Closed chicken coops, also known as controlled environment chicken coops, are increasingly popular in modern poultry farming. Compared with traditional open-sided houses, closed coops offer a highly controlled, safe, and efficient environment for poultry. They use advanced technologies and scientific management methods to create optimal conditions for chicken growth, disease control, and environmental sustainability.

Let’s explore the main benefits of closed chicken coops in detail:

1. Precise Environmental Control

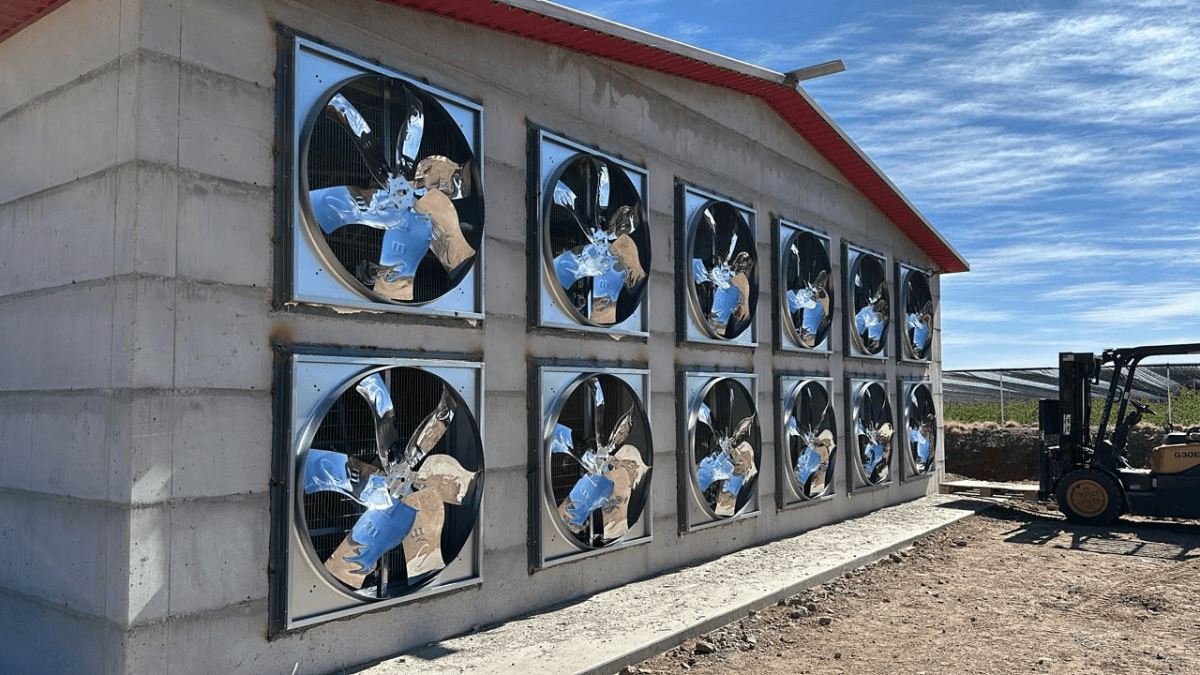

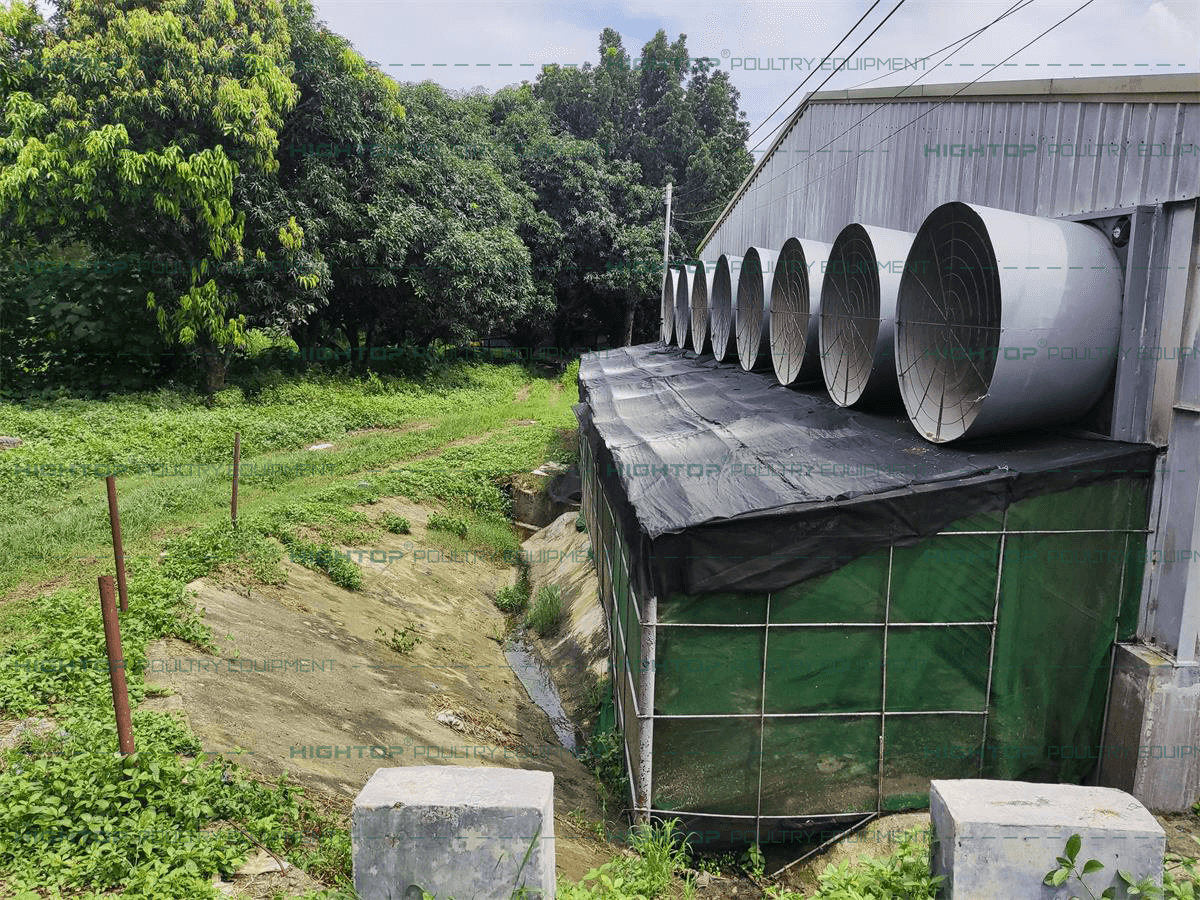

Temperature regulation: Closed coops use ventilation fans, heating systems, and cooling devices like wet curtains to maintain a constant indoor temperature. This helps reduce chicken stress, especially during summer heatwaves or harsh winters. A stable environment ensures consistent weight gain and lower mortality.

Humidity management: Maintaining ideal humidity levels (50-70%) prevents the growth of bacteria and fungi while keeping the chickens’ respiratory tract healthy. Automated sensors can trigger ventilation or humidification when needed.

Air quality: Air inside the coop is continuously refreshed to eliminate ammonia, CO₂, and dust. Proper airflow ensures chickens get enough oxygen while reducing respiratory diseases and improving overall flock health.

2. Advantages of Disease Prevention and Control

Biological isolation: The sealed design prevents wild birds, insects, and rodents from entering, reducing the risk of highly contagious diseases such as avian flu and Newcastle disease.

Convenient disinfection: The structure is easy to clean thoroughly. Disinfection routines can be automated or done with high-pressure sprayers, which help eliminate pathogen residues before new flocks arrive.

Routine biosecurity protocols: Many modern coops include sanitation stations for staff, limiting contamination from humans or equipment brought in from outside.

3. Improve Production Performance

Stable growth environment: Reduced noise, drafts, and abrupt weather changes lead to lower stress levels. As a result, chickens show more uniform growth, better feed intake, and higher survival rates.

Light regulation: Timers and LED systems mimic natural daylight cycles or adjust them based on production goals. For broilers, this accelerates weight gain; for layers, it can increase egg-laying consistency.

Better feed conversion ratio (FCR): Consistent conditions promote better digestion and growth, translating into less feed used per kg of weight gain.

4. Reduce External Interference

Predator prevention: Closed coops provide physical protection against predators such as weasels, snakes, and foxes, reducing unexpected losses.

Human traffic control: Access can be restricted to trained personnel only, which minimizes the chances of external contamination and disease transmission.

Reduced theft and damage: A secure, locked coop protects not only chickens but also valuable equipment from theft or vandalism.

5. Economic Benefits

Energy-saving and high-efficiency: Automated systems for feeding, watering, egg collection, and manure removal reduce the need for manual labor. Over time, this leads to lower operating costs.

Data management: Sensors and smart monitoring tools allow real-time tracking of temperature, humidity, ammonia levels, and even chicken activity. This enables early problem detection and fine-tuned management strategies to maximize profitability.

Higher ROI: Though the setup cost is higher, better flock performance, reduced losses, and labor savings make closed systems more profitable in the long run.

6. Environmental Protection and Sustainability

Manure management: Chicken waste is easier to collect, process, and reuse in a closed system. It can be converted into organic fertilizer or used for biogas, minimizing pollution and turning waste into profit.

Less reliance on antibiotics: With fewer disease outbreaks and better hygiene, the need for antibiotics drops significantly. This supports sustainable, green poultry farming and meets growing consumer demand for antibiotic-free chicken.

Precautions

High initial investment: Building a closed coop requires capital investment in construction, ventilation systems, insulation, and backup power supplies.

Professional management: Operators must understand how to use and maintain the systems. Staff should be trained in both technical operations and biosecurity protocols.

Emergency preparedness: Power outages can cause rapid deterioration in air quality and temperature. A generator or solar backup system is essential for maintaining control during emergencies.

Conclusion

Closed chicken coops offer outstanding advantages in modern poultry farming—from better chicken health to higher productivity and lower environmental impact. While they require more upfront investment and skilled management, the long-term benefits make them a smart choice for serious farmers.

More related questions

How can closed chicken houses reduce disease?

What’s the ROI on automated equipment?

Is enclosed farming suitable for tropical climates?

Leave A Comment