A Type Fully Automatic Layer Chicken Equipment for Sale

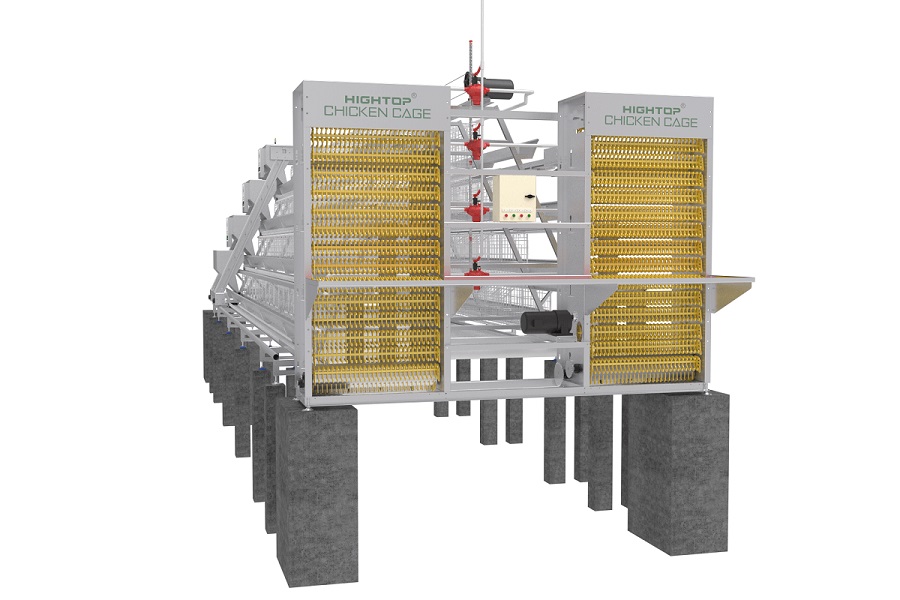

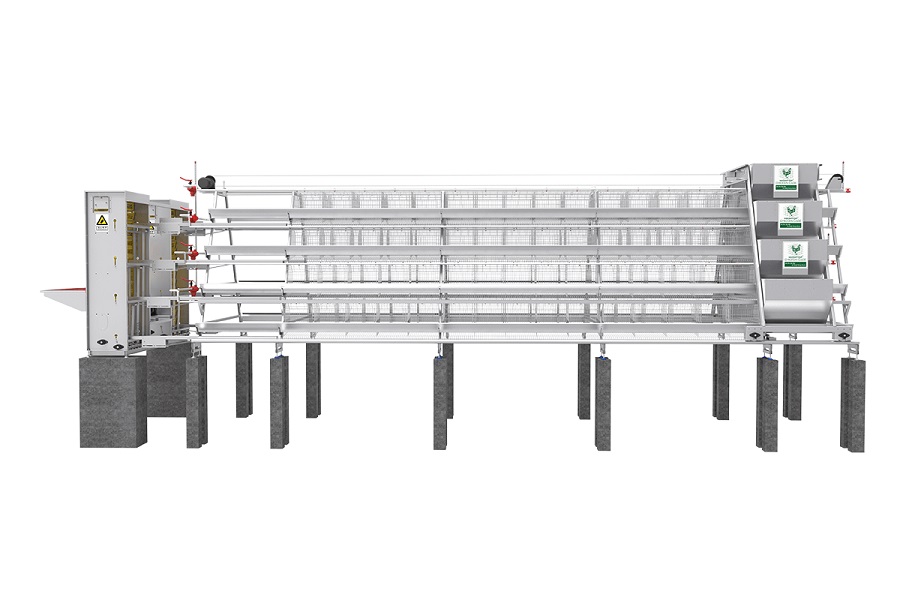

A type battery cage system introduce

A Type Battery Cage Details

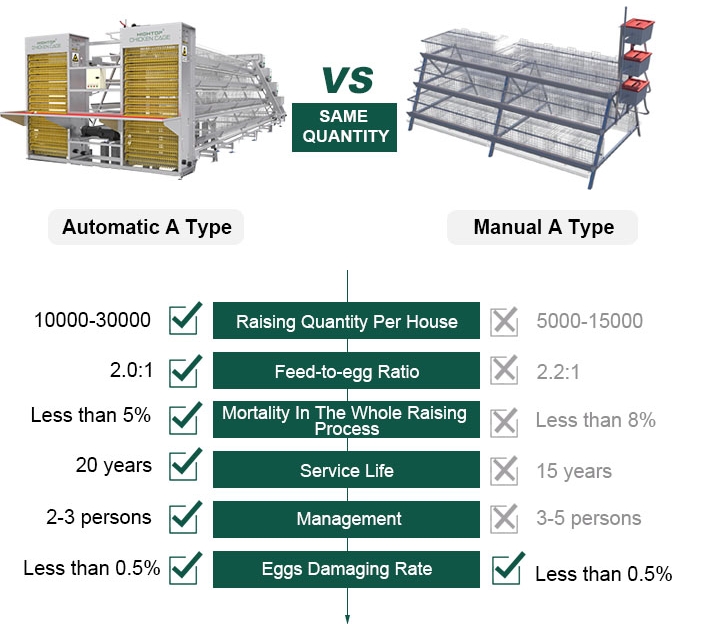

1. ADVANTAGE OF A TYPE FULLY AUTOMATIC CHICKEN EQUIPMENT

2. Different Types of Chicken Houses for A Type Automatic Equipment

3. Who Needs A Type Auto Layer Equipment

4. Advantages of A Type Automatic Chicken Equipment

Higher Feed-to-Egg Ration means your chickens eat less feed but lay more eggs.

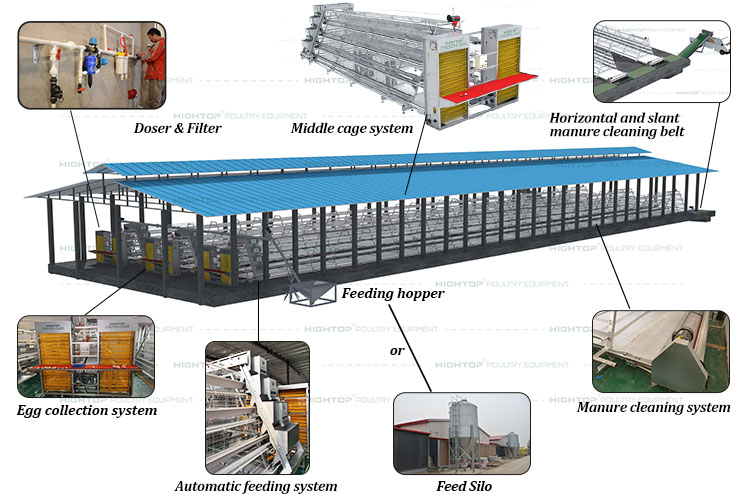

Our auto feeding system can help save your chicken feed.

- Save chicken feed with feed uniform and feed returning device

- Save feeding time with automatic system

- Save labor cost

With auto manure cleaning machine, you can make sure clean and healthy environment for chickens, reducing mortality rate.

- Clean chicken manure timely can reduce ammonia gas that can cause chicken’s respiratory diseases, reducing mortality.

- Clean chicken manure for three times, ensuring the belt is clean.

With automatic egg collection system, you don’t need workers to pick up eggs by manual, so you can:

- Reduce egg broken rate (less than 0.5%)

- Save labors and time

- Make sure clean eggs

- Cage mesh: hot dipped galvanized, lifespan is 15-20 years

- Cage stand: Zinc Aluminum Magnesium surface treatment, better anti-corrosion quality than manual cage stand. And stand is made of U type steel by molding machine, no welding point, more stable.

- More reasonable cage design: Bigger cage nest size, so you can raise more chickens with same area.

5. More Optional Automatic System

Lighting has very big effect on chicken’s growth.

Proper lighting can increase egg production

- Red light can prolong peak egg laying period.

- Light controller system: Intelligent control of light time and light color.

- Poultry special light, flicker free light.

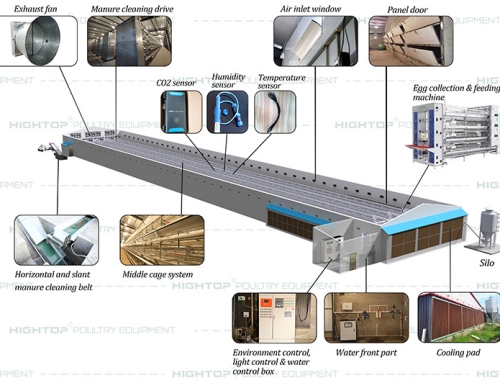

- The whole system include exhaust fan, cooling pad, deflector, air-inlet windows.

- Exhaust fan and cooling pad can maintain optimum temperature range(13″C -26″C), best is 22C.

- Proper temperature can improve the feed conversion ratio, increase egg production.

- Above 26 degrees, it will increase the difficulty for chickens to dissipate heat, which will lead to stress response and increase mortality.

- Above 43″C ,all the chickens will die.

- Exhaust fan and air-inlet windows make sure fresh air come in, and bring out the harmful gas like ammonia gas, ammonia gas which will cause respiratory disease.

- Deflectors change cool air direction, to prevent chickens from catching cold.

Reduce disease and mortality by disinfection, so you can get more chickens survived and chicken eggs.

The horizontal belt takes the chicken droppings out of the chicken house and the slanting belt can take the chicken droppings to the truck directly, so the whole farm has no bad smell and flies.

6. When Can I Get Profit From Raising Chickens?

7. Our Projects

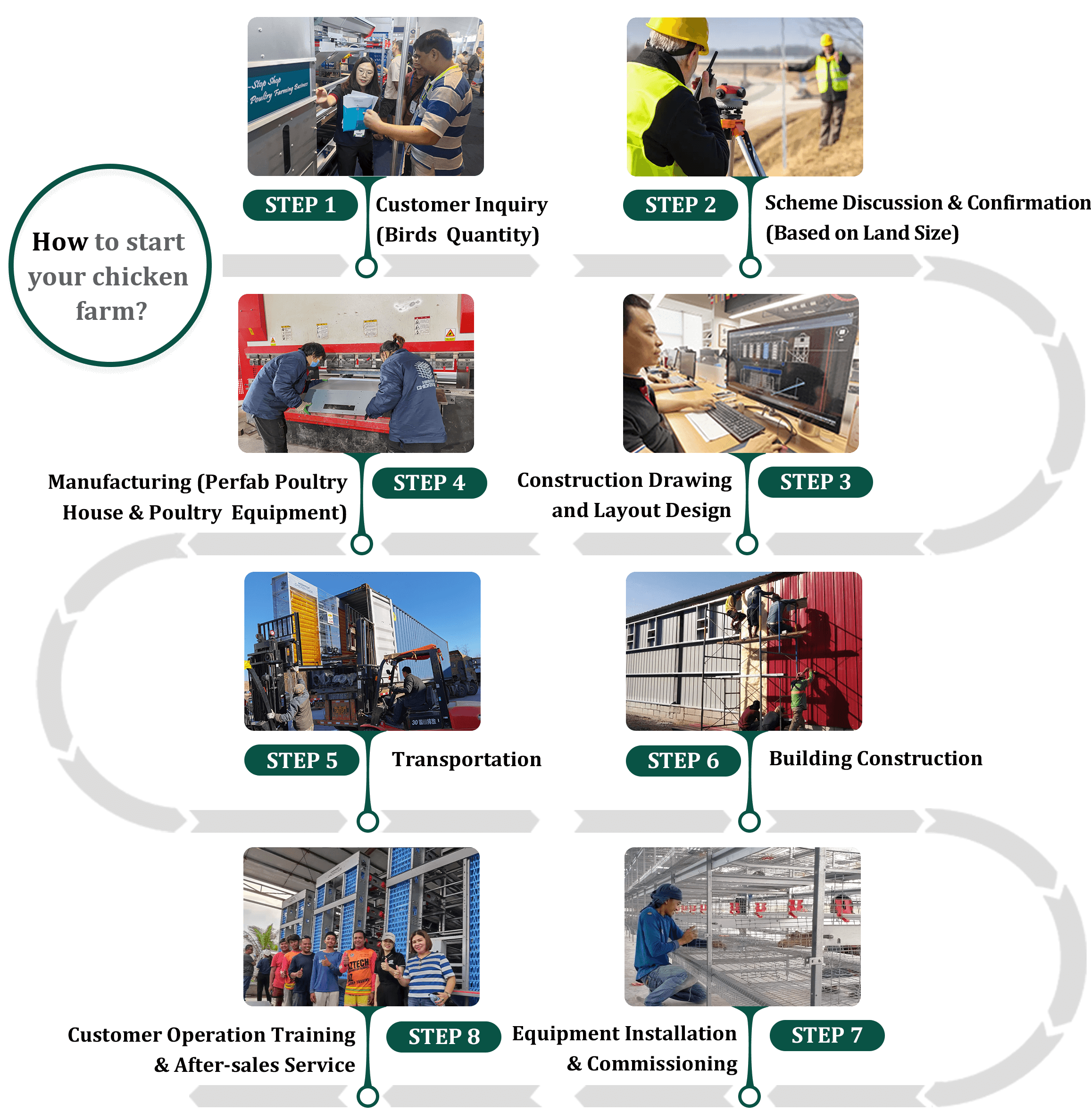

8. Turnkey Solution

Welcome to visit more details through our 720°view of the chicken farm with 1,000,000 layers.

GET A QUOTE

Our fully automated poultry farm equipment is only for medium and large chicken farms with 5,000+ birds, If you own a small farm, automatic battery cage system is not cost-effective, you can use our common chicken cage.

We can ship our equipment to Philippines, Malaysia, Indonesia, Thailand, PNG, Africa, America, etc. Please feel free to contact us.