Egg production remains one of the most profitable and resilient sectors in agriculture, but success depends on more than simply raising hens. Today’s commercial poultry operations face rising feed costs, higher labor expenses, and growing consumer expectations for both product quality and animal welfare. To maximize profitability, poultry farmers must balance biological efficiency with smart management and strategic investments in technology.

The following 10 proven tips form an integrated framework that helps egg producers increase efficiency, reduce costs, and improve flock performance.

1. Optimize Feed and Nutrition for Maximum Conversion

Feed accounts for 60–70% of total production expenses, making it the single most important variable cost in egg farming. For this reason, the Feed Conversion Ratio (FCR)—the amount of feed required to produce a dozen eggs—is the most critical profitability metric.

A balanced diet for laying hens should contain:

| Nutrient | Recommended Level | Function |

|---|---|---|

| Protein | 16–18% | Supports egg production and feather growth |

| Carbohydrates | 50–60% | Provides energy for body functions and egg production |

| Fats | 3–5% | Supplies energy and aids absorption of vitamins |

| Calcium | 3.5–4.5% | Essential for strong eggshells |

| Phosphorus | 0.35–0.45% | Works with calcium for shell strength and energy |

Don’t overlook essential amino acids such as lysine, methionine, and cystine, as well as vitamins like Vitamin D3. Proper nutrition directly translates into higher egg yield, stronger shells, and reduced mortality.

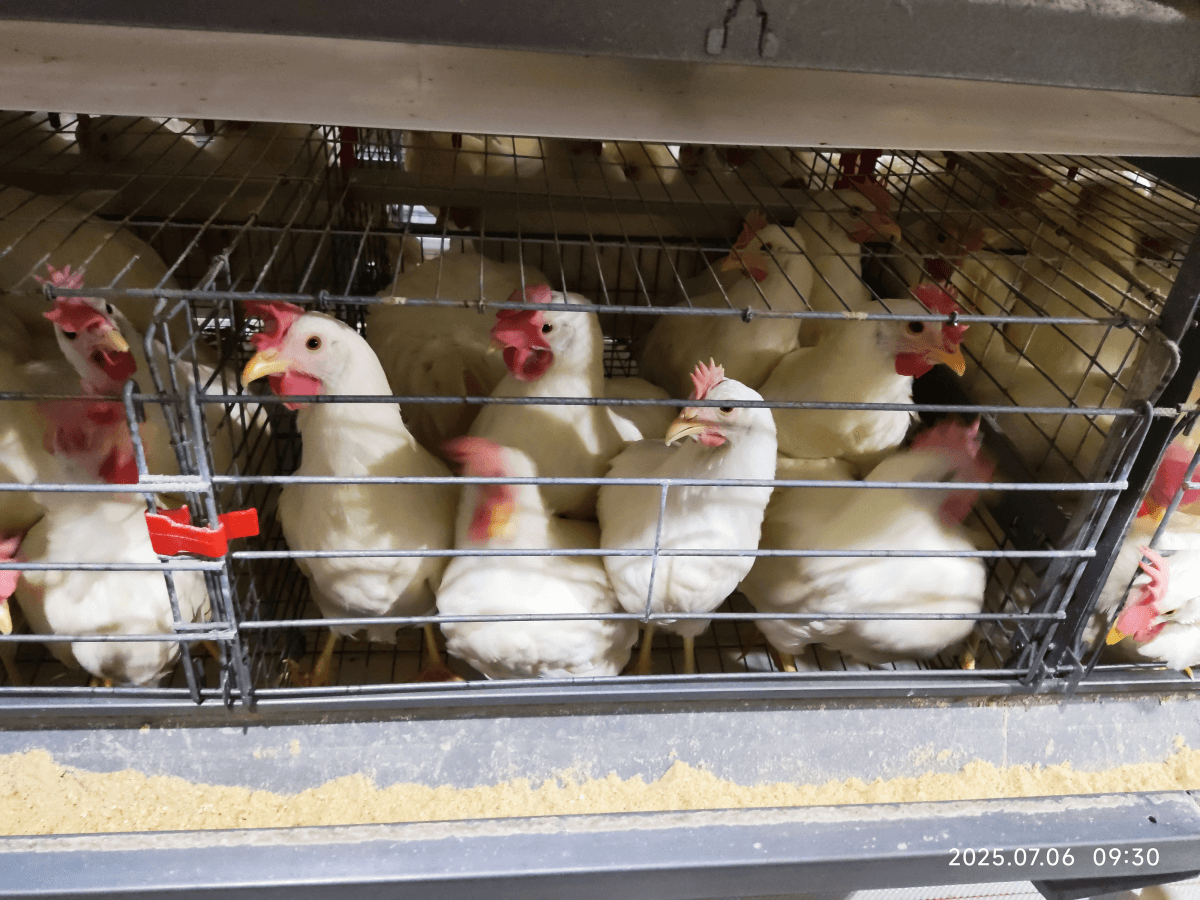

2. Master Environmental and Housing Controls

The physical environment of the hen house directly impacts productivity. Poor ventilation, fluctuating temperatures, and inconsistent lighting all lead to stress, lower egg output, and higher mortality.

Target conditions include:

| Environmental Factor | Optimal Range | Implementation |

|---|---|---|

| Temperature | 15–18°C (cool) or 18–24°C (moderate) | Heaters, fans, evaporative cooling, misters |

| Humidity | 40–60% | Ventilation, misters, or dehumidifiers |

| Lighting | 14–16 hrs/day | LED or fluorescent lights with timers |

| Ventilation | 5–7 air changes/hour | Fans, ducts, exhaust systems |

Maintaining these parameters reduces stress, prevents respiratory disease, and supports peak laying rates.

3. Implement a Stepped Lighting Program

Light is one of the most important environmental cues for laying hens, directly stimulating the pituitary gland and reproductive system. To avoid stress and maximize productivity:

- Begin increasing lighting gradually once hens reach 18 weeks of age.

- Add light in small increments until the flock reaches 16 hours of light per day.

- Keep intensity uniform, at a brightness where a newspaper can be easily read inside the house.

This gradual approach mimics the natural onset of spring, stimulating ovarian development while avoiding the production drop or prolapse issues caused by sudden lighting changes.

4. Provide Cool Drinking Water

Hydration is especially critical during hot summer months. Chickens lack sweat glands, so they rely heavily on respiration and drinking water to regulate body temperature.

Best practices include:

- Shading water pipes and storage tanks.

- Flushing warm water from lines regularly.

- Adding Vitamin C or electrolytes to water during extreme heat.

Cool water helps birds maintain feed intake, prevents sharp drops in egg production, and supports strong shell quality even under heat stress.

5. Use Midnight Light Supplement Feeding

Heat stress often suppresses feed intake during the day. A practical solution is to:

-

Provide 1 hour of light and feed between 1–2 a.m. (the coolest time of day).

This allows hens to eat when they are most comfortable, ensuring adequate intake of calcium and other nutrients necessary for eggshell formation. The result is fewer thin-shelled or broken eggs and more consistent production.

6. Add Fat and Baking Soda During Hot Seasons

Nutrition adjustments during heat stress can make a significant difference:

- Fat (1–2%): Provides energy without raising body heat load. Helps sustain egg production even when feed intake is low.

- Baking Soda (0.2–0.3%): Balances pH levels during panting-induced alkalosis, improves calcium absorption, and strengthens eggshell quality.

These small dietary modifications can protect profits during extreme summer conditions.

7. Embrace Automation for Labor Savings

Automation is no longer optional—it is a necessity for modern egg farms. Automated feeders, waterers, manure removal belts, and egg collection conveyors drastically reduce manual labor while improving efficiency.

Key financial benchmarks:

| KPI/Metric | Benchmark | Profitability Impact |

|---|---|---|

| Labor Cost Reduction | 60–70% | Cuts largest expense |

| Payback Period | 2–3 years | Fast ROI |

| Management Ratio | 2–3 operators for 20,000 birds | High scalability |

Automation not only saves money but also reduces egg breakage, ensures consistent nutrition, and boosts saleable Grade A eggs.

8. Eliminate “Empty Trough” Time

Feeding schedules must avoid long periods of empty feeders, which cause stress and uneven nutrient intake.

Best practice:

-

Keep feed available throughout the day, but ensure troughs are mostly empty one hour before the next feeding.

This encourages hens to consume a balanced ration (instead of selectively picking corn and leaving minerals behind), ensuring consistent nutrition and stable egg production.

9. Implement a Rigorous Biosecurity Plan

Disease is the single greatest threat to profitability in egg farming. A strong biosecurity program should cover:

- Farm Layout: At least 1 km away from other poultry farms; fenced perimeters to restrict access.

- Controlled Access: Clean and dirty zones; foot baths; farm-specific clothing and boots; strict visitor protocols.

- Flock Management: “All-in, all-out” systems to prevent cross-contamination between age groups.

- Vaccination: Programs against Newcastle disease, avian influenza, and other regional threats.

- Quarantine: Isolate new birds for 2 weeks before introducing them to the flock.

Preventing disease saves far more money than treating it, protecting both animal welfare and long-term profitability.

10. Transform Waste Into Revenue

Chicken manure is often seen as a disposal problem, but in reality, it can be a profitable by-product. Properly managed, it becomes a high-value organic fertilizer.

Steps for composting:

-

Mix manure with carbon-rich material (2 parts brown to 1 part green).

-

Maintain compost temperatures of 140–160°F for several days to kill pathogens.

-

Age compost for at least 90 days before use or sale.

Benefits include:

- Eliminating waste removal costs.

- Generating additional income by selling organic fertilizer.

- Improving soil quality if applied directly on the farm.

By shifting perspective, waste management transforms from a liability into a new revenue stream.

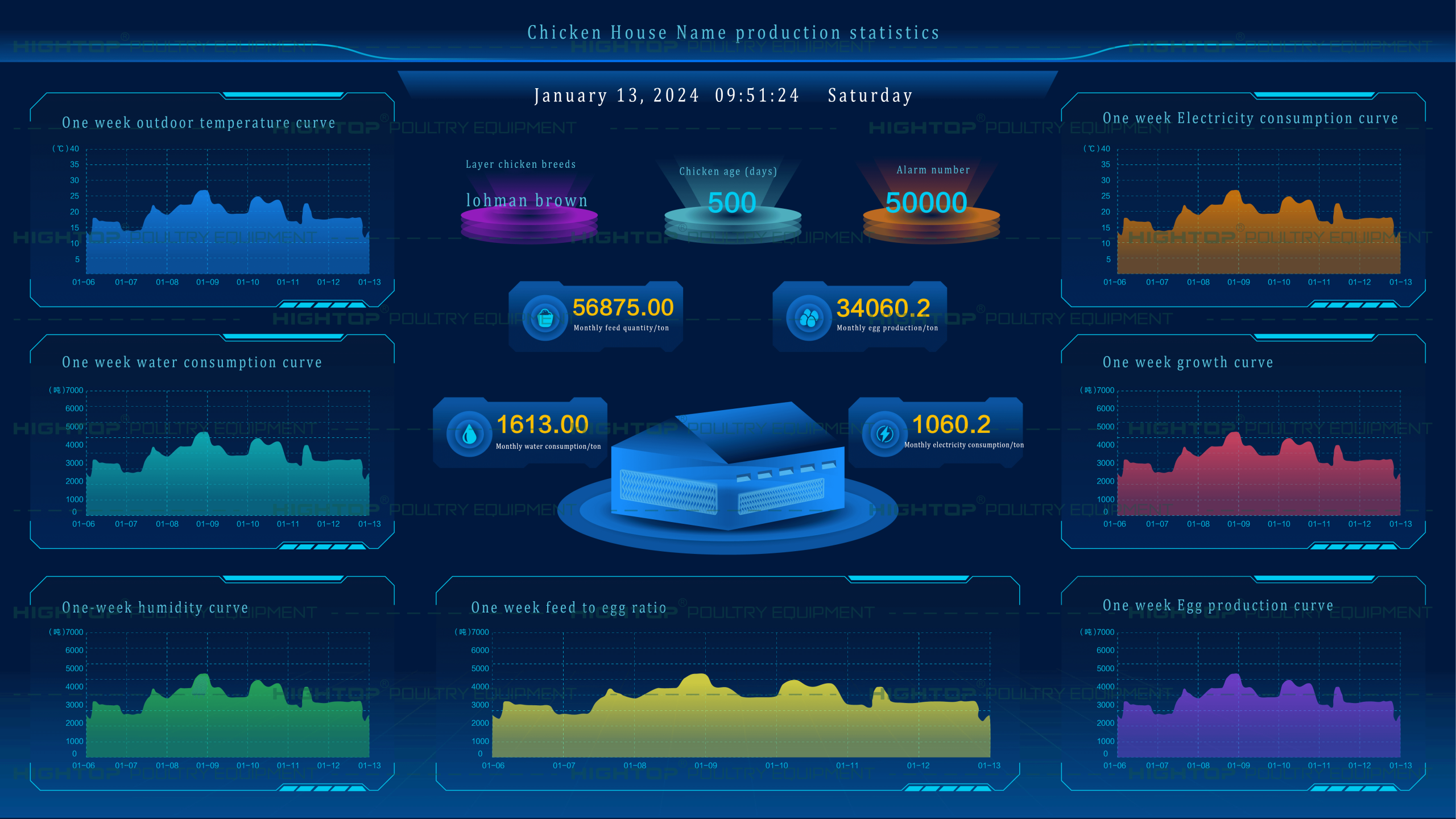

11. Lean and Smart Managment System Increases Farming Profit

You can check it conveniently via your cellphone or computer.|

It helps incease framing profit by following ways:

1. Precisely Reduce Operating Costs

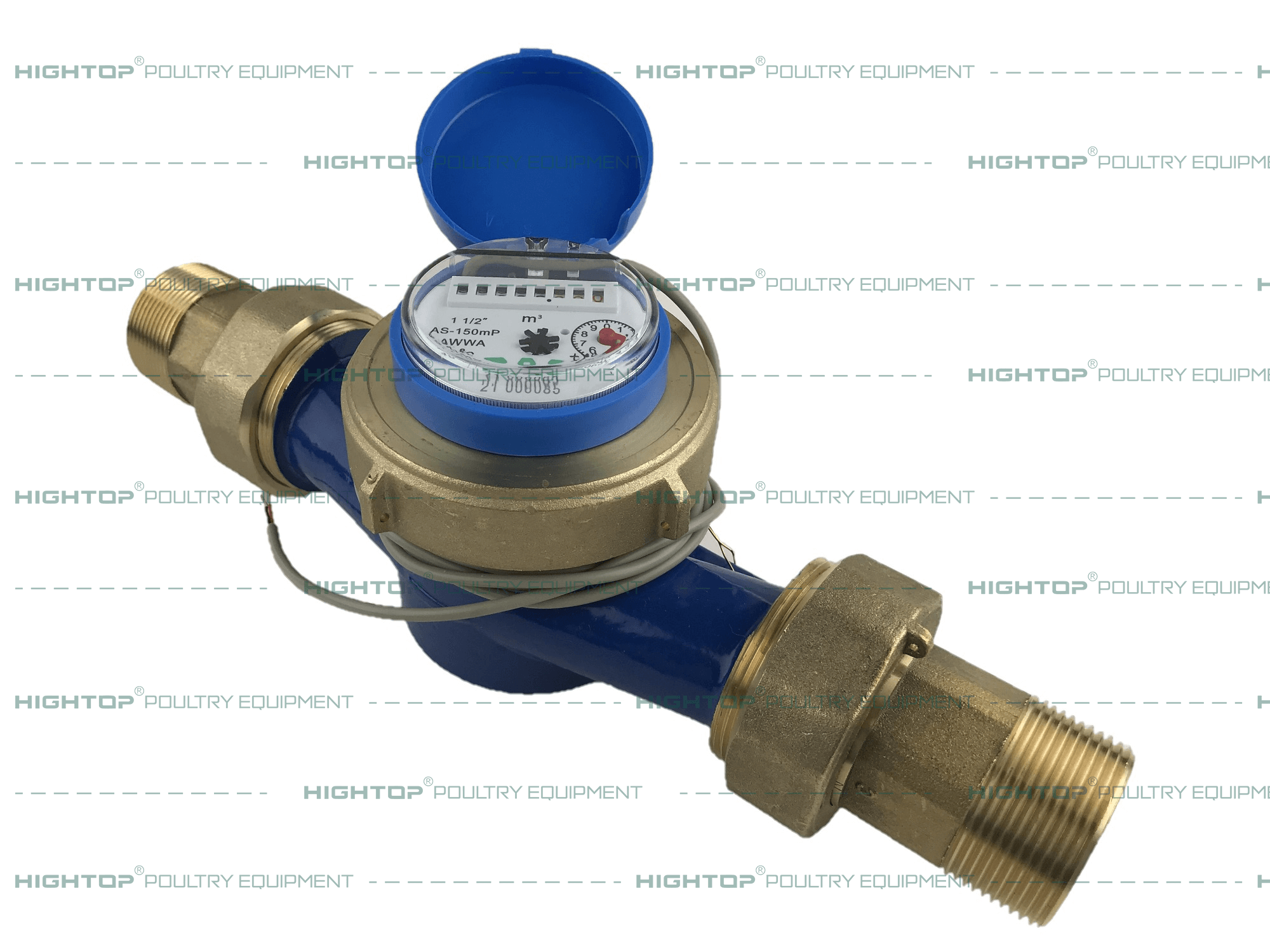

- Water and Electricity Saving: The system monitors water and electricity consumption in real time, identifies anomalies (such as pipe leaks or equipment idling) through data analysis, and issues timely alarms, directly reducing water and electricity costs.

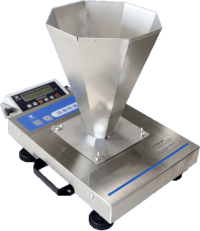

- Optimized Feed Input: The system accurately records the feed input for each poultry house and correlates it with output data such as egg production and weight gain. This avoids feed waste or underfeeding, identifies the optimal input-output ratio, and significantly reduces the largest cost item—feed costs.

- Reduced Labor Costs: Automated data collection replaces traditional manual meter reading and house inspections, reducing manpower requirements and improving work efficiency, allowing staff to focus on management and emergency response.

2. Directly Increase Core Output (Eggs/Poultry)

- Improved Egg Production Rate and Quality: The system correlates environmental data (temperature and humidity) with egg production, egg weight, and broken egg rate in real time. By maintaining the optimal egg-laying environment, it stabilizes and increases egg production rate while reducing broken and soft-shelled eggs, improving product grade and selling price.

- Promoting Healthy Weight Gain: For poultry farming, a stable and optimal environment reduces energy stress in livestock and poultry, allowing nutrients to be used more effectively for weight gain, shortening the slaughter cycle, and improving feed conversion rate.

3. Optimizing Flock Health and Welfare, Reducing Losses

- Disease Early Warning: Water and feed intake are barometers of livestock and poultry health. Once the system detects an abnormal decrease in water/feed intake in a poultry house, it can immediately issue a health warning, enabling early detection, isolation, and treatment of diseases, significantly reducing mortality and medical costs.

- Environmental Stress Control: Real-time monitoring of temperature and humidity triggers an alarm immediately if set thresholds are exceeded, reminding managers to ventilate or maintain warmth, preventing mass illness or death of livestock and poultry due to heat or cold stress, directly reducing unexpected losses.

4. Achieving Data-Driven Scientific Decision-Making

- Performance Comparison Analysis: The system can horizontally compare production data (such as feed conversion ratio and survival rate) of different poultry houses and different batches of livestock and poultry, helping managers identify best practices and promote them throughout the farm.

- Optimize Production Planning: By predicting peak egg production and slaughter times based on historical data, procurement, sales, and logistics can be arranged more accurately, reducing inventory pressure and seizing opportunities during periods of high market prices.

5. Enhance Risk Warning and Emergency Response Capabilities

- Prevent Major Accidents: Monitoring circuit temperature, water levels, etc., can effectively provide early warnings of major risks such as fires and water outages, avoiding catastrophic losses.

- Remote Monitoring and Management: Managers can remotely monitor the entire operation via mobile phone or computer, enabling rapid response to emergencies even when not physically present, thus reducing risk.

Conclusion: A Framework for Long-Term Profitability

Egg farming today is no longer about tradition—it’s about precision, efficiency, and adaptability. Long-term profitability depends on a combination of strategic nutrition, environmental control, automation, biosecurity, and record-driven management.

The 10 tips outlined above are not isolated tactics but a holistic framework. By implementing them consistently, farmers can:

-

Lower feed costs.

-

Improve egg production rates.

-

Protect flock health and welfare.

-

Save labor through automation.

-

Generate new income streams from waste.

In an increasingly competitive market, the poultry farmers who embrace these best practices will not only survive but thrive, securing profitability and resilience for the years ahead.