Broiler chicken farming is a profitable and growing sector, but achieving sustainable success depends on making smart, long-term decisions—especially when it comes to equipment. The right farming equipment directly affects production efficiency, labor needs, and long-term profitability. Whether you are just starting or expanding your existing farm, choosing the right equipment requires careful planning and understanding of your farm’s unique circumstances.

This guide will walk you through a practical three-step decision-making process and provide a detailed analysis of available farming models. By the end, you will be equipped to choose the most suitable broiler farming equipment for your operation.

Step 1: Define the Core Decision Triangle

Before looking at equipment options, you need to define three key factors that shape all decisions. Think of these as the Core Decision Triangle:

-

Farming Scale

-

How many chickens do you plan to raise per batch?

-

What is your annual production target?

Scale determines the size of your chicken houses, the complexity of your equipment, and the level of automation required.

-

-

Investment Budget

-

How much are you prepared to invest in equipment?

-

Does your budget include installation, infrastructure upgrades (electricity, ventilation, housing), and maintenance?

Your budget will guide whether you start with basic equipment or advanced automation.

-

-

Labor Situation

-

Are local labor costs high?

-

Can you reliably source and manage a workforce?

Labor availability and cost often determine how much automation you need. In areas with high labor costs or labor shortages, investing in automated systems can save money in the long run.

-

Clearly defining these three elements will narrow your choices and ensure you make an investment that matches your farm’s reality.

Step 2: Understand the Pros and Cons of Each Farming Model

Once your core decision factors are clear, it’s time to evaluate the main farming models. Below is a detailed breakdown of the most common systems, their features, advantages, disadvantages, and best-suited scenarios.

1. Free-Range Farming

-

Core Features: Chickens roam freely on litter inside the house. Equipment is simple, requiring minimal technology.

-

Advantages:

-

Lowest initial investment.

-

Meets certain animal welfare and niche market demands.

-

-

Disadvantages:

-

Lowest stocking density, requiring more land.

-

High feed-to-meat ratio, which increases feed costs.

-

High labor requirements for feeding, manure removal, and catching birds.

-

Higher disease risk due to direct contact with manure.

-

-

Best For:

Small-scale start-ups with a very limited budget or farmers targeting specialty markets (e.g., welfare-based or organic broilers).

2. Standard Cage Farming

-

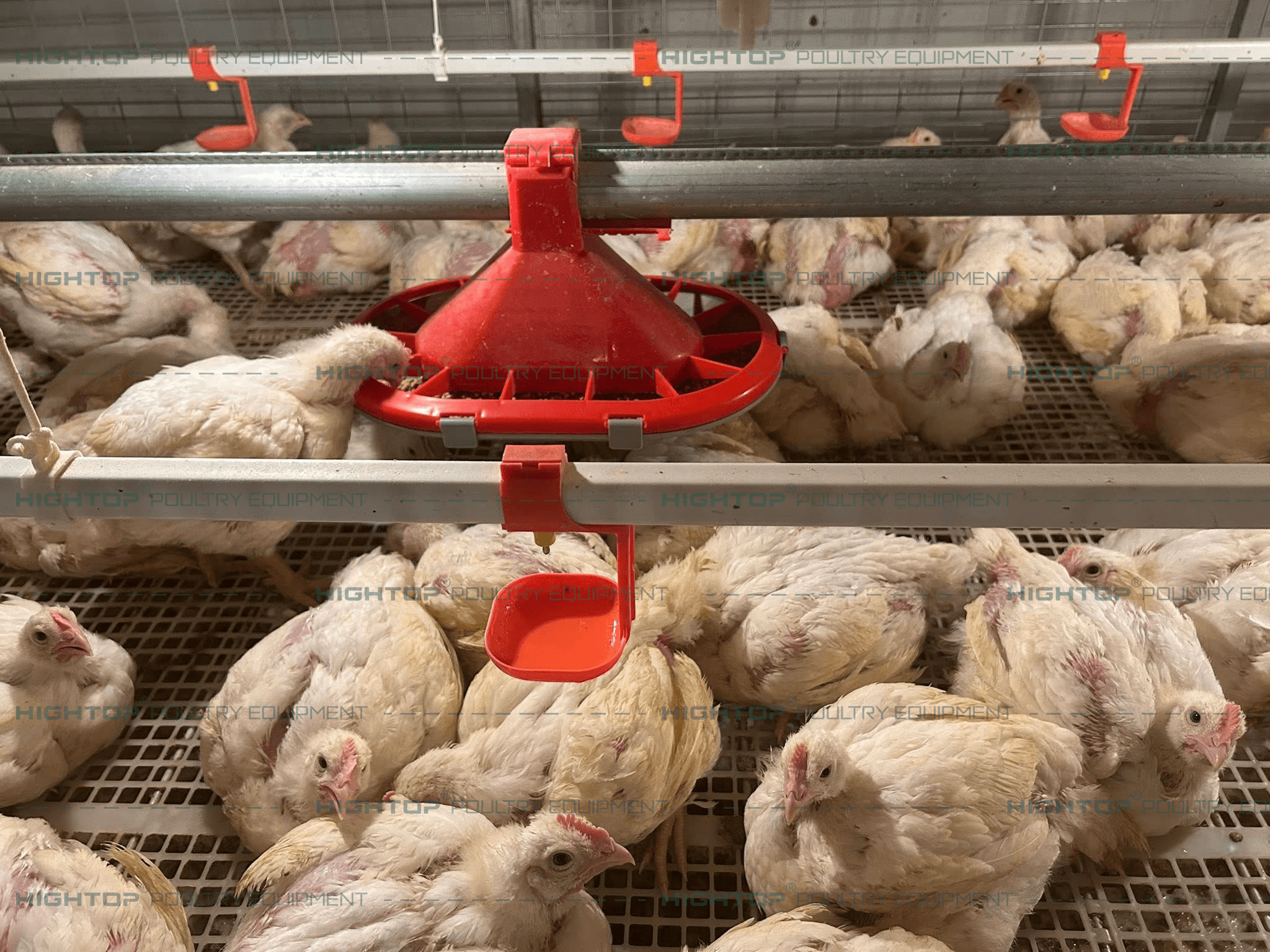

Core Features: Chickens are housed in cages and managed with mostly manual processes for feeding, manure removal, and catching. Available in A-type and H-type designs.

-

Advantages:

-

A-type cages are simple and affordable.

-

H-type cages offer a more stable structure, higher load-bearing capacity, and better use of vertical space with multiple tiers.

-

-

Disadvantages:

-

Low automation results in higher labor requirements and slower operations.

-

Efficiency is limited compared to automated systems.

-

-

Best For:

Small- to medium-sized farms in regions with low labor costs, or farms upgrading old chicken houses with limited budgets.

3. Automated Cage Farming

-

Core Features: Feeding, watering, manure removal, and environmental control are fully automated. Automation dramatically reduces daily labor, improves feed conversion, and creates a cleaner, healthier environment for chickens.

-

Disadvantages:

-

Requires a higher initial investment.

-

Depends on a stable power supply and regular maintenance.

-

Within automated cages, there are three key subcategories, each with different levels of automation and harvesting efficiency:

3.1 Manual Bird-Harvesting Automatic Cages

-

How It Works: Daily feeding, watering, and manure removal are automated, but workers manually catch the chickens during harvesting.

-

Advantages:

-

Lowest investment among automated cages.

-

Solves labor challenges for daily management.

-

-

Disadvantages:

-

Harvesting remains labor-intensive and time-consuming.

-

Higher stress on birds during catching.

-

-

Best For:

Farms that want automated daily operations but have sufficient labor or limited harvesting budgets.

3.2 Automatic Harvesting with Pull-Out Slats

-

How It Works: Chickens are raised in fully automated cages. During harvesting, workers pull out slats in the cage floor, and the birds drop onto a conveyor belt for transport out of the house.

-

Advantages:

-

Reduces harvesting labor by more than 70%.

-

Significantly lowers bird stress and injury rates.

-

Highly efficient and cost-effective for medium to large farms.

-

-

Disadvantages:

-

Higher investment than manual harvesting.

-

Requires workers to operate the pull-out slats.

-

-

Best For:

Large farms seeking a balance of automation, cost savings, and harvesting efficiency.

3.3 Fully Automatic Chain Harvesting

-

How It Works: One-touch operation. The cage floor rises and a chain conveyor automatically transports birds out of the house.

-

Advantages:

-

Minimal labor dependency—just press a button.

-

Highest harvesting speed and efficiency.

-

Lowest biosafety risk.

-

-

Disadvantages:

-

Highest initial investment.

-

Requires advanced maintenance and technical support.

-

-

Best For:

Large-scale farms with strong financial resources, high labor costs, and a focus on ultimate efficiency and biosecurity.

Step 3: Match Your Situation to the Right Equipment

After understanding the equipment options, it’s time to match your farm’s scale, budget, and labor conditions with the most appropriate model.

For Small-Scale Farmers or Starters:

-

Very Limited Budget: Free-range farming is the simplest entry point. While efficiency is low, it allows you to start small and grow gradually.

-

Limited Budget with Efficiency Goals: Consider Standard Cages (preferably H-type) to improve space utilization and lay the groundwork for future upgrades.

For Medium- to Large-Scale Farms:

-

Goal: Automation is essential for profitability at scale.

-

Key Decision: Choose between Manual Harvesting and Automatic Slat Harvesting.

-

Recommendation: Automatic Slat Harvesting is ideal. Although more expensive than manual harvesting, it drastically reduces the most labor-intensive and stressful part of farming—catching birds. Over time, the savings in labor and reduced bird injuries make it the most cost-effective upgrade.

For Large-Scale Farming Groups or Investors:

-

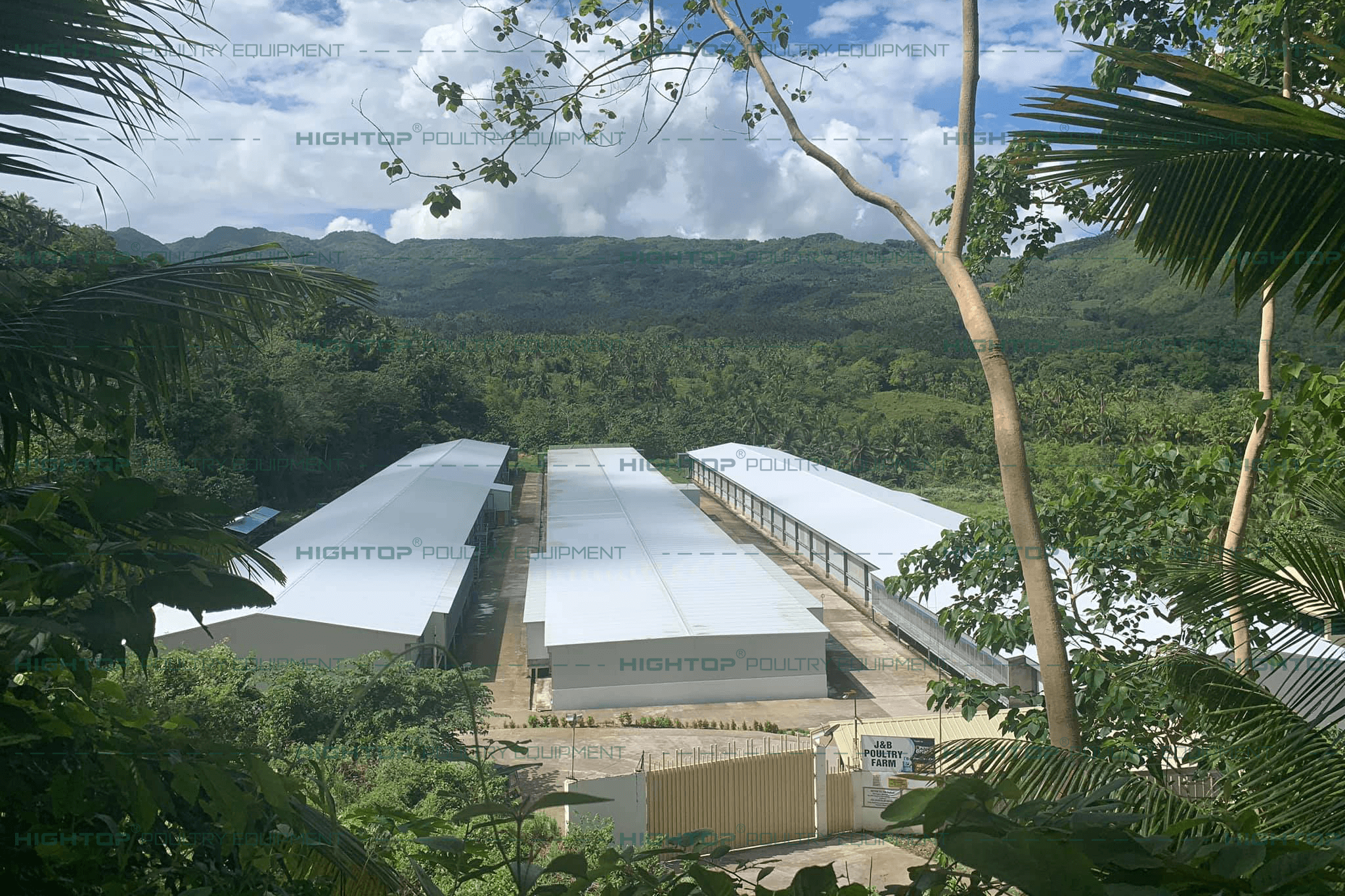

Goal: Build a modern, fully automated chicken farm.

-

Recommendation: Choose the Fully Automatic Chain Harvesting system. At this scale, equipment investment is not just a cost but a strategic advantage. The combination of maximum efficiency, minimal labor dependence, and superior biosafety supports continuous, large-scale production and faster returns on investment.

Why HIGHTOP Broiler Cages Stand Out

When comparing equipment options, brand quality and service are as important as the system itself. Professional brands like HIGHTOP poultry equipment provide key advantages:

-

Sturdy Structure: HIGHTOP’s H-frame design and hot-dip galvanized steel construction ensure long-term durability and stability, even under heavy use.

-

Integrated Automation: Feeding, watering, manure removal, environmental controls, and harvesting systems are designed to work seamlessly together, reducing maintenance issues and improving reliability.

-

Professional Support: Installation, commissioning, training, and after-sales service help minimize operational risks and ensure smooth long-term operation.

Final Thoughts: Focus on the Long-Term Return

There is no single “best” equipment—only the equipment that best fits your farm’s size, budget, and labor conditions. Consider the following key principles:

-

Scale and Budget Drive Your Choice: Start with what you can afford, but aim for scalable systems that allow future upgrades.

-

Prioritize Harvesting Automation for Larger Farms: Harvesting is often more labor-intensive than daily management. Reducing this burden delivers faster payback.

-

Think Beyond the Purchase Price: Calculate total benefits, including labor savings, improved efficiency, and reduced risk over five to ten years.

By carefully aligning your farm’s needs with the right broiler cage system, you can lay the foundation for a profitable, efficient, and future-ready poultry operation.