Case Study: Rebuilding Trust and Delivering a Complete H-Type Automated Layer Farm Solution in the Philippines

1. Project Background: Challenges Faced Before Choosing a New Supplier

This project involves a commercial layer farm in the Philippines planning to expand its production capacity through the construction of a modern steel-structure chicken house equipped with an automated layer cage system. However, before partnering with HIGHTOP Poultry Equipment, the client had experienced significant challenges that made them extremely cautious when selecting a new supplier.

In a previous project, the client had purchased poultry equipment from a certain supplier through a local agent. Although the equipment itself appeared acceptable at the time of purchase, serious problems arose after delivery. The agent failed to provide installation guidance, commissioning support, or effective after-sales service. As a result, the farm encountered operational inefficiencies, delayed commissioning, and unresolved technical issues, all of which negatively impacted production performance and increased operational risk.

This experience caused the client to lose confidence in suppliers who focused only on selling equipment without providing full project support. When planning the new farm, the client clearly stated that trust, service capability, and long-term technical support were more important than price alone. Their core concerns included:

-

Reliable installation support

-

Professional technical guidance during commissioning

-

Long-term after-sales service

-

A supplier capable of delivering a complete, integrated solution

2. How HIGHTOP Poultry Equipment Addressed the Client’s Concerns

Understanding the client’s past experience and concerns, HIGHTOP Poultry Equipment adopted a trust-oriented and transparent approach rather than a traditional sales-driven model.

The relationship began with multiple meetings at international poultry exhibitions, where the HIGHTOP Poultry Equipment team introduced its automated layer cage systems, steel structure chicken houses, and supporting equipment in detail. These discussions went beyond product specifications and focused on real-world operation, system integration, installation procedures, and service assurance.

After the exhibitions, HIGHTOP Poultry Equipment arranged additional independent meetings to further explain system layouts, automation logic, and project timelines. To strengthen trust, the client was also invited to conduct two on-site farm visits to operating projects using HIGHTOP Poultry Equipment solutions. During these visits, the client was able to:

-

Observe the performance of H-type layer cage systems in operation

-

Speak directly with existing farm owners

-

Evaluate build quality and automation stability

-

Understand how installation and after-sales service were delivered in practice

Most importantly, HIGHTOP Poultry Equipment clearly explained its local service capability in the Philippines. The company works with a cooperative installation team in the Philippines and can dispatch professional technicians to provide on-site installation guidance when required. In addition, HIGHTOP Poultry Equipment committed to providing post-installation follow-up visits and long-term technical support, ensuring that any operational issues would be addressed promptly.

This comprehensive and transparent approach gradually rebuilt the client’s confidence and led to the successful confirmation of the project.

3. Project Overview and Technical Specifications

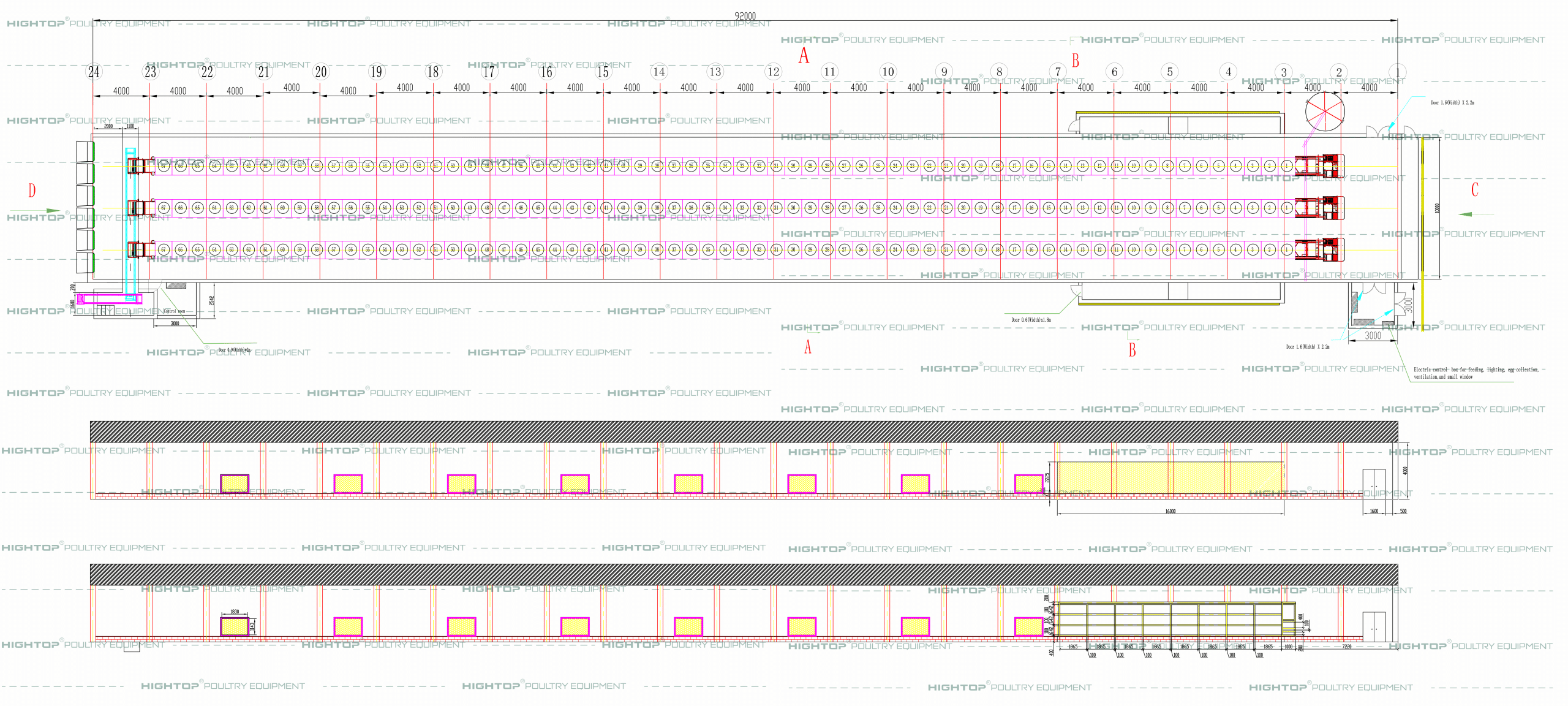

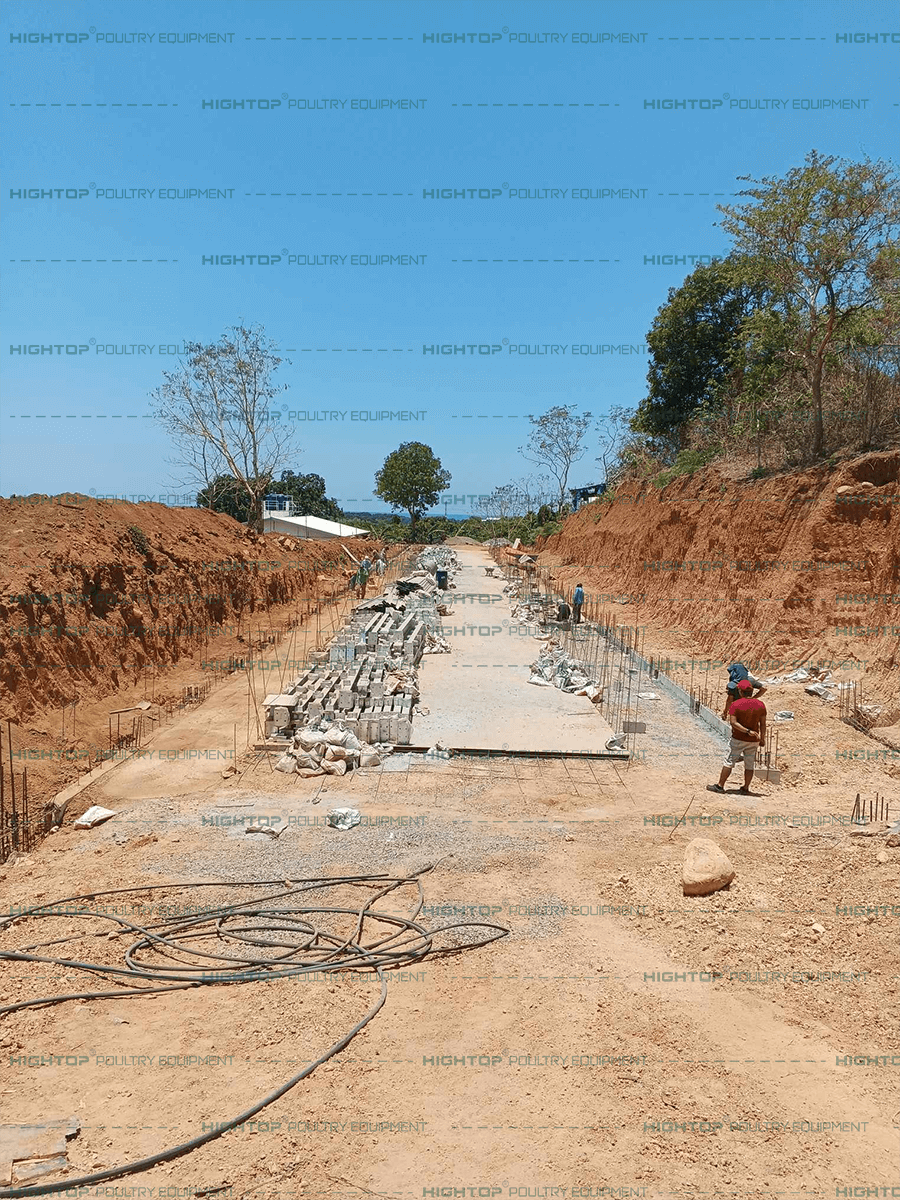

After final approval, the client entrusted HIGHTOP Poultry Equipment with the supply of both the steel structure chicken house and the H-type automatic layer cage system with a central egg collection line.

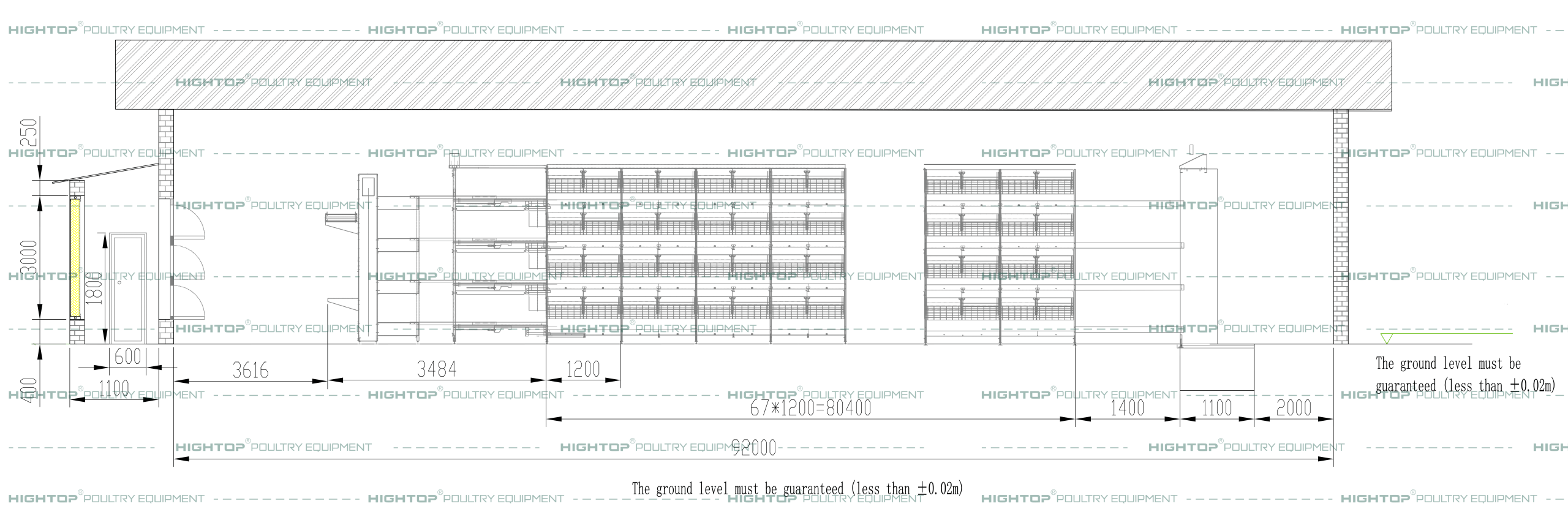

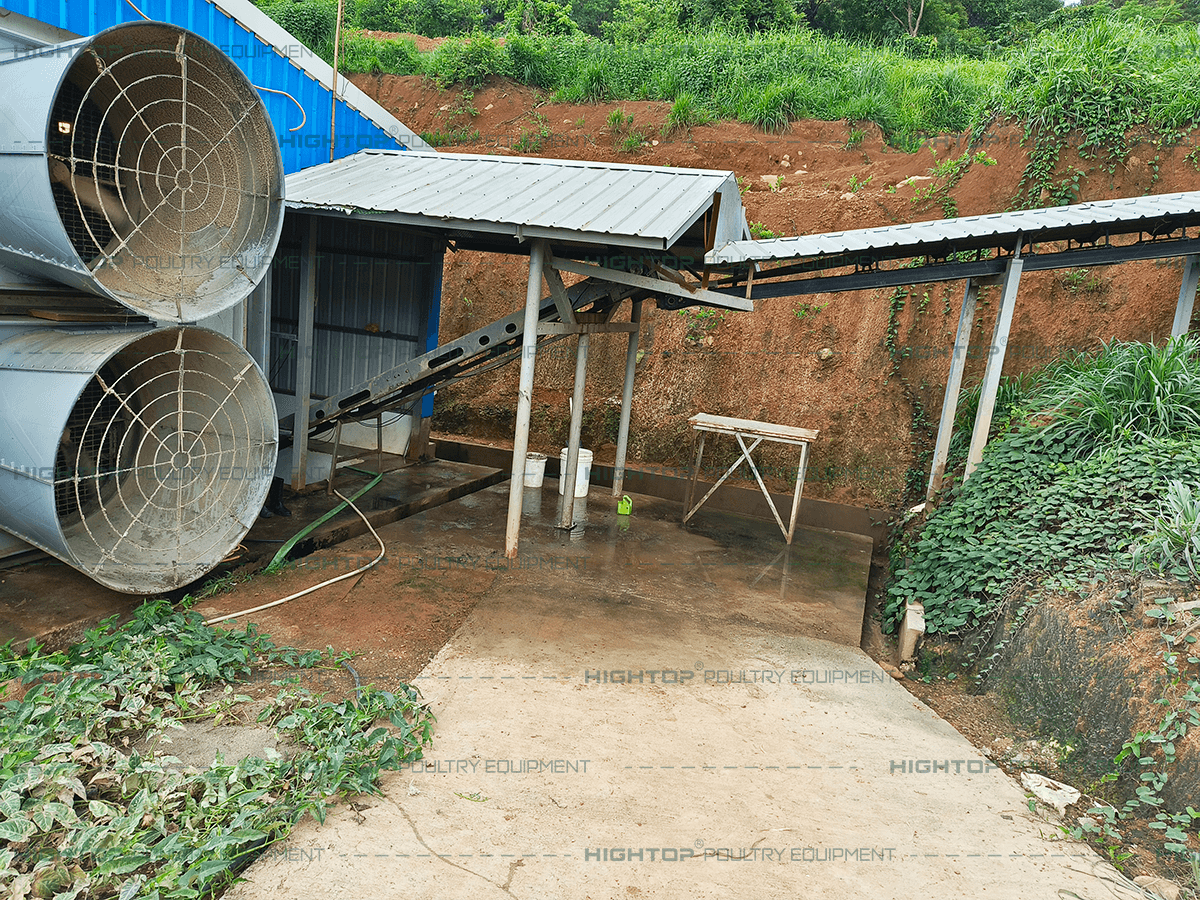

Chicken House Specifications

-

Dimensions: 92 meters (length) × 10 meters (width) × 4 meters (height)

-

Structure: Steel structure chicken house designed for intensive layer farming

-

Layout: Optimized for ventilation, lighting, and automated management

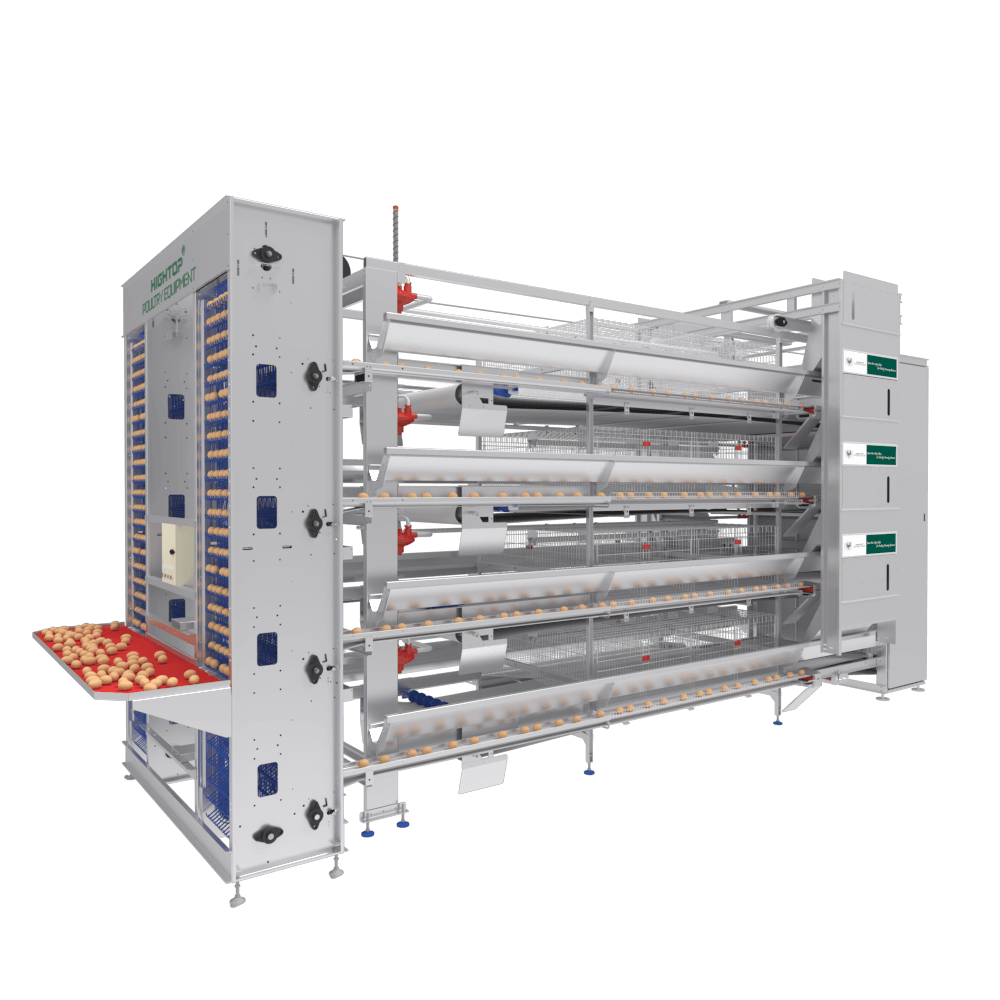

Layer Cage Configuration

-

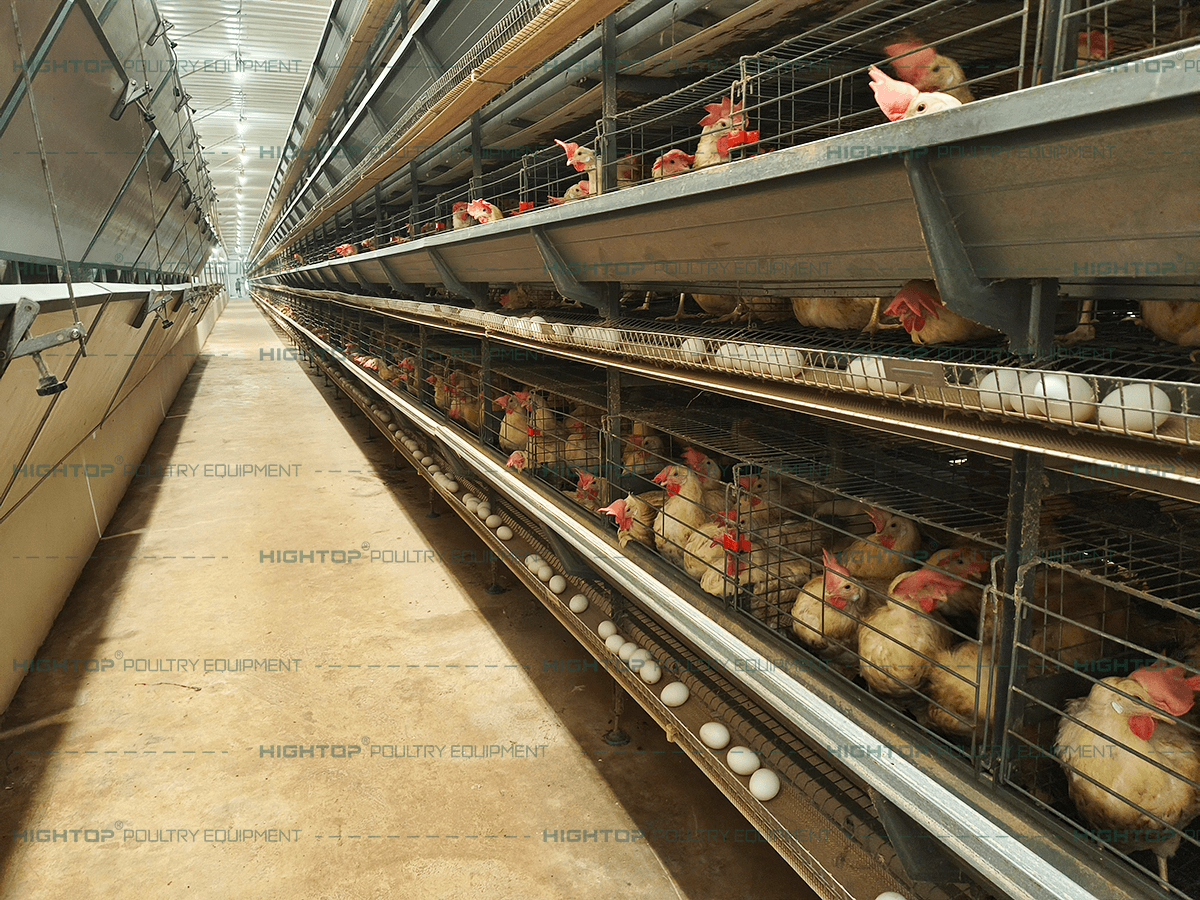

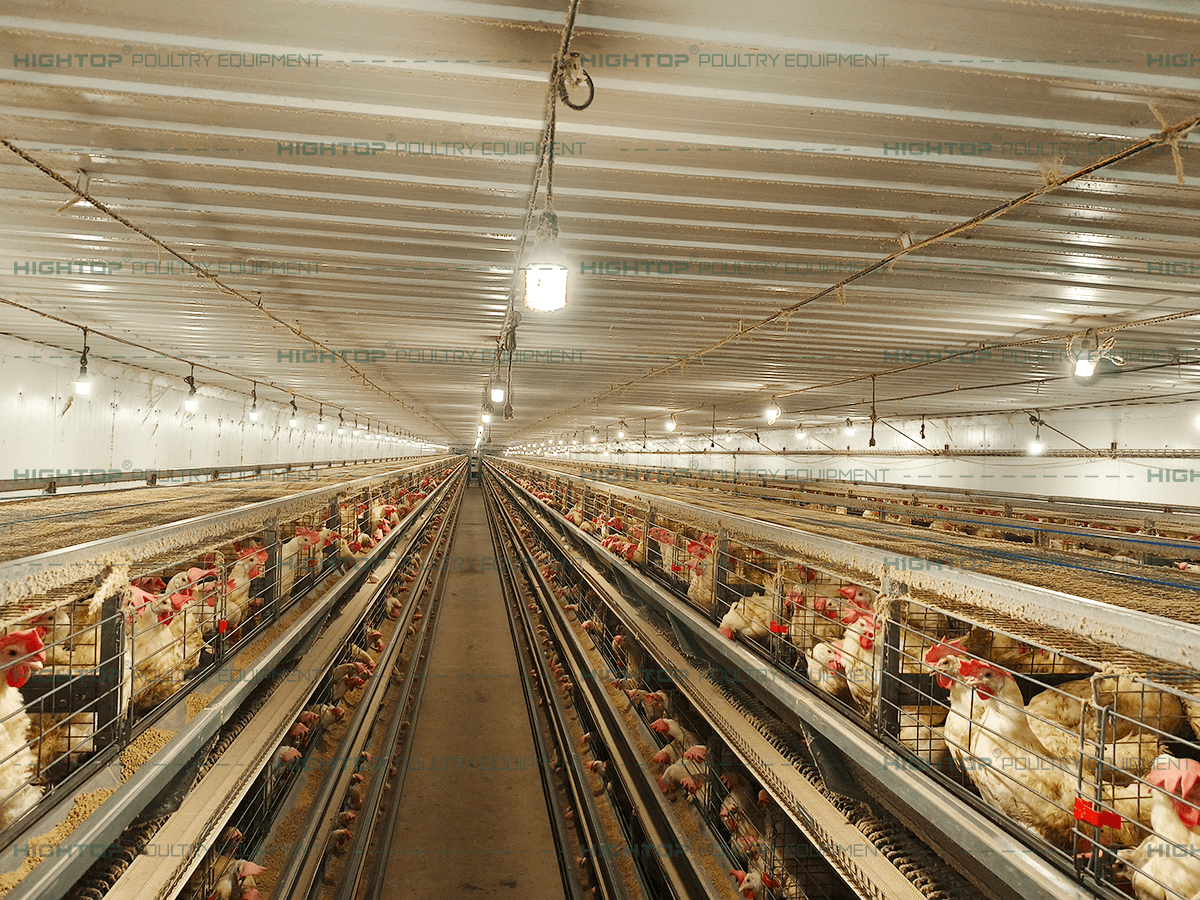

Cage Type: 4-tier H-type automatic layer cages

-

Layout: 3 rows, 67 cage sets per row

-

Total Cage Sets: 201 sets

-

Cage Capacity: Designed to meet commercial stocking standards

-

Total Number of Chickens: 25,728 layers

This configuration allows high stocking density while maintaining efficient management, good ventilation, and stable production performance.

4. Central Egg Collection Line and Egg Grading System

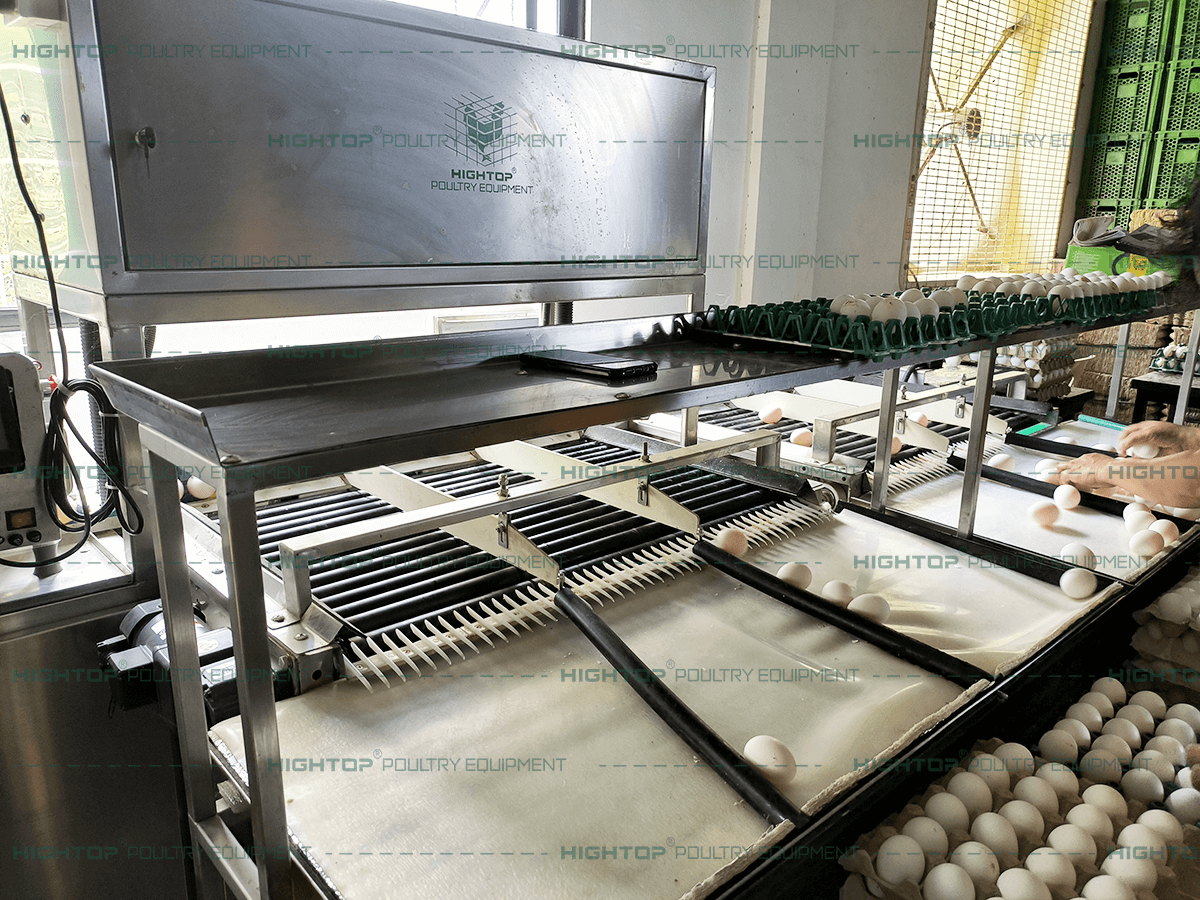

A key feature of this project is the integration of HIGHTOP Poultry Equipment’s central egg collection line, which plays a critical role in improving efficiency and egg quality management.

The central egg collection line is designed to transport eggs directly from inside the chicken house to the egg storage and processing area. Instead of manual collection or decentralized handling, eggs from all cage rows are conveyed in a synchronized and controlled manner, significantly reducing labor intensity and egg breakage.

At the end of the central egg collection line, this project is equipped with an egg grading machine, which further enhances the value of the system. The egg grading machine performs multiple functions, including:

-

Automatic egg inspection

-

Egg surface cleaning

-

Weight-based grading

-

Sorting eggs into uniform categories

By integrating egg grading directly into the production line, the farm is able to standardize egg quality, improve packaging efficiency, and better meet market requirements. This system also reduces human contact with eggs, improving hygiene and food safety standards.

The use of both a central egg collection line and an egg grading machine transforms egg handling from a labor-intensive process into a streamlined, automated workflow, significantly increasing overall farm efficiency.

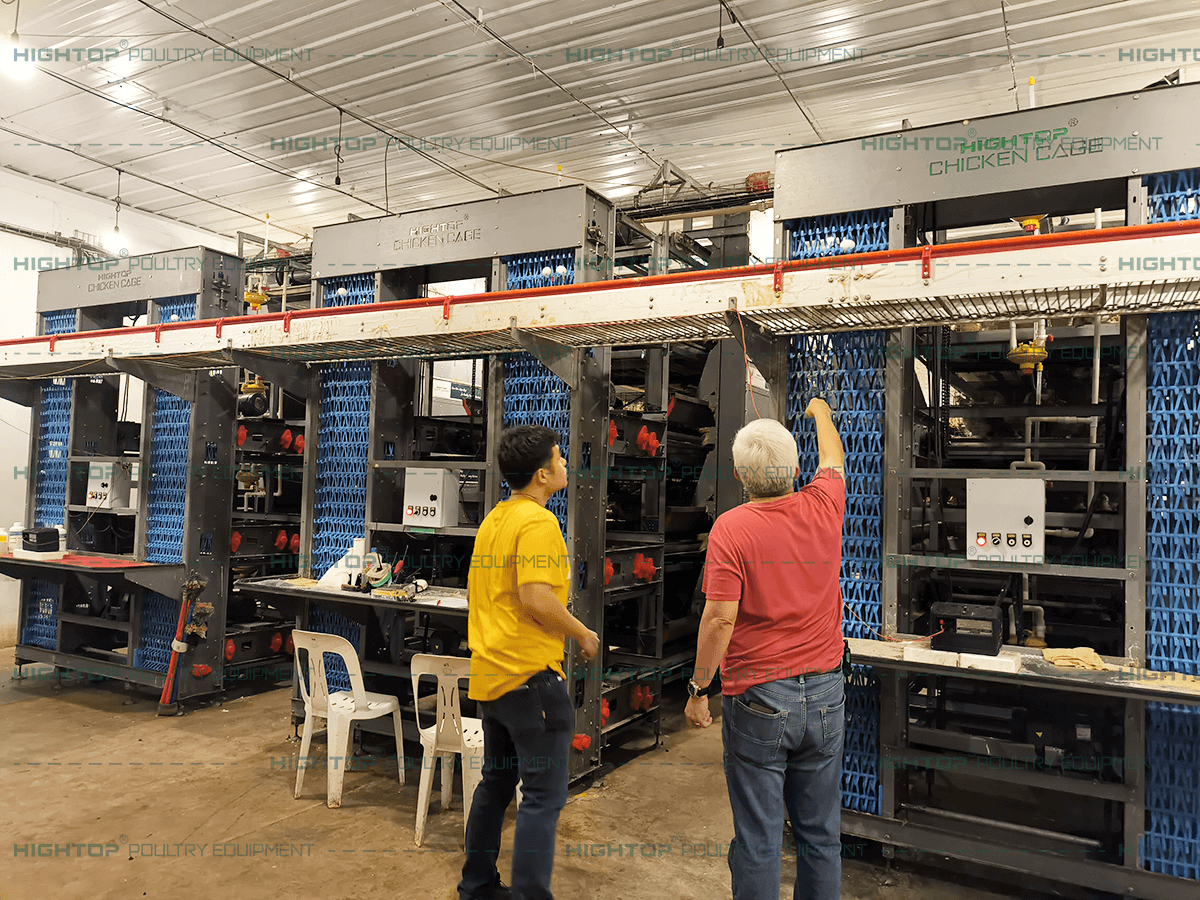

5. Installation, Commissioning, and Operational Support

During the installation phase, HIGHTOP Poultry Equipment coordinated closely with its cooperative installation team in the Philippines. Professional technicians provided guidance on cage assembly, alignment, and system integration, ensuring that the project progressed smoothly and according to schedule.

Once installation was completed, the system underwent comprehensive commissioning, including:

-

Testing of the automatic feeding and watering systems

-

Calibration of the central egg collection line

-

Trial operation of the egg grading machine

-

Overall system debugging to ensure stable performance

After the farm entered normal operation, HIGHTOP Poultry Equipment continued to provide after-sales support and technical follow-up. This proactive service approach helped the client quickly adapt to the automated systems and ensured long-term operational stability.

6. Why Choose HIGHTOP Poultry Equipment’s H-Type Automatic Layer Cages

Based on the successful implementation of this project, the client expressed strong recognition of the advantages offered by HIGHTOP Poultry Equipment’s H-type automatic layer cage system:

-

Strong and Stable H-Type Structure

The H-type frame provides excellent load-bearing capacity and long-term structural stability, making it ideal for multi-tier installations. -

High Automation Level

Integrated feeding, watering, and egg collection systems significantly reduce labor requirements and improve daily management efficiency. -

Efficient Egg Handling System

The central egg collection line combined with an egg grading machine minimizes egg loss, improves hygiene, and increases product value. -

Reliable Installation and After-Sales Service

Local installation support and ongoing technical follow-up reduce operational risks and ensure long-term system performance. -

Scalability for Future Expansion

The modular design allows the farm to expand production capacity in the future without major structural changes.

Conclusion

This project demonstrates that modern layer farming requires more than just equipment—it requires a reliable partner. By addressing the client’s previous pain points related to poor service and lack of support, HIGHTOP Poultry Equipment successfully delivered a complete, integrated solution that combines automation, efficiency, and long-term reliability.

With a modern steel structure chicken house, H-type automatic layer cages, a central egg collection line, and an egg grading machine, the farm is now well-positioned for stable production, improved egg quality, and sustainable growth.

For poultry producers seeking dependable automation and professional service, this case stands as a strong example of the value delivered by HIGHTOP Poultry Equipment.