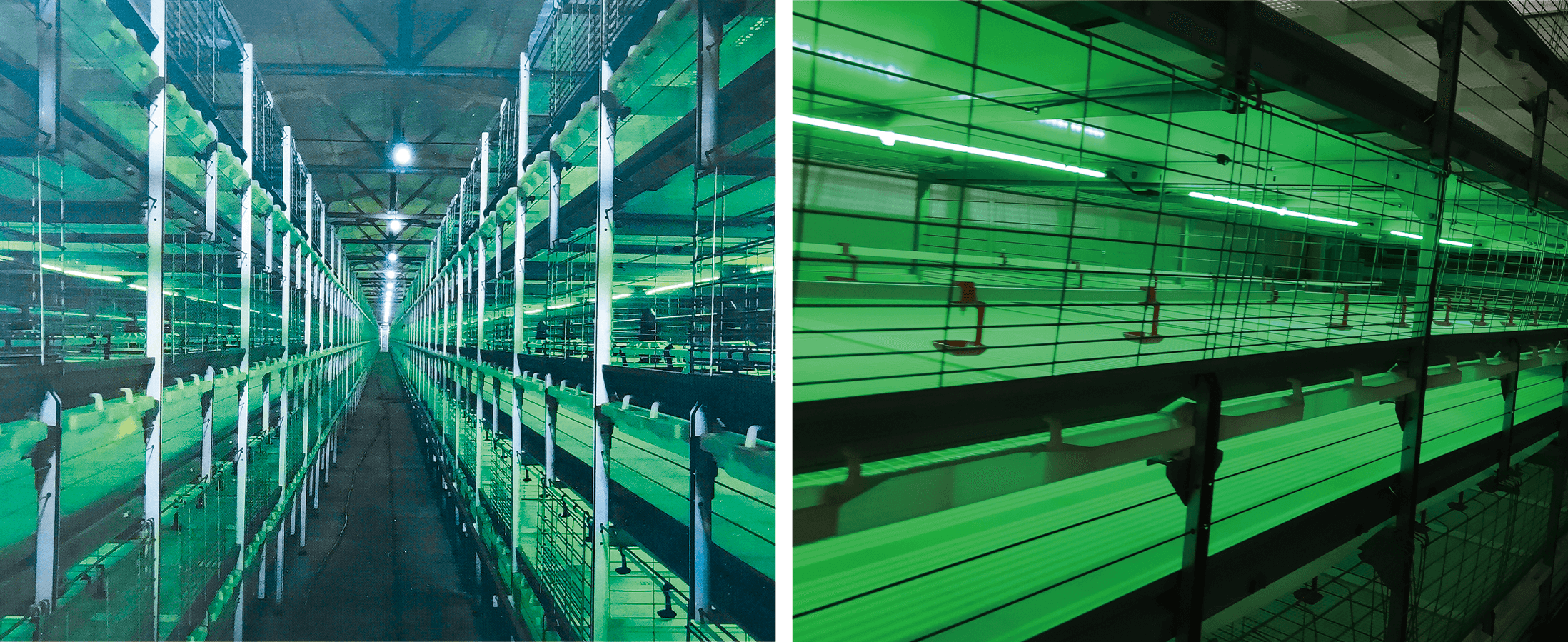

Automatic Harvesting Broiler Cage

There are two types of automatic broiler cages: the pull-out slat type and the new chain type. Both types feature automatic feeding, manure cleaning, and chicken collection functions. For the pull-out slat type, the detachable tray inside the cage is pulled out, causing the chickens to fall onto the manure belt. The manure belt then transports the chickens to the end of the cage, where the horizontal chicken collector lifts them out of the chicken house and places them on a round table for collection. Workers can gather the chickens from the round table, eliminating the need to manually collect them from each cage. This method not only reduces the injury rate of the chickens but also speeds up the collection process.

Dive into the future of poultry farming with our latest video, showcasing the marvels of Automatic Broiler Cages.

Save labor

Less harvesting labor

Save time

Bird-harvesting>6000 birds/hr

Save Feed

Feed-to-meat Ratio 1.4:1

Long Lifespan

15-20 years

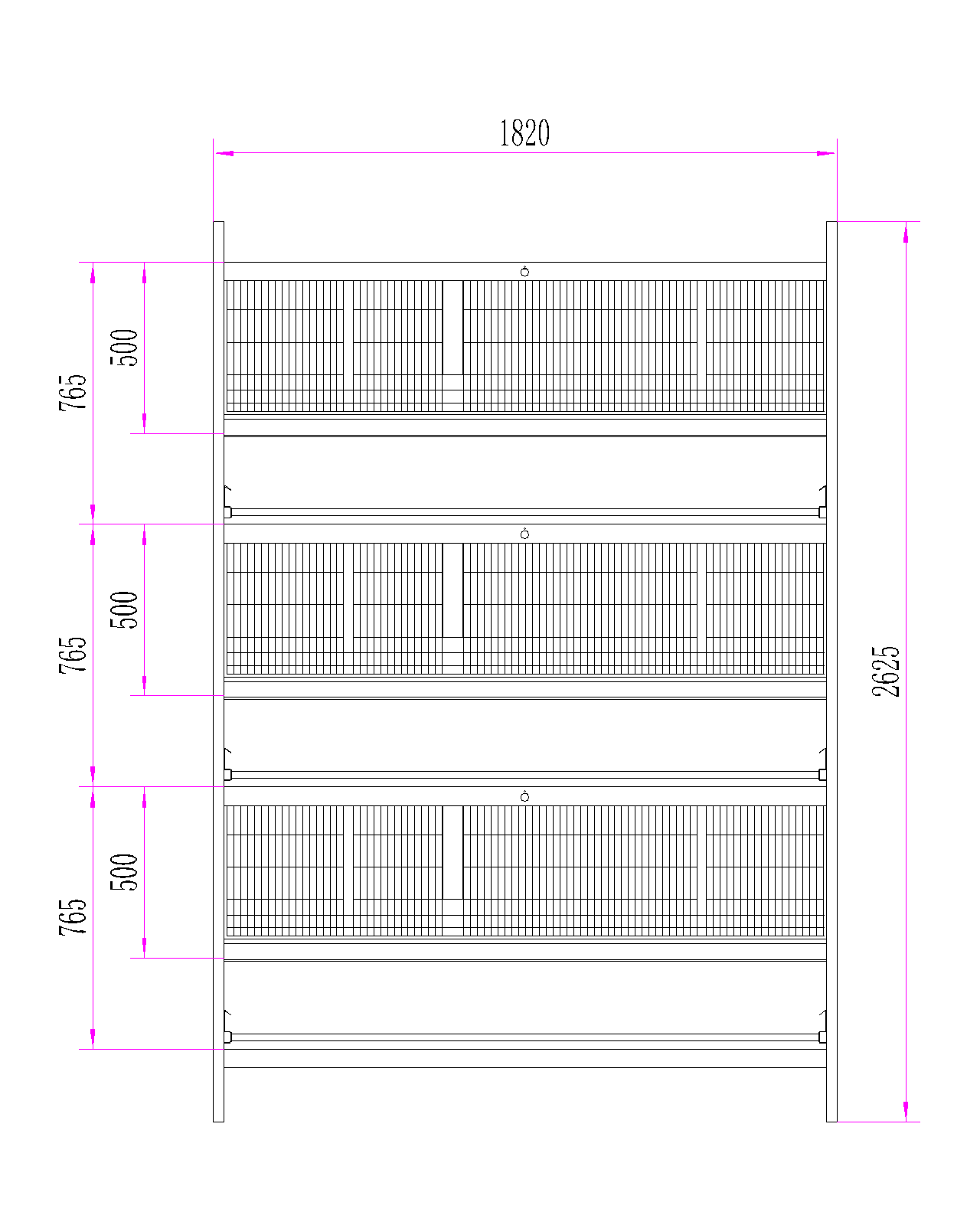

Automatic Harvesting Broiler Cage Drawing

cage size

| Building size recommend | |||||||||

| Recommend building size | Chicken Quantity | ||||||||

| 90m*17.3m*4.5m (4-tier cage) | 81000(1.8kg bird) | ||||||||

| 80m*14.5m*4.2m (3-tier cage) | 41400(1.8kg bird) | ||||||||

| Cage information | |||||||||

| Cell Size | Length 3000mm, width

1820mm, height 500mm |

||||||||

| Raising Area | 364cm² | ||||||||

| Broiler Quantity per Cell | 150 birds/cell(<1.8kg) | ||||||||

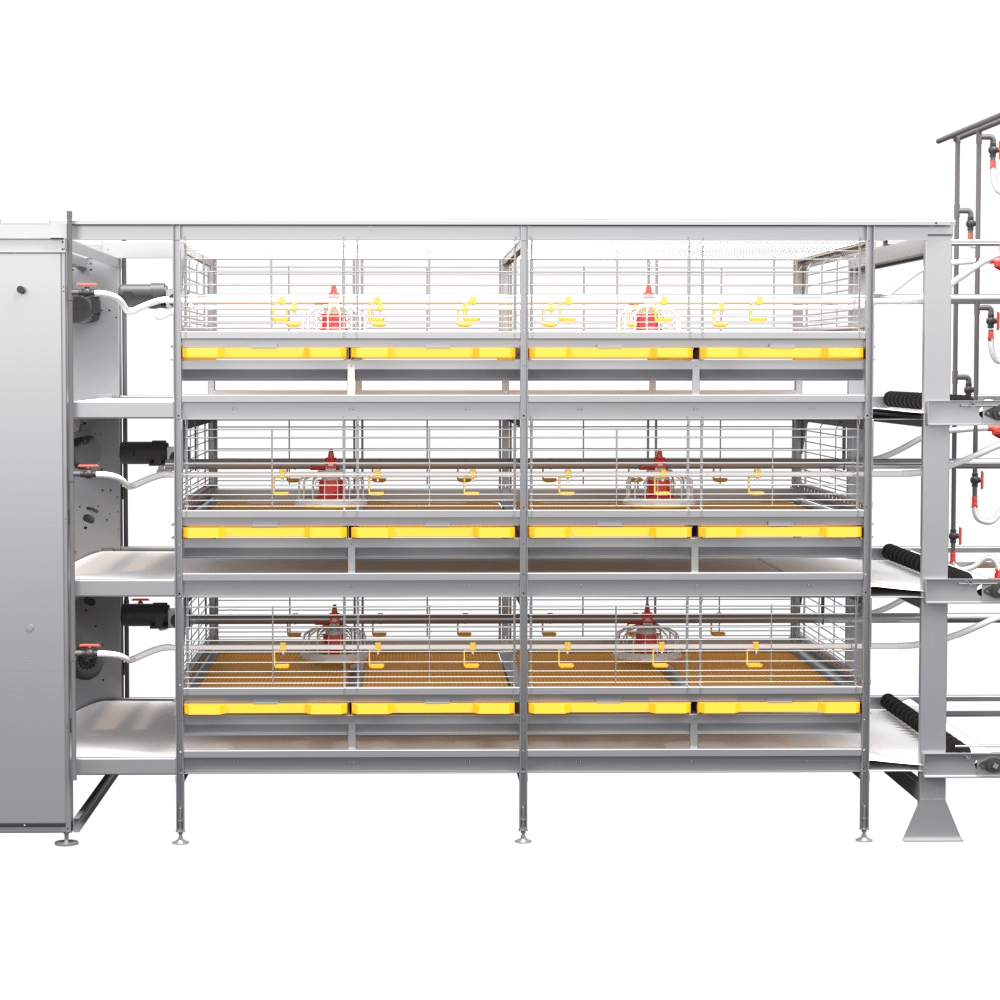

Product Advantage

1. Cage mesh + frame

- Cage size: perfectly fitted to match the number of birds (raising density:50kg/㎡).

- Surface treatment: hot galvanized with uniform 275g zinc coating, good anti-corrosion quality.

2. Automatic feeding

- Silo: weighing device is included for daily records of feed consumption.

- Pan feeding: The height is adjustable to feed chickens at different ages.

- Feed sensor: IFM®.

- Feed pipe: hot galvanized.

- Spiral: imported from South Africa.

- This mechanism guarantees a uniform distribution of feed over the whole system.

3. Automatic drinking

- Lifting system for every water dispenser allows chickens to drink at the correct height.

- Two different water supply lines are placed in each cage with 12 pcs drinkers.

- 360°water supply of the nipples.

- Supply Doser, filter, and pressure gauge.

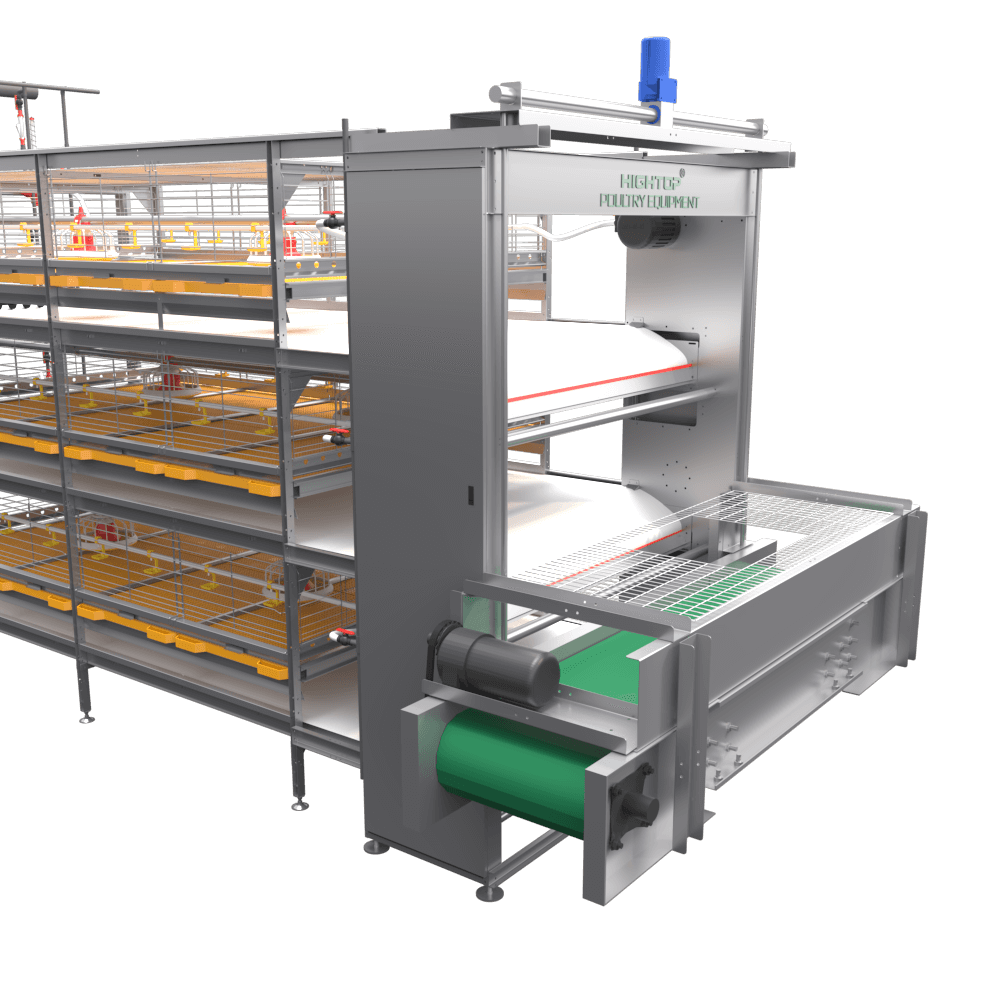

5. Automatic bird-harvesting

- Plastic slat floor: PP raw material, soft and strong, hurt chicken breasts and feet; Easily pulled out.

- Flexible bird-harvesting time: Qualified chickens are taken out first. Chickens below the slaughter weight can continue to be raised for 1-2 days.

- lifting system at the final part can transport chickens from each tier outside the house.

- Bird-harvesting speed: about 6000 birds per hour.

- PVC conveying belt with 600mm width.

6. Automatic ventilation

- Cone fan: pass dynamic balance test.

- Cooling pad: with anti-rat mesh.

- Air-inlet window: with anti-bird mesh.

- Deflector: prevent cold air on chickens directly, avoid cold stress.