Case Study: Development of A Type Automated Layer Farm in Indonesia

Earlier this year, a poultry farmer from Indonesia contacted HIGHTOP Poultry Equipment with the goal of building a highly efficient and modern automated layer hen system to replace traditional manual farming. The customer wanted a system that could improve egg production, reduce labor dependency, and support long-term commercial operation. Based on the client’s capacity target and available land size, our engineering team developed a customized poultry house layout and complete automation plan suited to Indonesia’s climate and farming conditions.

Design Phase

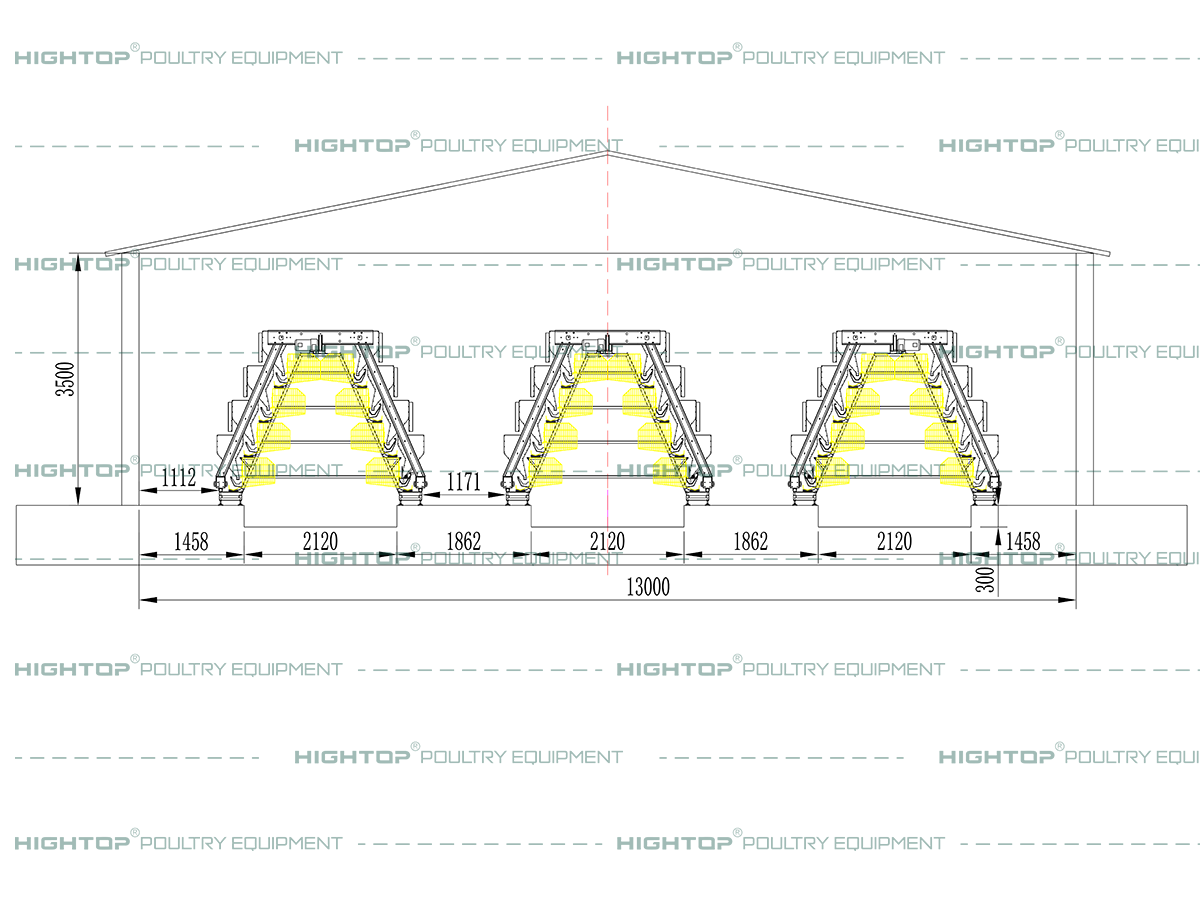

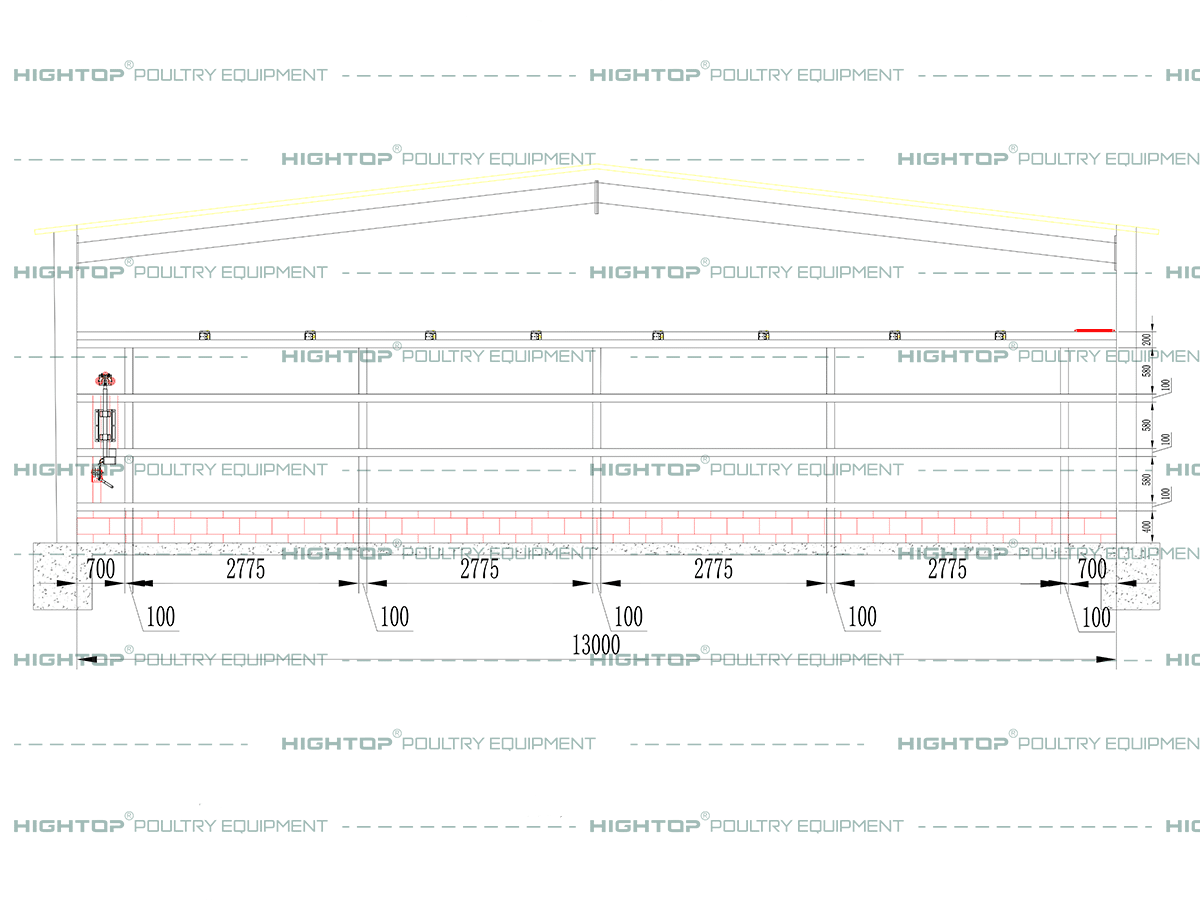

After thorough consultation and planning, the final poultry house layout and equipment specifications were confirmed as follows:

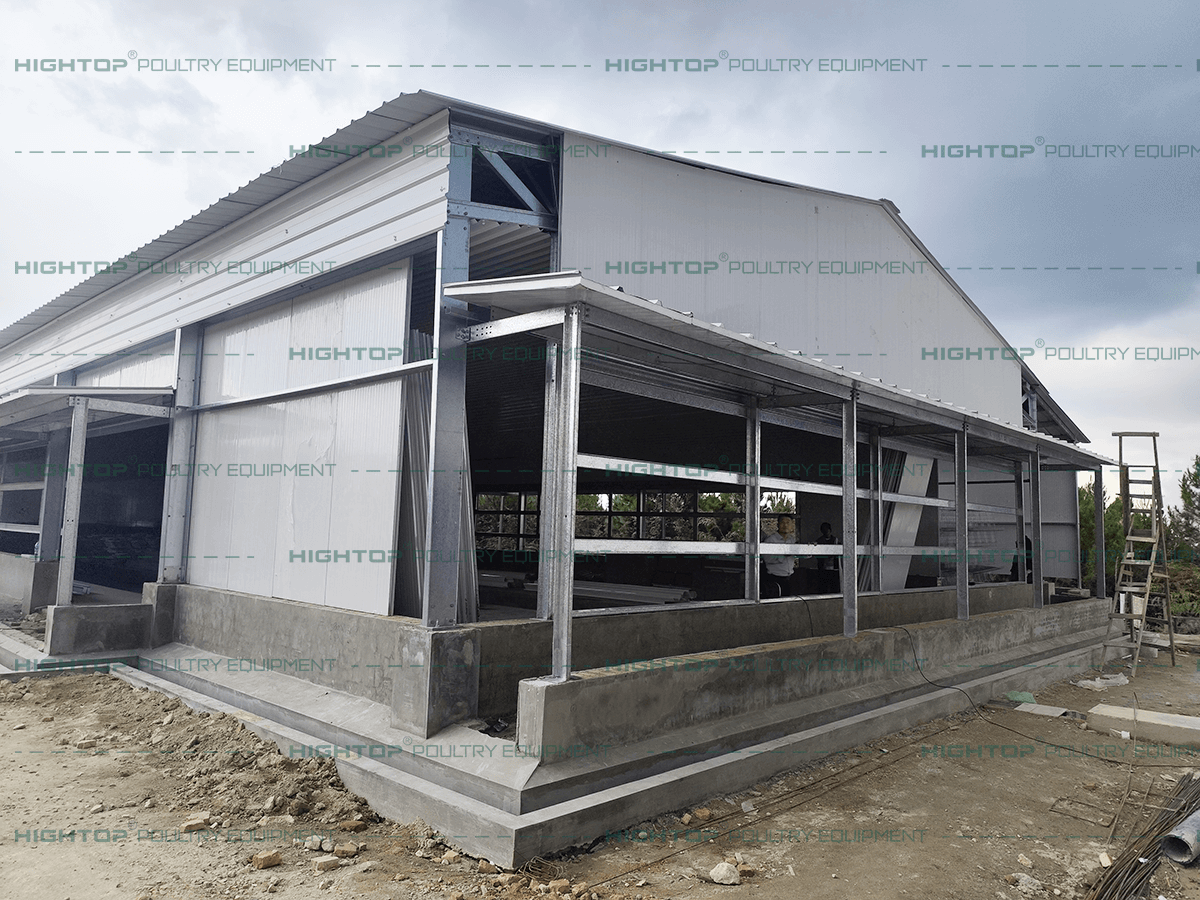

Poultry House Construction Design

-

Structure Type: Steel structure building

-

Frame Material: C-shaped galvanized steel beams

-

Wall Material: EPS sandwich panels for insulation

-

Roof Material: Glass wool insulated roof panels

-

Ceiling Type: Sloped ceiling to prevent moisture accumulation

Overall Dimensions:

92 meters (length) × 13 meters (width) × 3.5 meters (height)

This structure was selected for its durability, resistance to corrosion in humid environments, and strong heat-insulation performance — an important factor in tropical regions with fluctuating temperatures and high humidity levels.

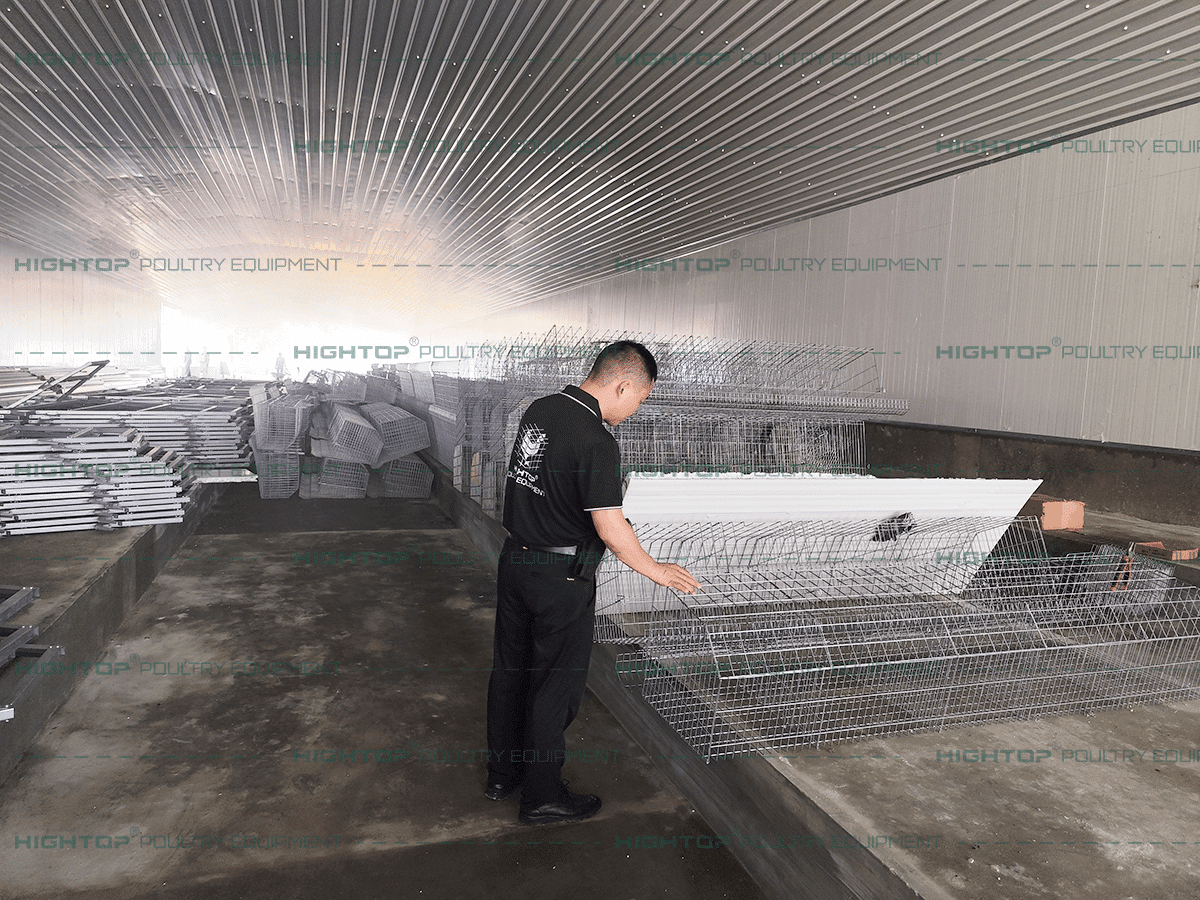

Layer Cage System Specifications

The heart of the project is HIGHTOP’s Type A automated layer hen cage system. Final design details include:

| Specification | Data |

|---|---|

| Cage Type | Type A (automatic) |

| Cage Size | 1.95 m × 0.45 m × 0.41 m |

| Number of Tiers | 4 |

| Number of Rows | 3 |

| Cages Per Row | 42 |

| Birds Per Cage | 160 |

| Total Capacity | 20,160 hens |

| Space Per Hen | 438 cm² |

This stocking density meets industry standards while ensuring comfort, proper behavior expression, and excellent production efficiency.

Production Phase

Once the design was finalized, HIGHTOP began the manufacturing process using precision equipment. Production included:

-

Automated cutting and forming

-

Smooth surface welding

-

Hot-dip galvanizing

-

Rust and wear resistance testing

Each cage went through strict inspection to ensure proper spacing, safe wire surface contact areas, and structural stability. The hot-dip galvanizing treatment ensures a corrosion-resistant lifespan of 15–20 years under appropriate operation and cleaning.

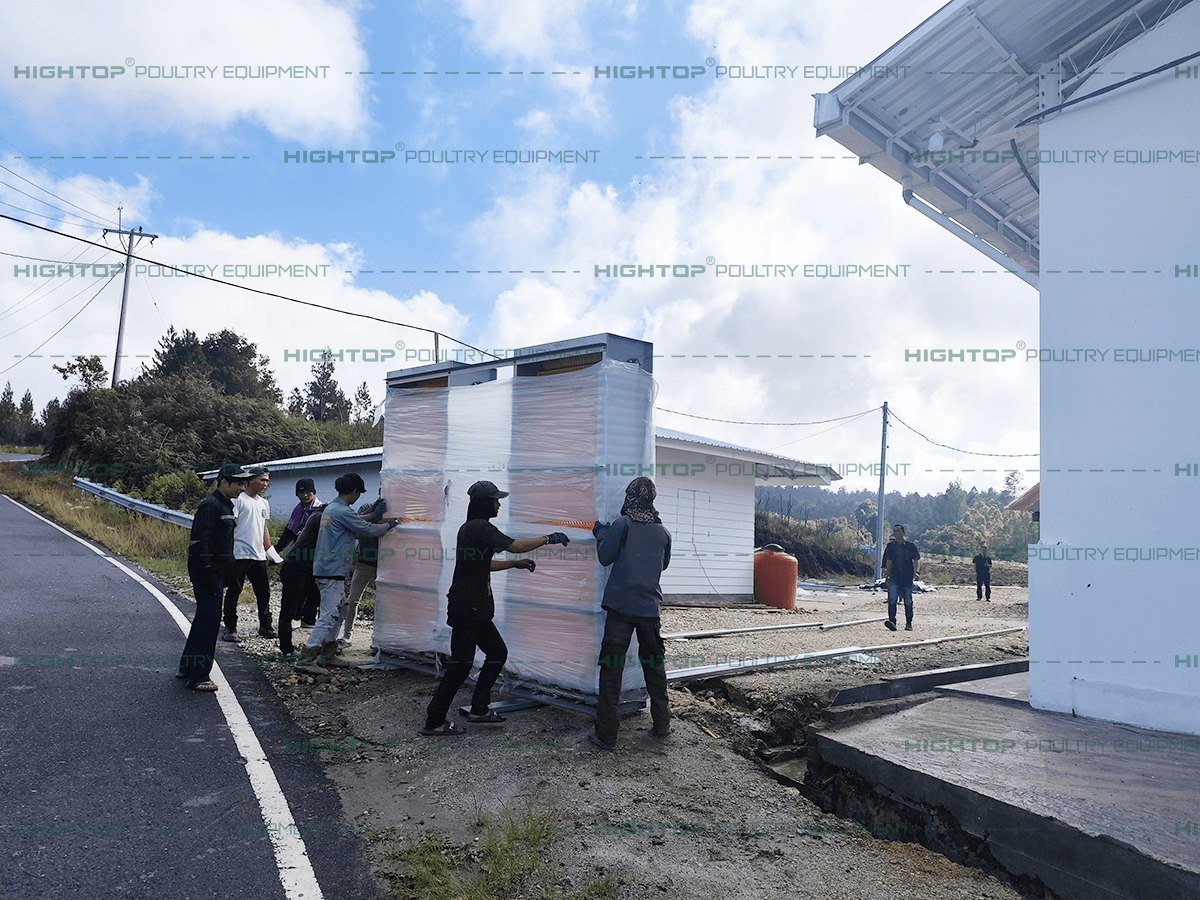

Transportation and Logistics

All equipment components were packaged with protective wrapping, clear labels, and placement diagrams. The shipments were divided into phases to support efficient on-site storage and installation progress. The cargo was transported by sea using reinforced container packing methods to avoid deformation or rough handling damage.

Upon arrival in Indonesia, the client received a full shipment inventory list, layout plan, and assembly instructions to ensure smooth on-site execution.

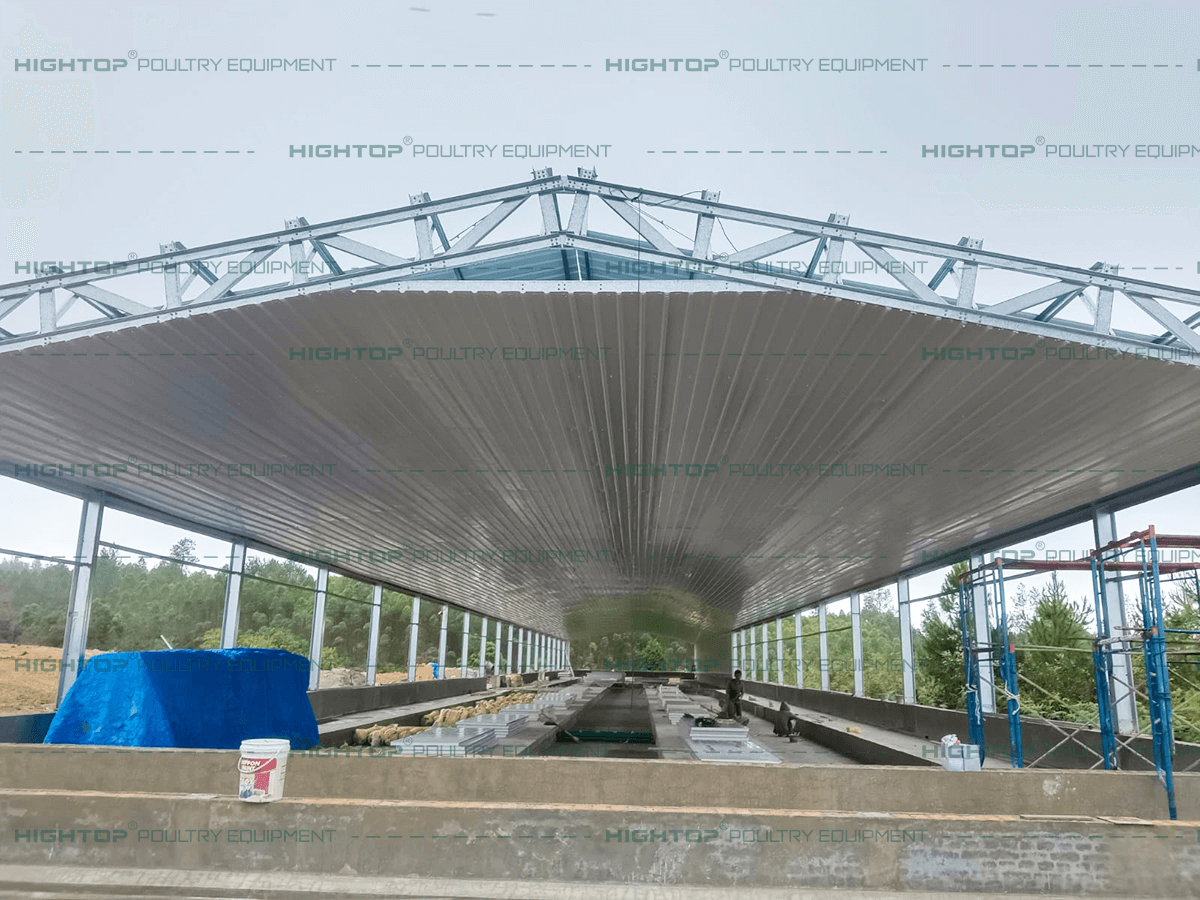

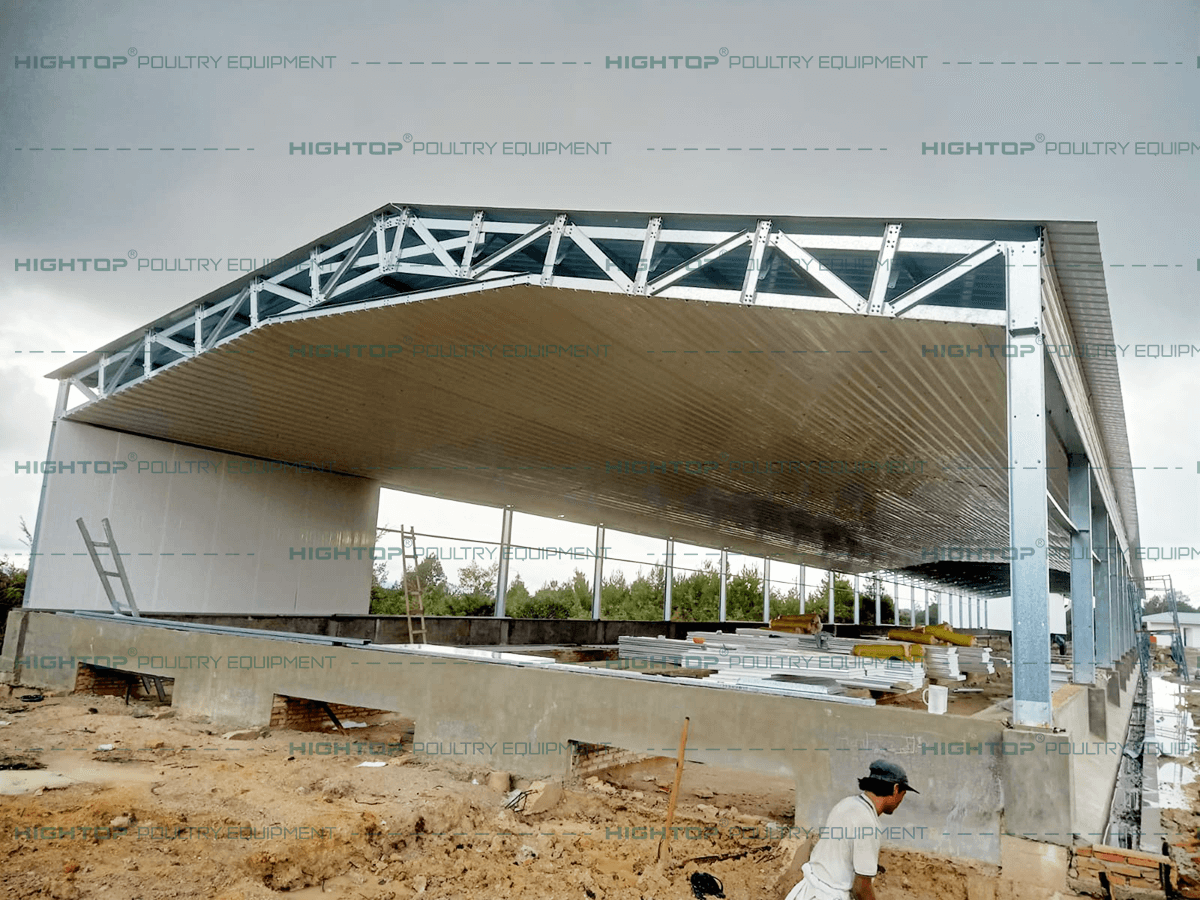

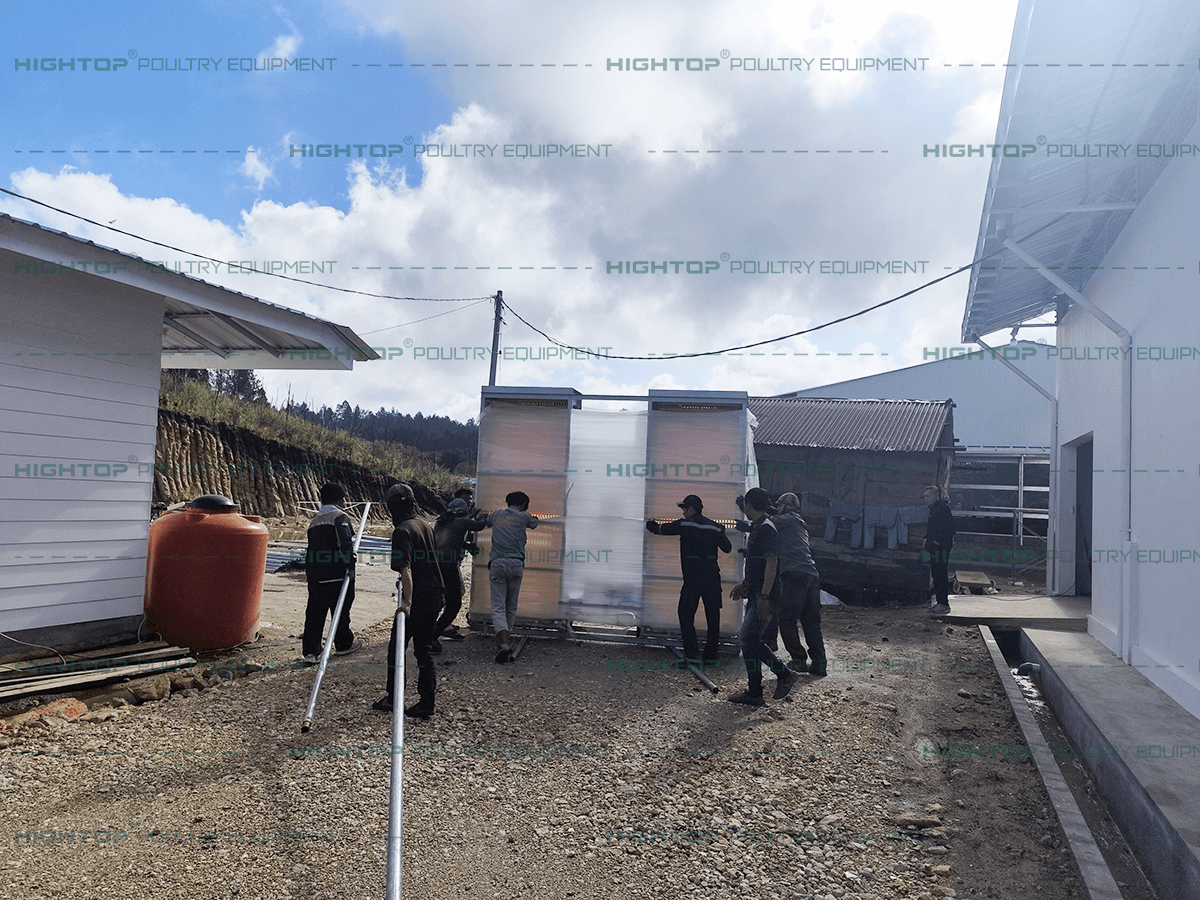

Installation Phase

After delivery, HIGHTOP assigned trained technicians to guide installation both remotely and on-site. Installation included the following steps:

-

Steel house frame assembly

-

Cage placement and alignment

-

Automatic feeding line installation

-

Automatic nipple drinker line calibration

-

Manure removal conveyor belt installation

-

Electrical system and automation controller setup

Special attention was given to the alignment of manure belts and egg-collection slopes to ensure smooth operation with no feed waste, water leakage, or belt friction.

System Debugging and Staff Training

Before loading chickens, all systems underwent full testing, including:

-

Feed conveyor calibration

-

Water pressure regulation

-

Manure belt synchronization

-

Egg-collection flow testing

-

Emergency stop system simulation

To ensure seamless operation, we also provided comprehensive training covering:

-

Equipment operation and controls

-

Feeding and watering monitoring

-

Daily cleaning and preventive maintenance

-

Troubleshooting and spare-part handling

This ensured the farm team was fully independent and confident in running an automated system.

Hicken Loading and Farm Operation

Once commissioning was complete, the client introduced 20,160 layer hens into the facility. The flock adapted quickly to the new environment. Observations during the first weeks included:

-

Smooth and consistent feed and water consumption

-

Low stress indicators and stable flock behavior

-

Efficient manure removal with significantly reduced odor

-

Low feed waste due to anti-spill trough design

-

Egg collection efficiency significantly higher than manual systems

The client reported that automation reduced the workforce requirement from 10 workers to only 3, lowering labor cost while improving operational precision and hygiene.

Client Feedback

Within the first two months of operation, egg production rates gradually increased. The customer observed:

-

Higher uniformity in hen body weight

-

Improved shell quality due to controlled environment

-

Cleaner eggs because of proper slope angle and hygienic collection

-

Reduced maintenance and manual workload

The customer expressed strong satisfaction with both the production results and the equipment quality.

Advantages of the HIGHTOP Type A Automated Layer Cage System

High Production Efficiency

Automated feeding, watering, egg collection, and manure removal ensure a consistent environment that leads to higher egg output.

Labor Reduction

Automation dramatically decreases manual workload, improving operational scalability.

Strong Durability and Long Lifespan

Hot-dip galvanized steel ensures excellent corrosion resistance, ideal for humid tropical climates.

Cost-Effective Operational Management

Controlled feed distribution, clean manure handling, and reduced disease risk improve overall farm profitability.

Animal Welfare and Comfort

Proper spacing, ventilation, and stable feed supply support healthy growth and better laying performance.

This Indonesia-based project demonstrates how modern automation technology, thoughtful design, and strong engineering support can significantly improve poultry farming profitability. From initial design to installation, debugging, and operation, HIGHTOP Poultry Equipment ensured a seamless process and a reliable long-term farming solution.

Today, the system is running efficiently, delivering strong production results and helping the client transition successfully from traditional manual poultry farming to modern automated operations.