1. Types of Prefabricated Steel Structure Chicken Houses

Climates vary from country to country. For poultry farming, we mainly categorize environments into high-temperature and dry, high-temperature and high-humidity, distinct seasons, extremely cold regions, and cool regions. For different climates, we can choose between fully enclosed, semi-enclosed, and open-style chicken houses.

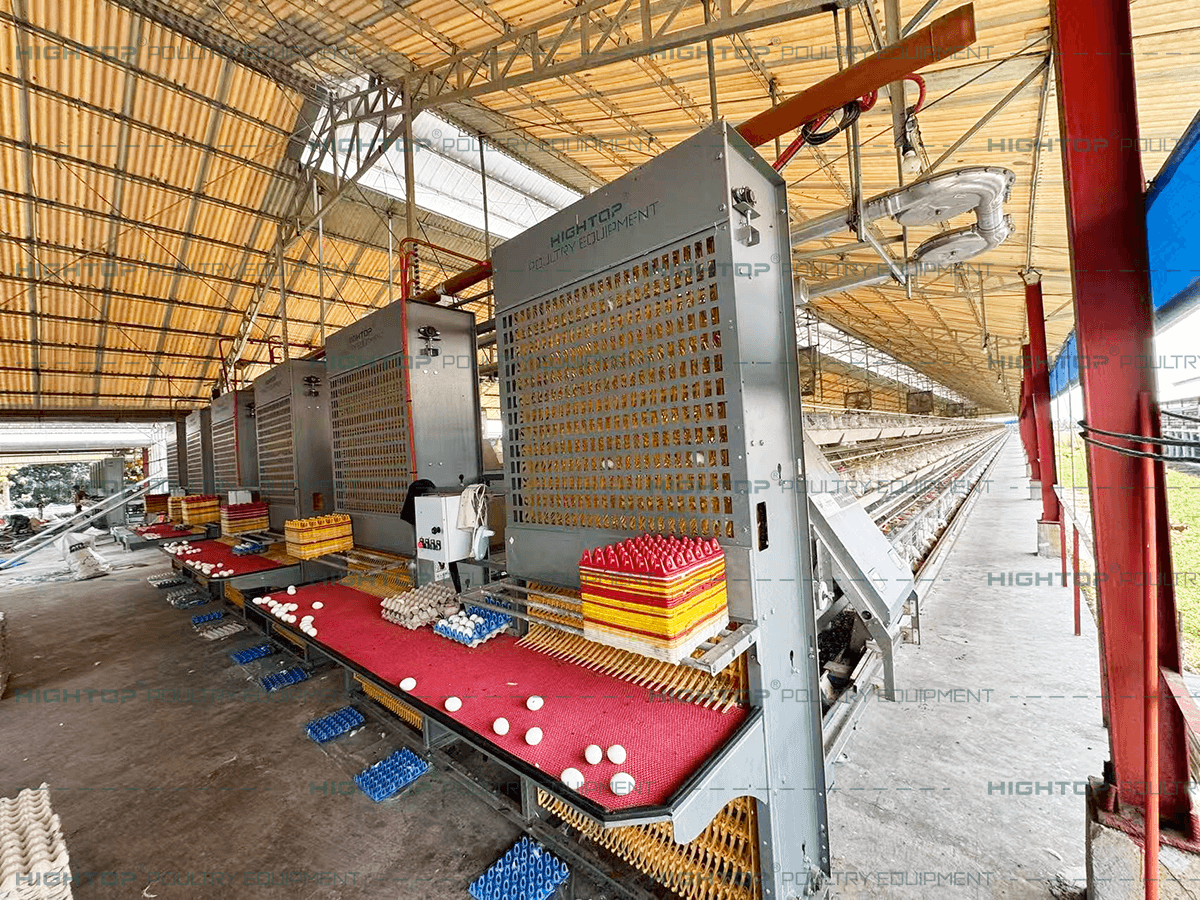

Steel structure chicken houses mainly consist of three parts: a steel frame, an enclosure system, and a ventilation system.

The steel frame maintains the stability of the chicken house, the enclosure system ensures the temperature inside, and the ventilation system ensures the air quality.

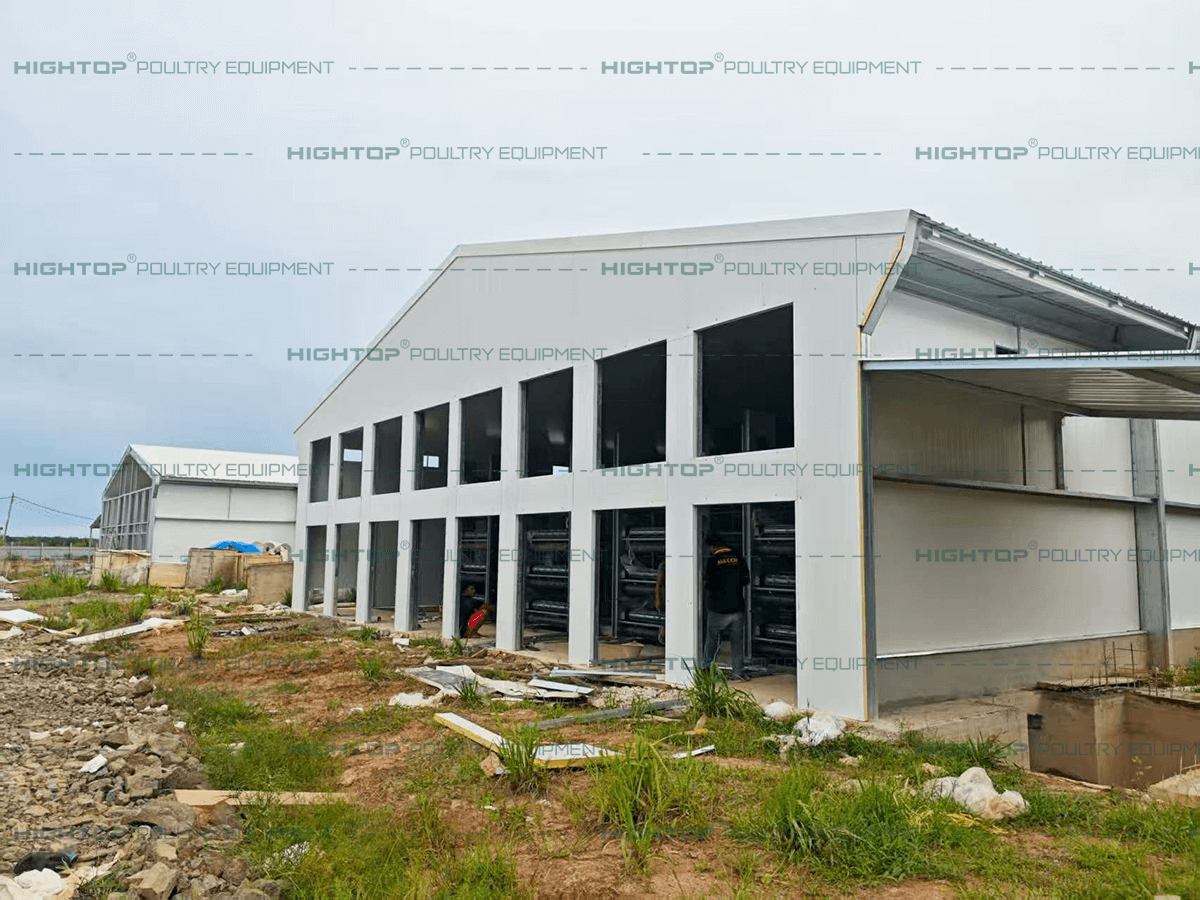

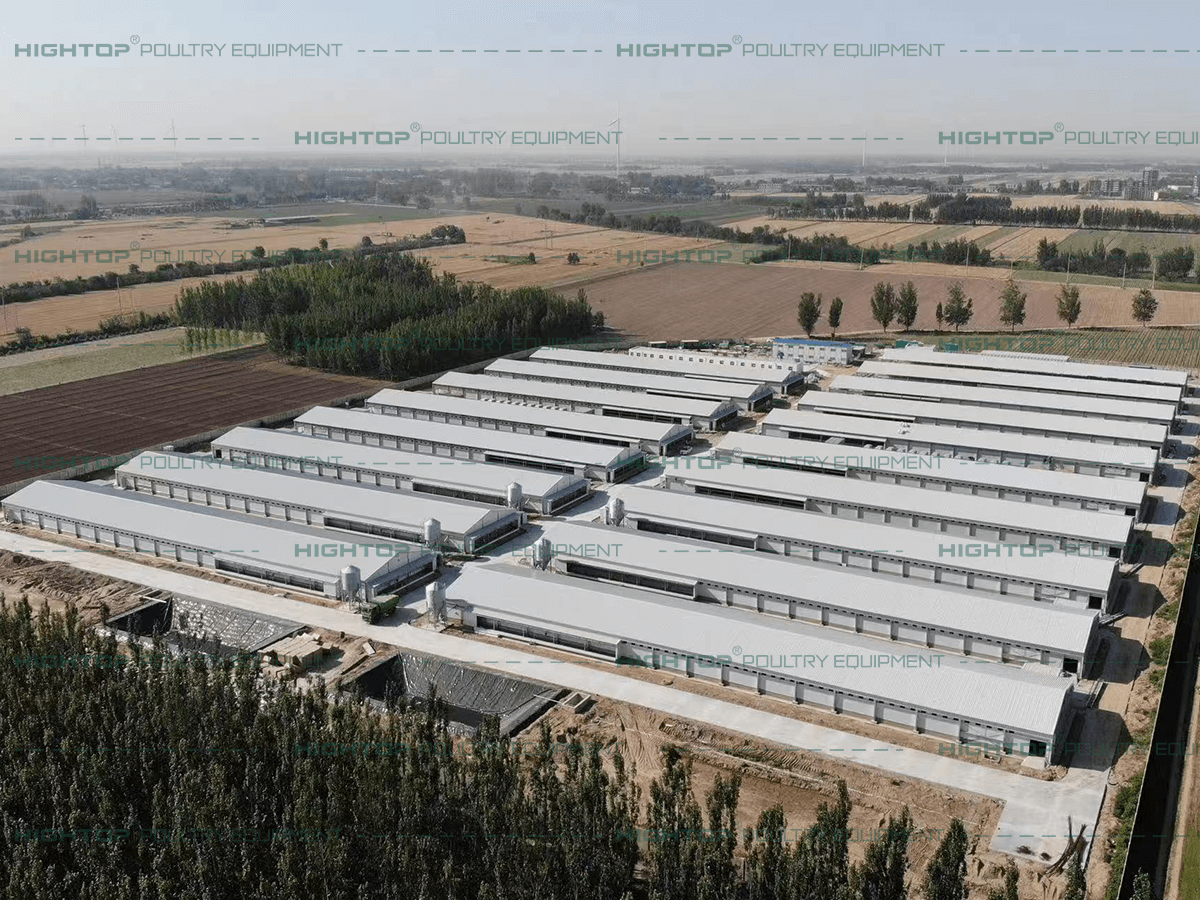

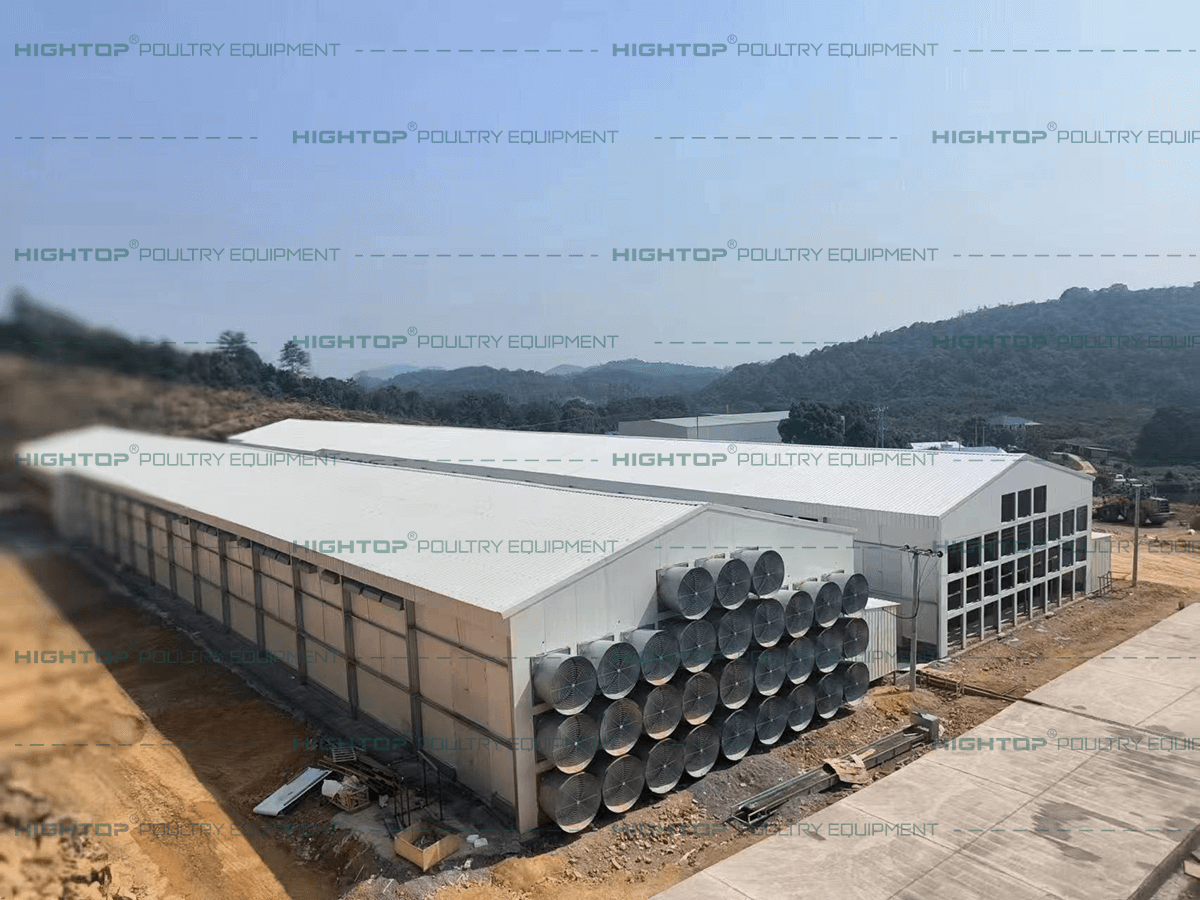

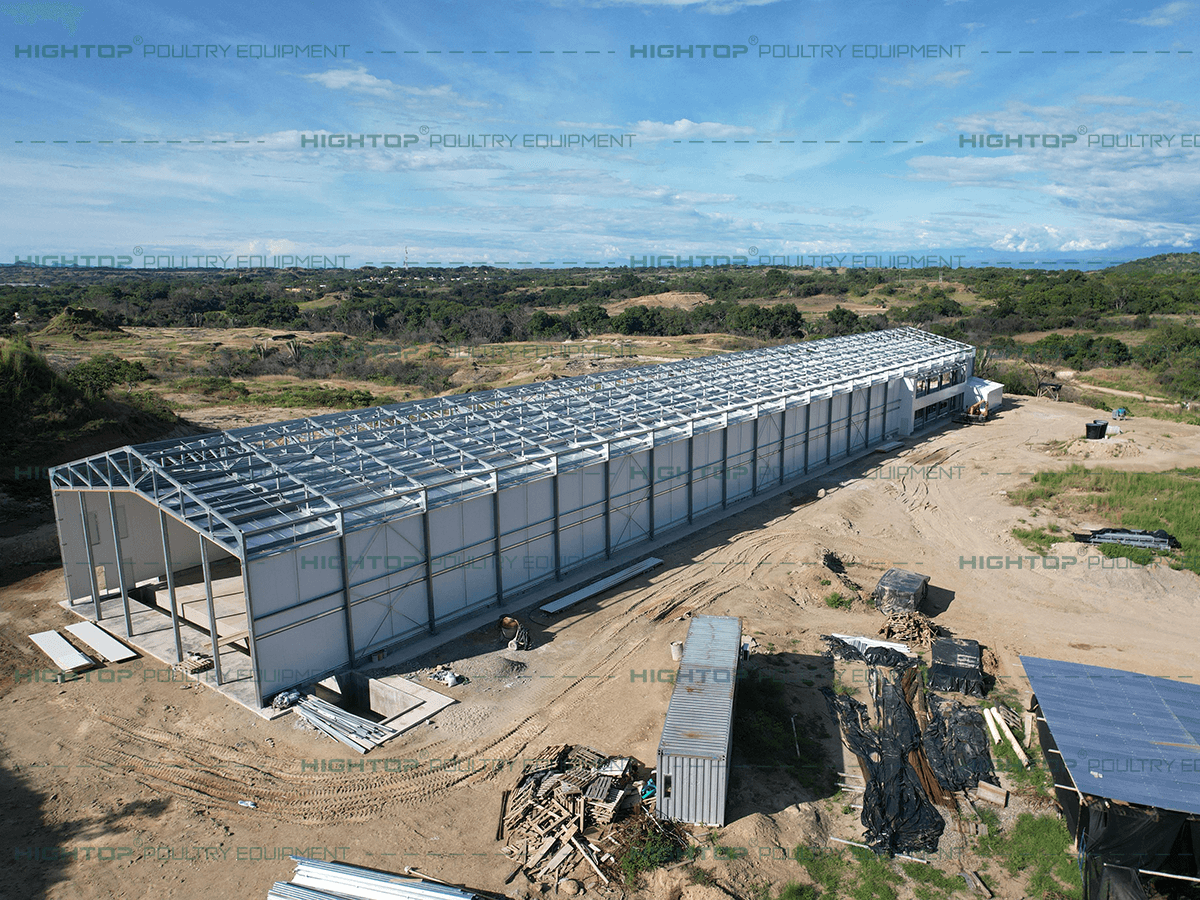

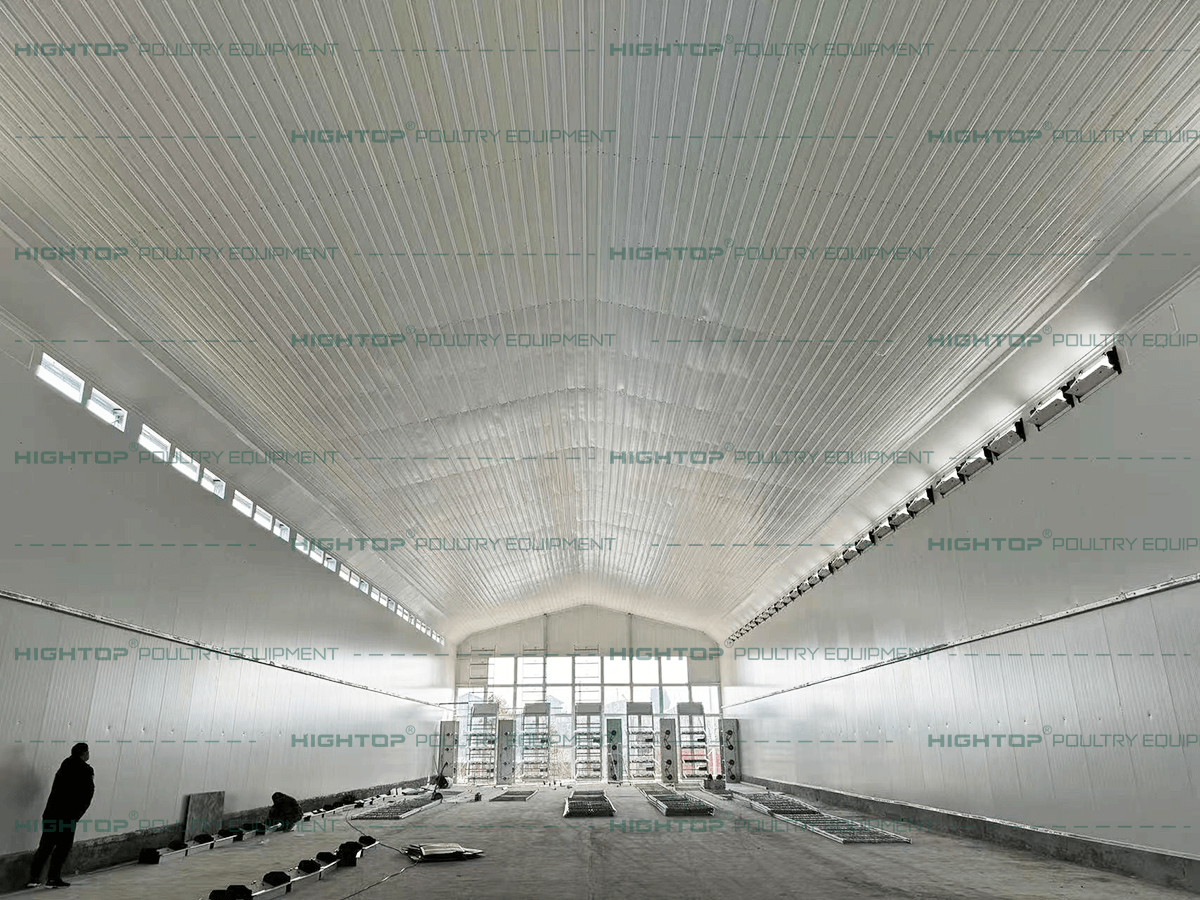

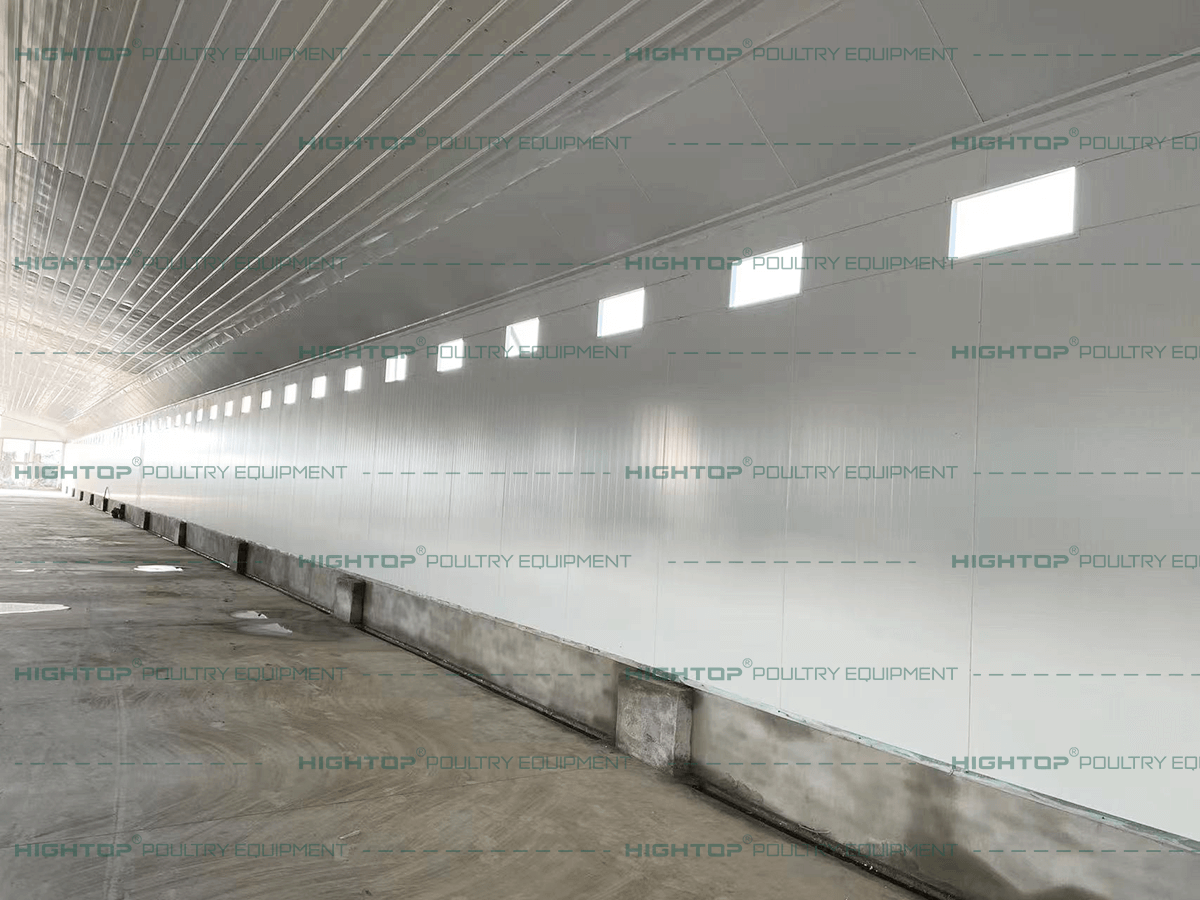

Enclosed chicken house

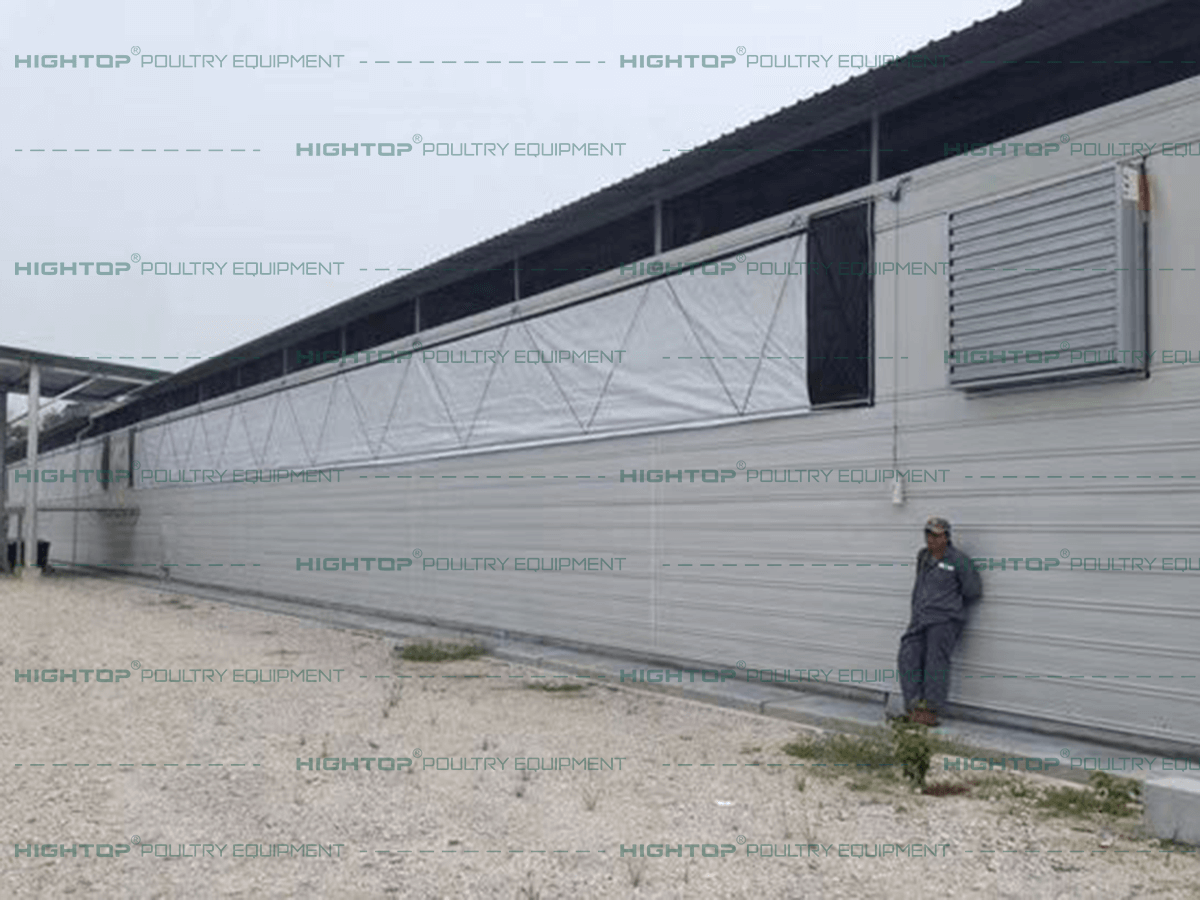

Semi-enclosed chicken house

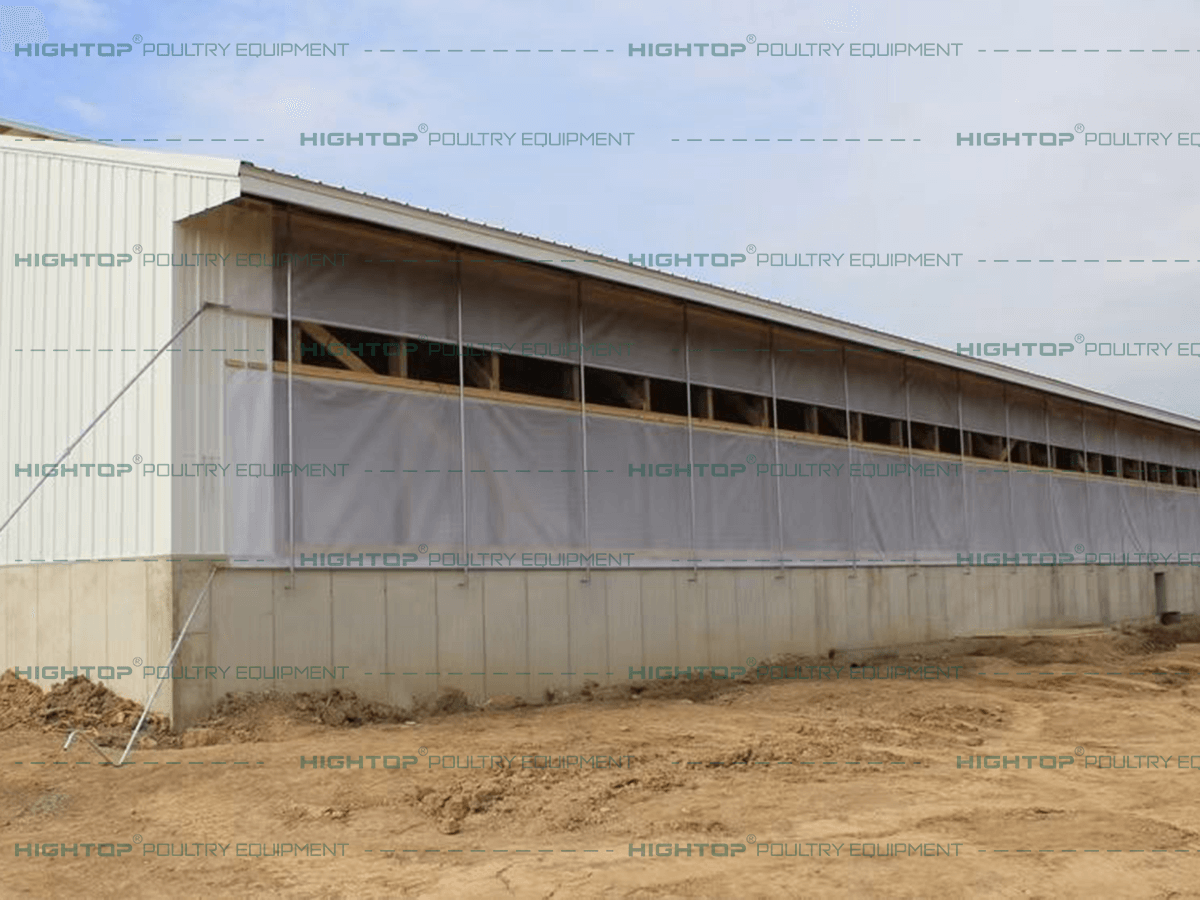

Open-style chicken house

2. Selection of Steel Structure Frame

Different countries may choose different steel structure frames based on their different rain and snow conditions and customs. Common steel structure frames include C-shaped steel column, K-shap steel colum and I beam.

2.1 C-shaped steel column

- 275gsm Zn-Al-Mg surface treatment, providing corrosion resistance comparable to stainless steel.

- Lightweight steel design, using less steel and saving costs.

- Shipping volume is smallest, saving significant ocean freight and destination port charges.

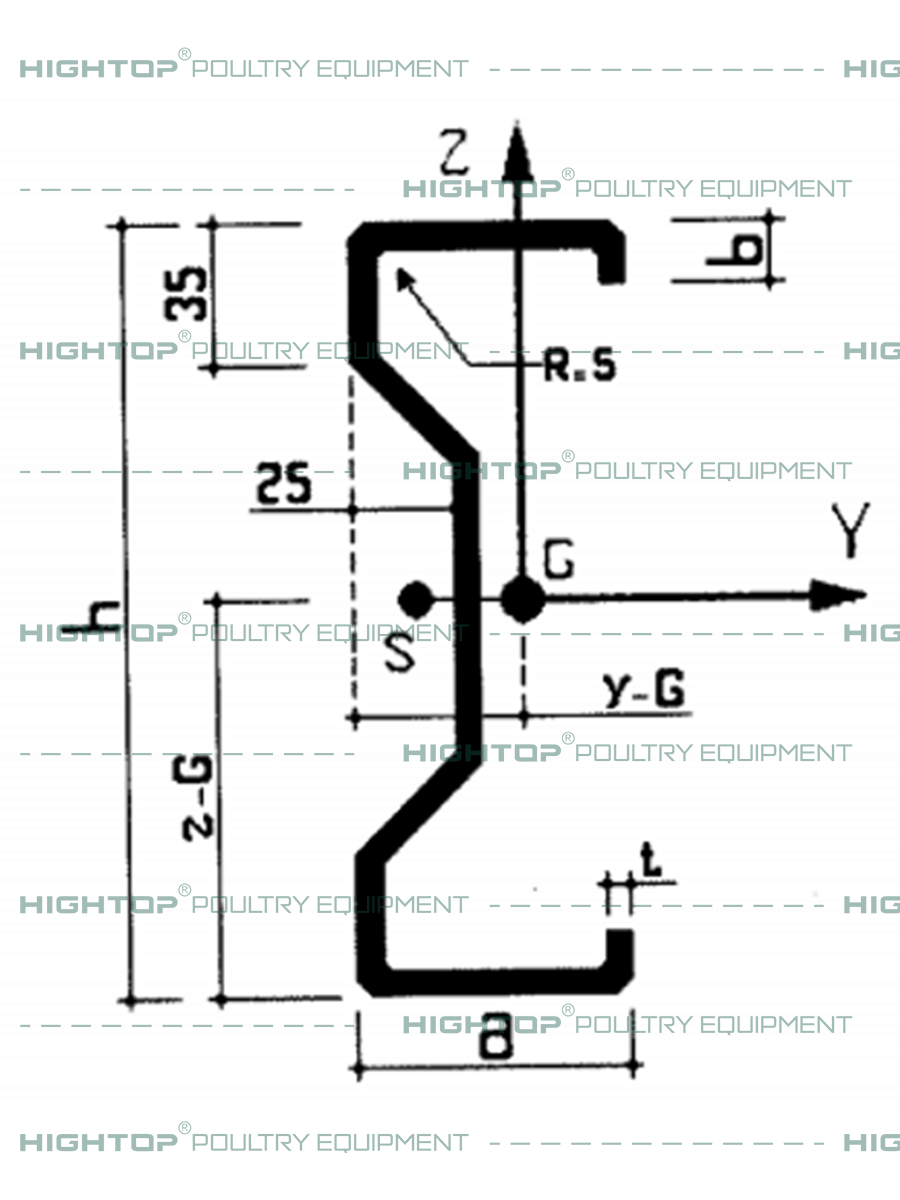

2.2 K-shaped steel column(Sigma cold-formed steel)

- 275gsm Zn-Al-Mg surface treatment, providing corrosion resistance comparable to stainless steel.

- Sigma cold-formed steel: higher load-bearing capacity and greater torsional stiffness.

- Lightweight steel design, using less steel and saving costs.s; smaller volume, saving on ocean freight and destination port charges.

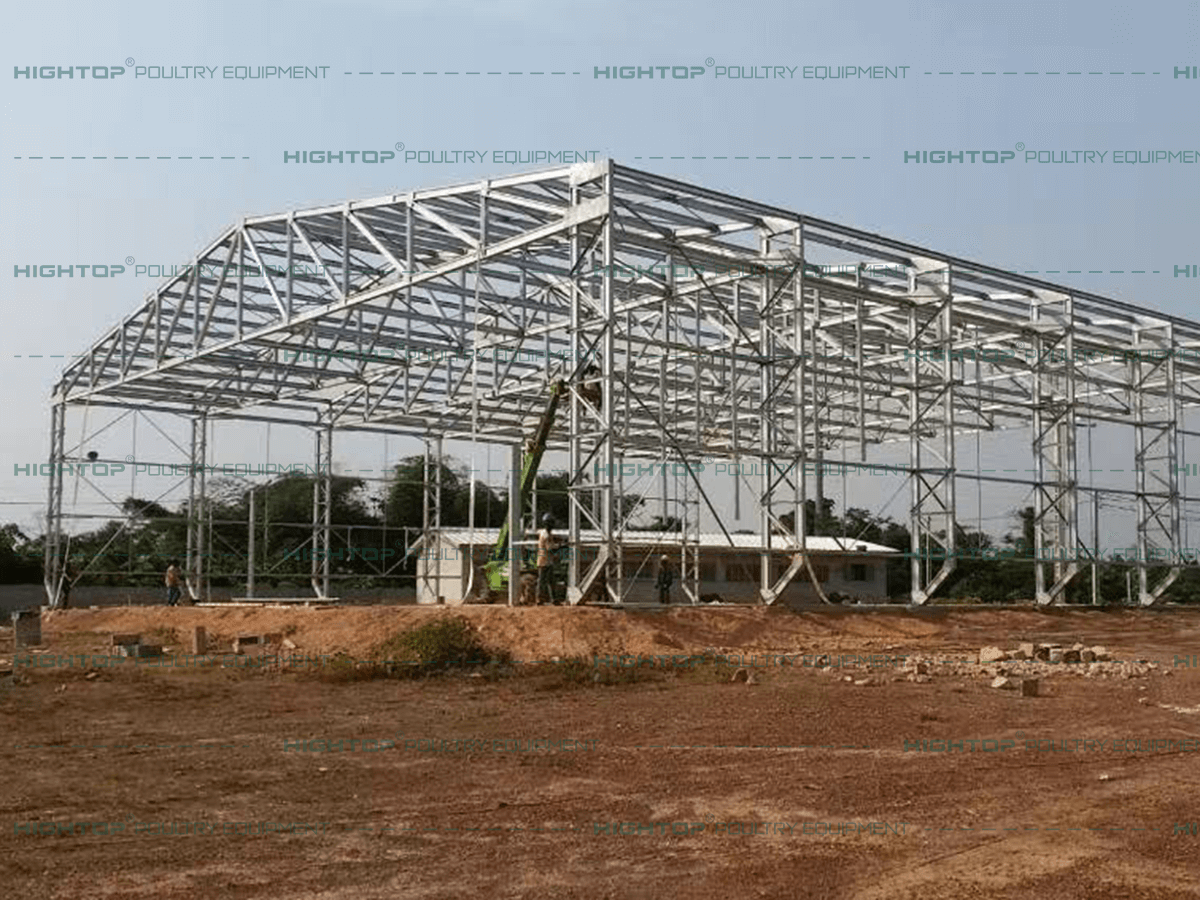

K-beams come in two types of chicken house structures: portal steel structures and truss structures. These two structures are designed to meet different wind and snow load requirements.

Portal steel structures use less material, but their resistance to wind and snow is not as high as that of truss structures.

2.3 I beam

- Traditional steel structure design, simple installation

- Two surface treatments available: painting and hot-dip galvanized

- Relatively large packing size

3. Selection of Fencing System

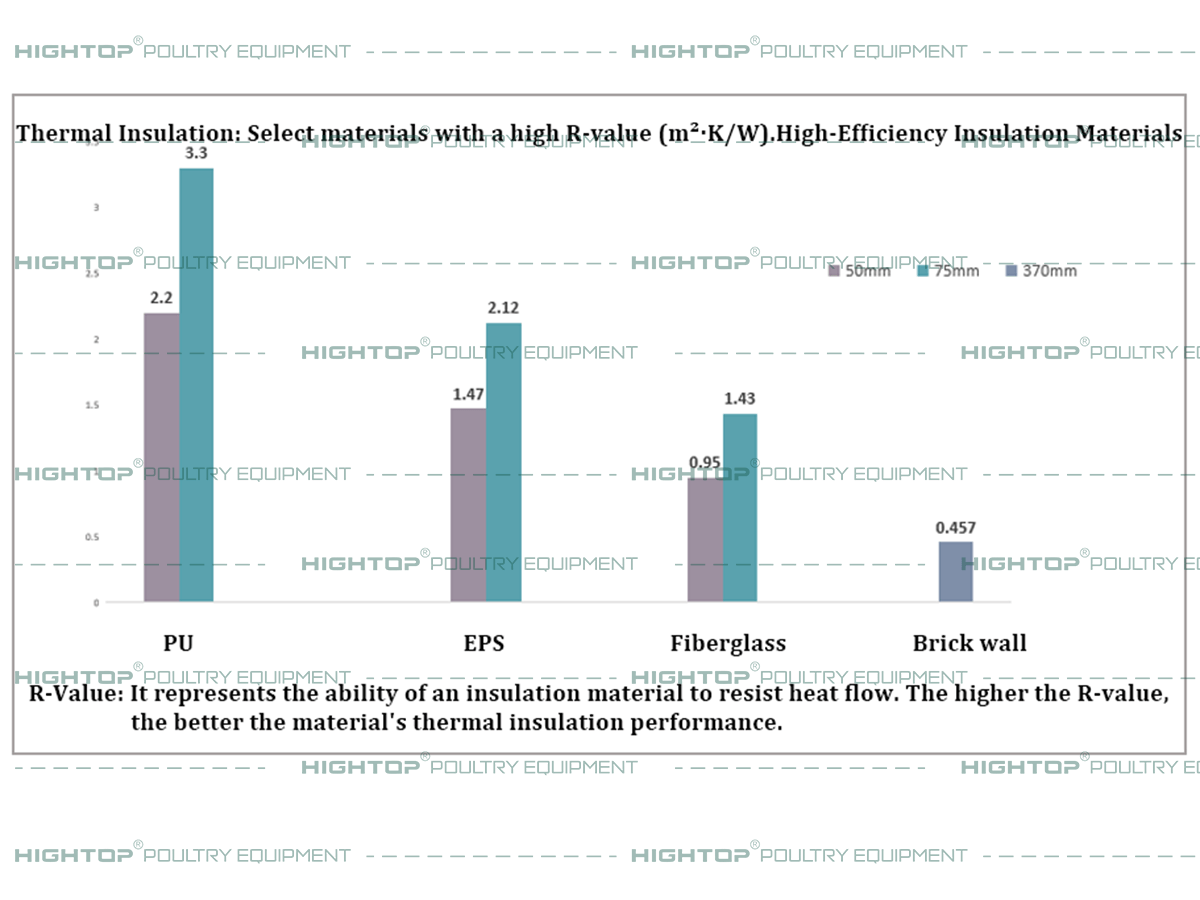

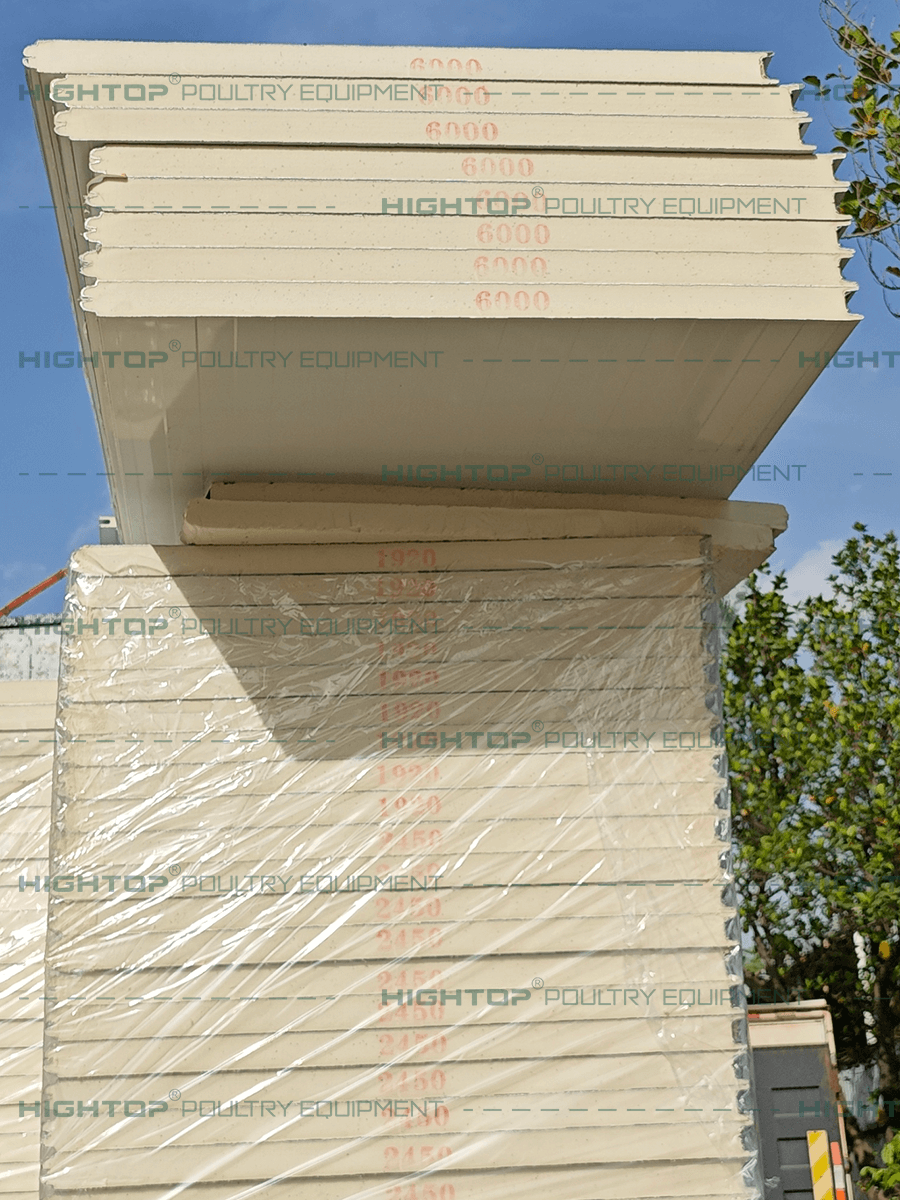

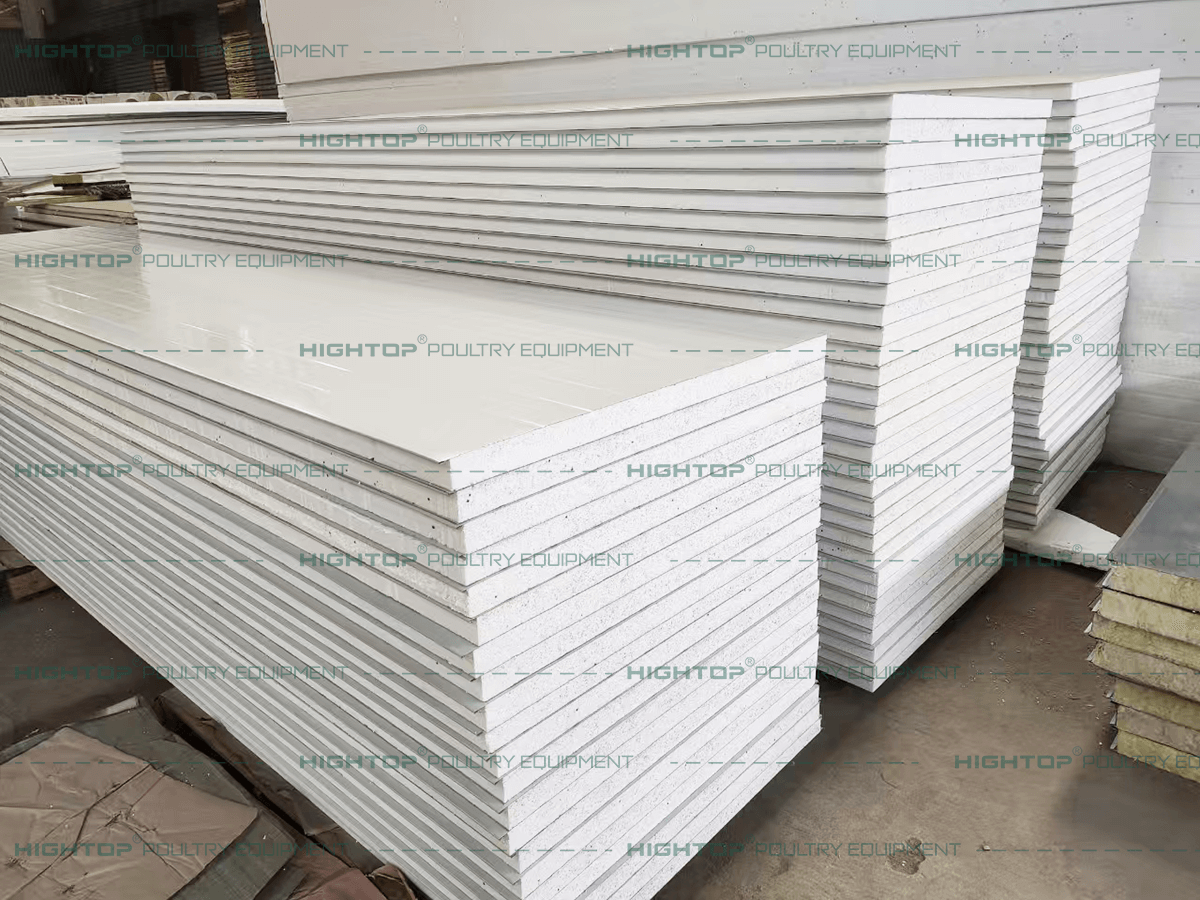

The enclosure system typically uses polyurethane boards(PU), polyethylene (EPS) board, glass wool, and brick walls. These four types offer different insulation effects.

Polyurethane has the best insulation properties; a 5cm polyurethane board even insulates better than a 37cm brick wall. For high-temperature and extremely cold regions, we recommend 5cm or 7.5cm polyurethane boards. In areas with suitable temperatures, polyethylene (EPS) boards can be chosen to save costs.

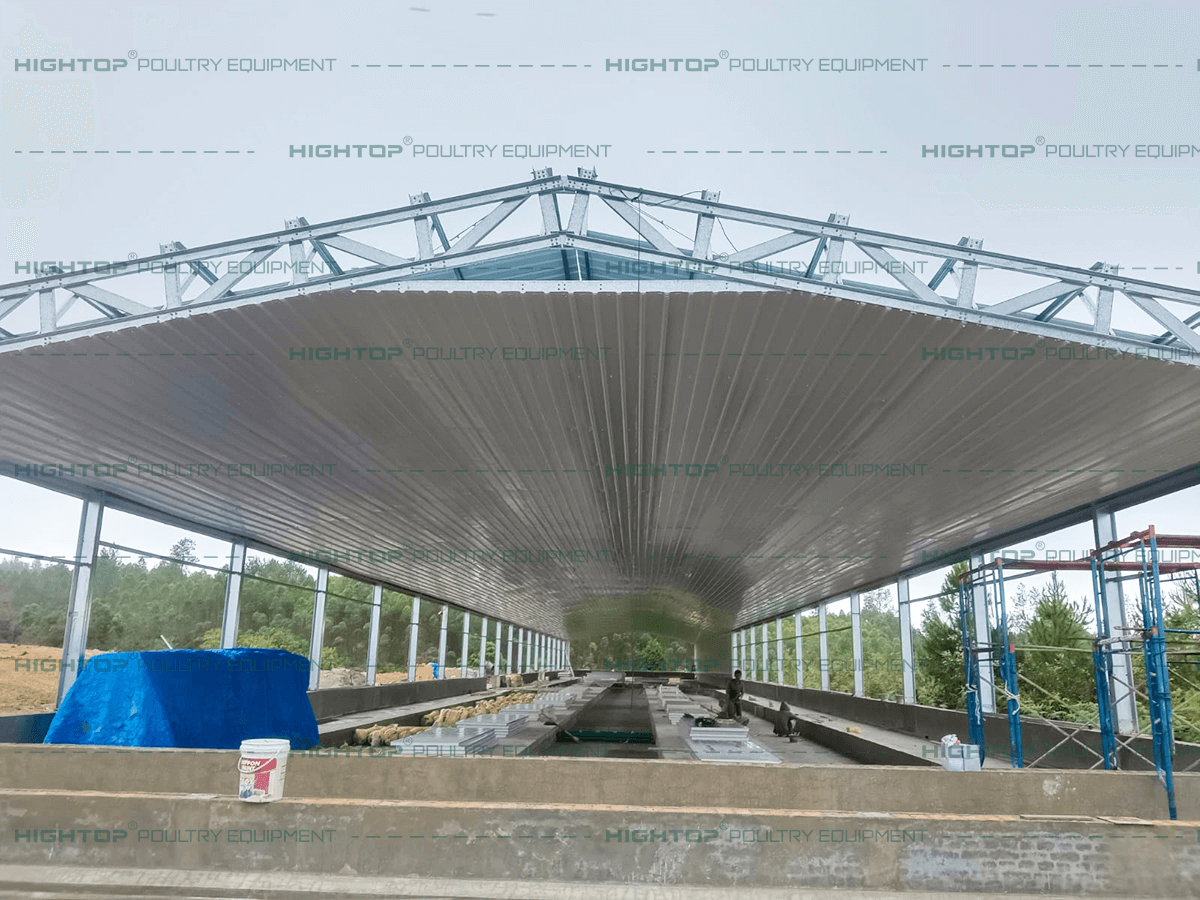

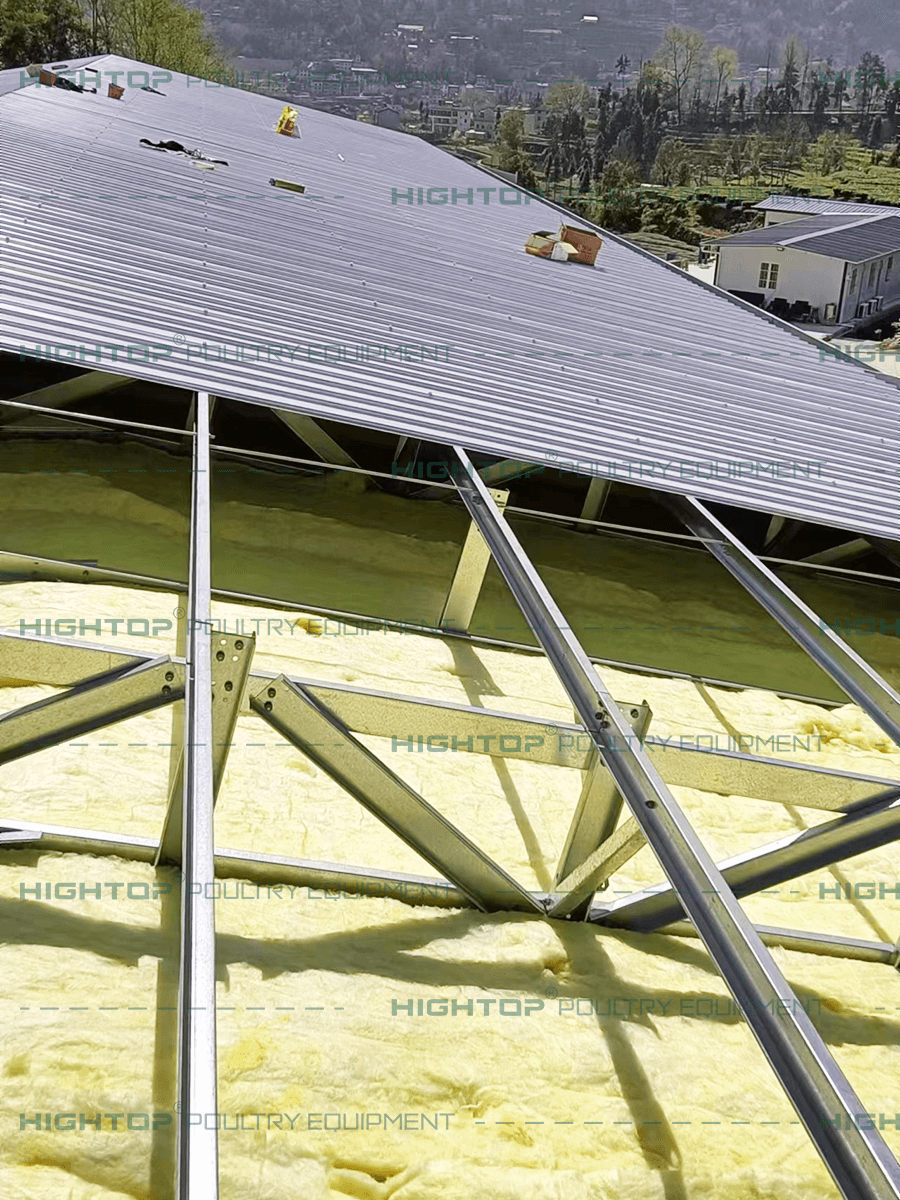

Regarding the roof, we recommend the following configuration, which is the most cost-effective option while ensuring thermal insulation performance.

The roof uses a single-layer panel + 15cm glass wool + suspended ceiling, which better isolates the outside air and provides good thermal insulation performance.

- Roof tiles: TCT0.5mm, 840 type, AZ100 galvanized steel, white-gray

- Insulation: 16kg density glass wool, 75mm thick, double-layered, with aluminum foil on one side.

- Ceiling tiles: TCT0.4mm, 900 type, AZ100 galvanized steel, white-gray

Of course, if your budget allows, you can also choose PU panels for the roof, which will have better insulation, but the price will be much higher.

4. Advantages of Hightop Chicken House Design

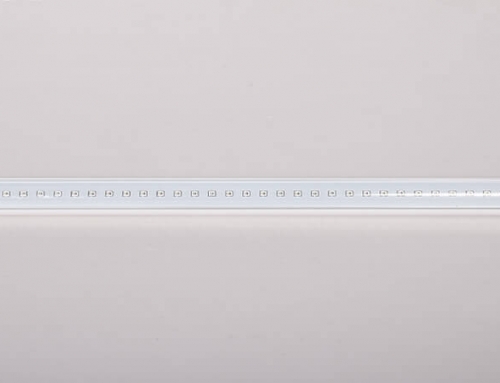

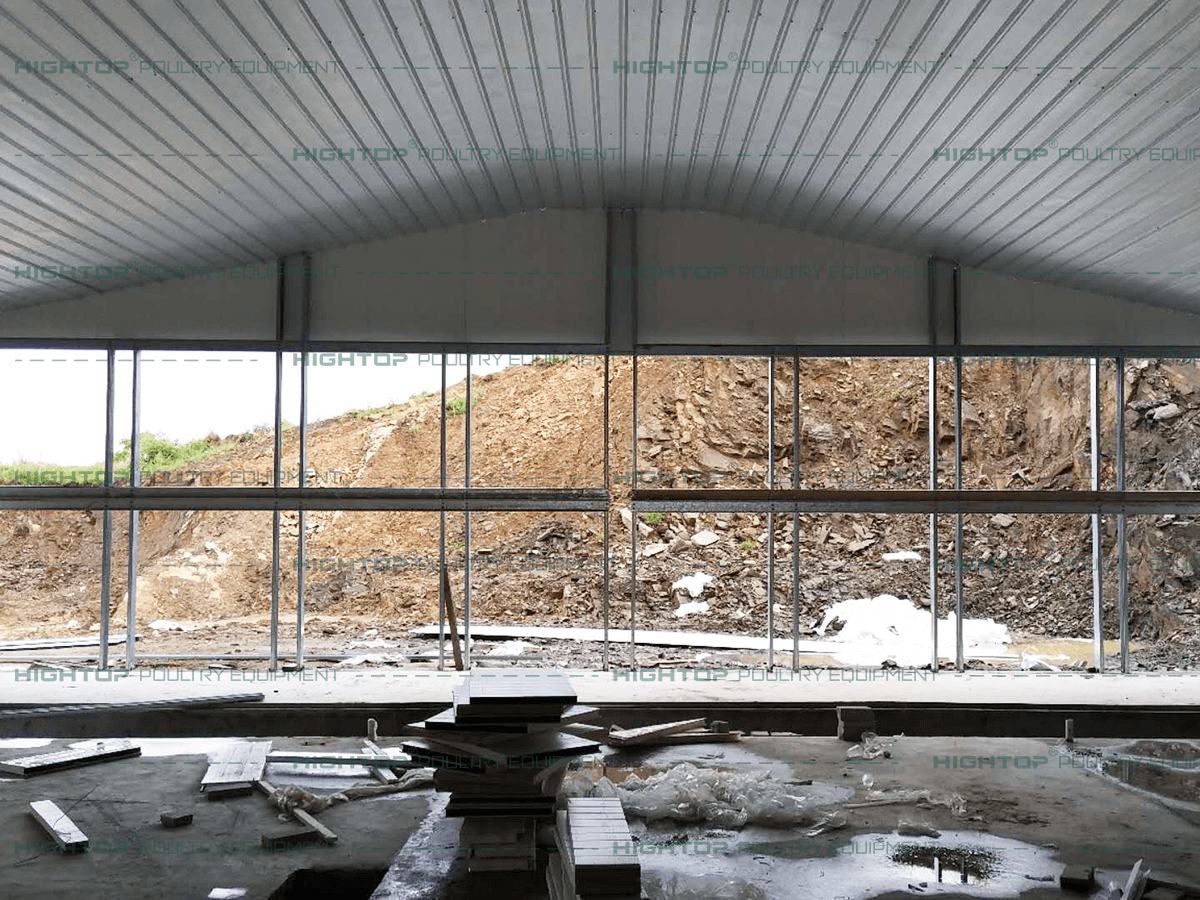

- The purlins are concealed by the suspended ceiling, resulting in a smooth roof and excellent ventilation.

- The interior is smooth, allowing for thorough cleaning, disinfection, and sterilization without leaving any blind spots.

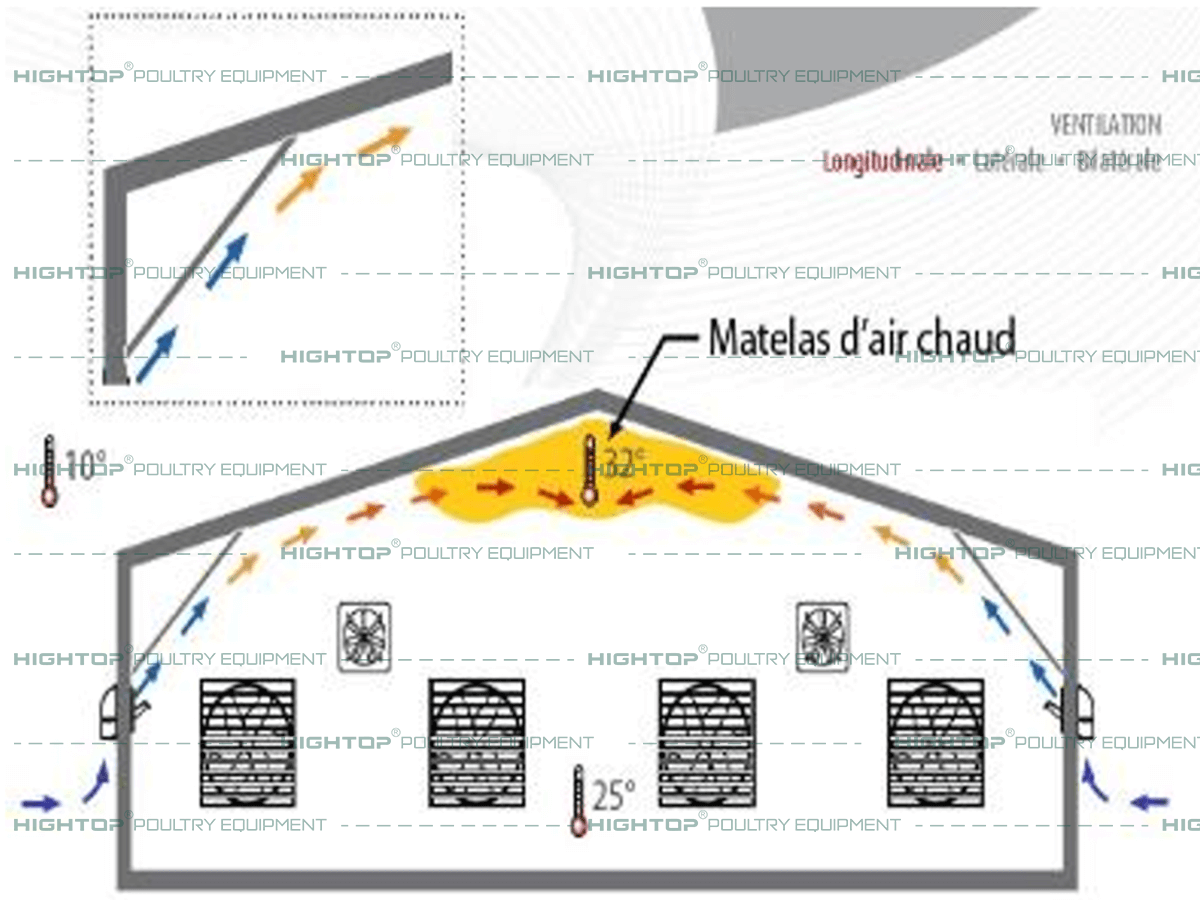

The wind can travel further along the walls, and the deflector design at the corners of the roof allows the wind to reach the center of the chicken coop, ensuring good ventilation.

The smoke test clearly showed that the wind had reached the center of the chicken house.