Product Description

Different poultry farming models place very different demands on both prefab chicken buildings and poultry equipment. Taking a commercial layer farm as an example, a complete operation is not limited to a single chicken house. It typically includes a layer house, egg storage room, feed processing building, disinfection room, electrical control room, and other functional units. Each of these areas has specific structural, environmental, and durability requirements, making the choice of steel structure a critical foundation for the entire farm’s long-term performance.

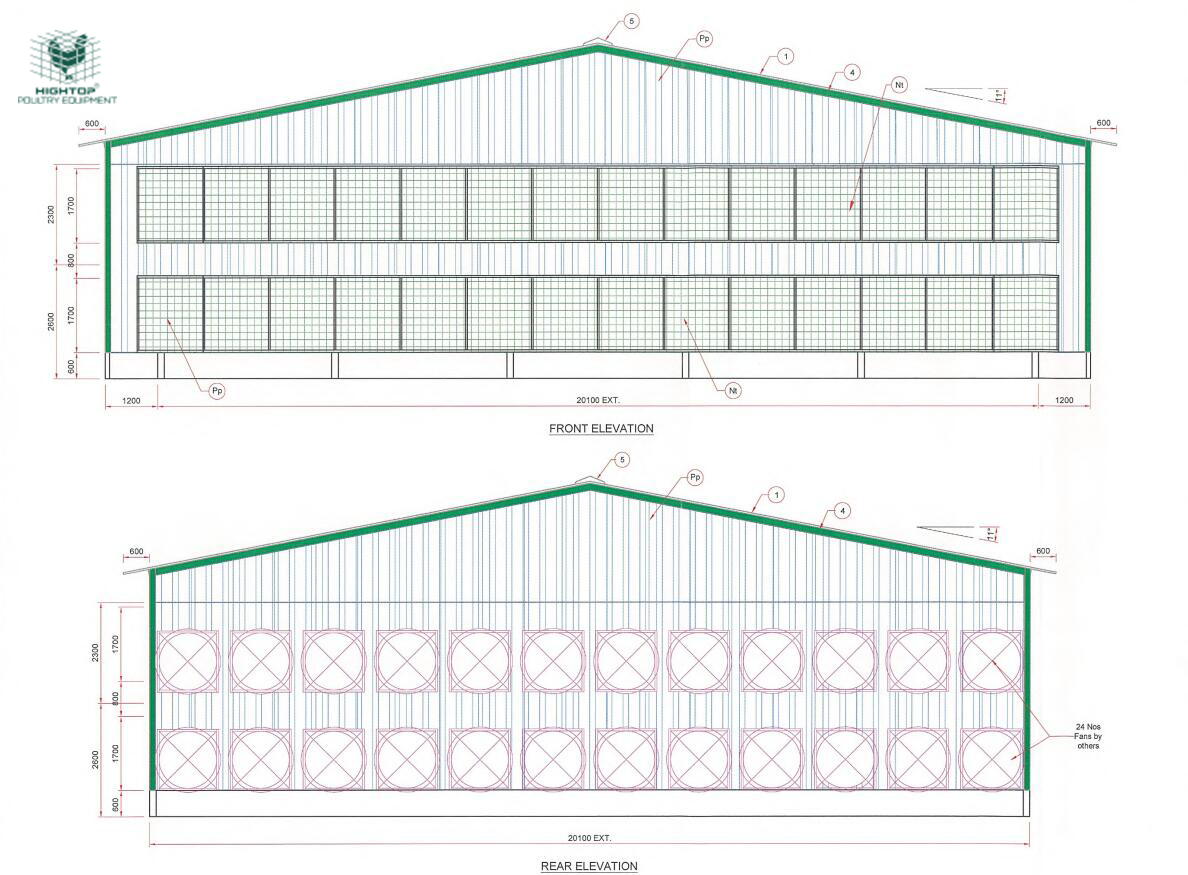

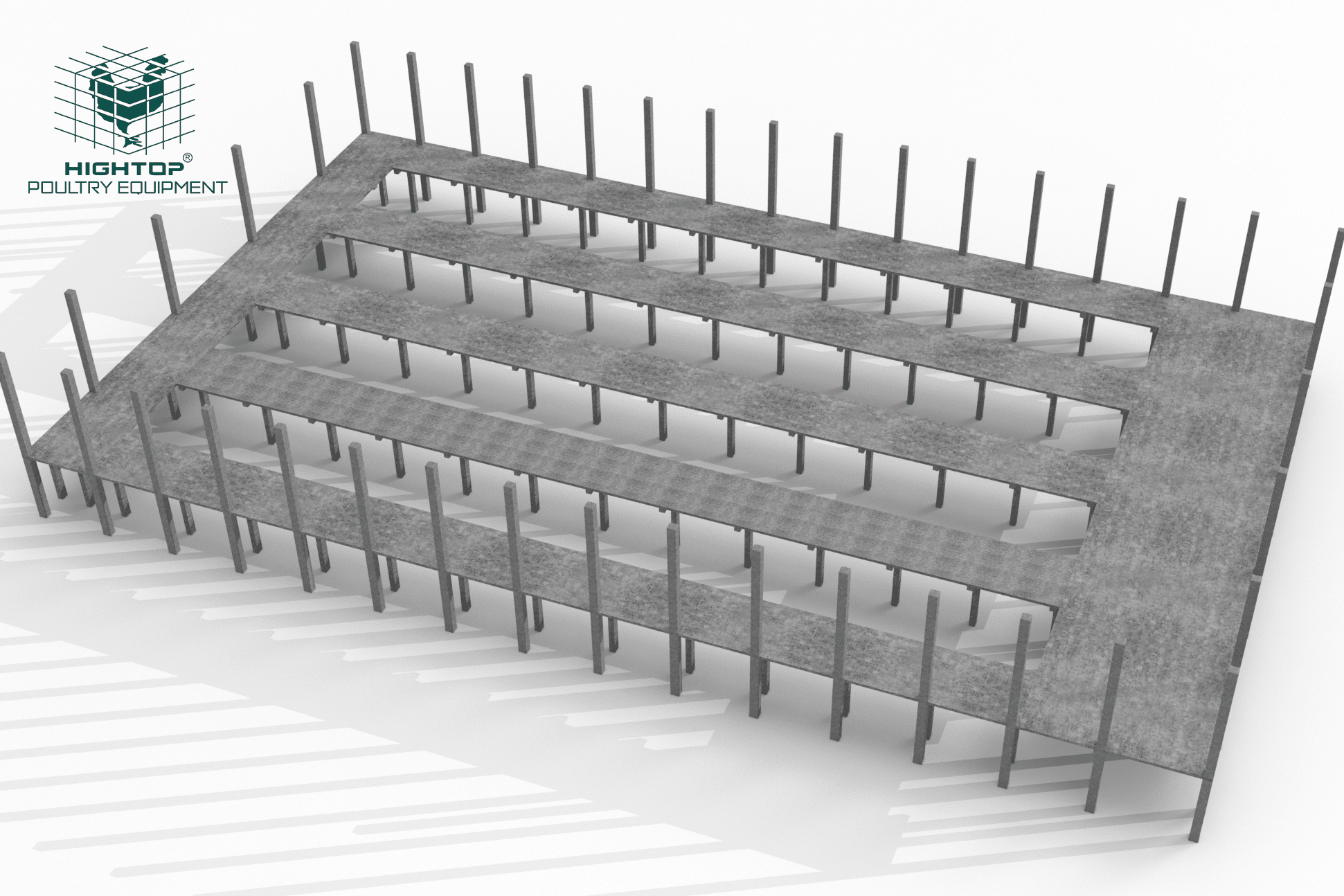

To meet these diverse needs, we provide three specialized types of steel structure poultry houses, each engineered for different wind pressure and snow load conditions. By carefully evaluating your local climate, regional building standards, and farm usage requirements, we recommend the most suitable steel structure solution—ensuring optimal safety, structural stability, and service life. Click here or the button below to learn more about the three steel structure solutions and their advantages, which will help maximize efficiency and return on investment for your poultry farm.

Advantages of Prefabricated Chicken House

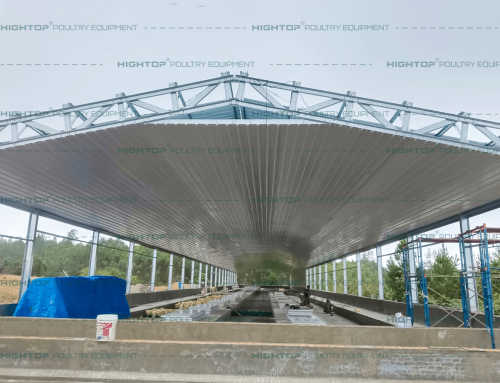

1. Save construction time. It takes about 60 days to finished one traditional cement and concrete chicken house, but it only takes about 20 days to finishthe construction and installation of one prefab chicken house.

2. Easier to install: Construction process is bolt only steel erection. No welding or cutting required at site. Very easy to install.

3 . Reasonable design: Our engineer designs the size and material according to the local geographical and climatic environment, such as earthquake resistance level, wind protection level, and annual temperature range.

Long service life: The Lifespan of prefab steel structure chicken house is more than 30 years.

We can do turnkey projects from design to installation, which can combine the house and equipment together to realize the optimized benefits for the poultry/husbandry house.

1. Whole farm design, if you have the land map

2. Initial design and budget

3. Solution of automatic poultry equipment

4. Detailed construction and installation drawing (3D/CAD/PDF) after contract

5. Online or on-site installation guidance