Case Study: 40,448-Bird H-Type Automated Layer Farm Project in Ecuador

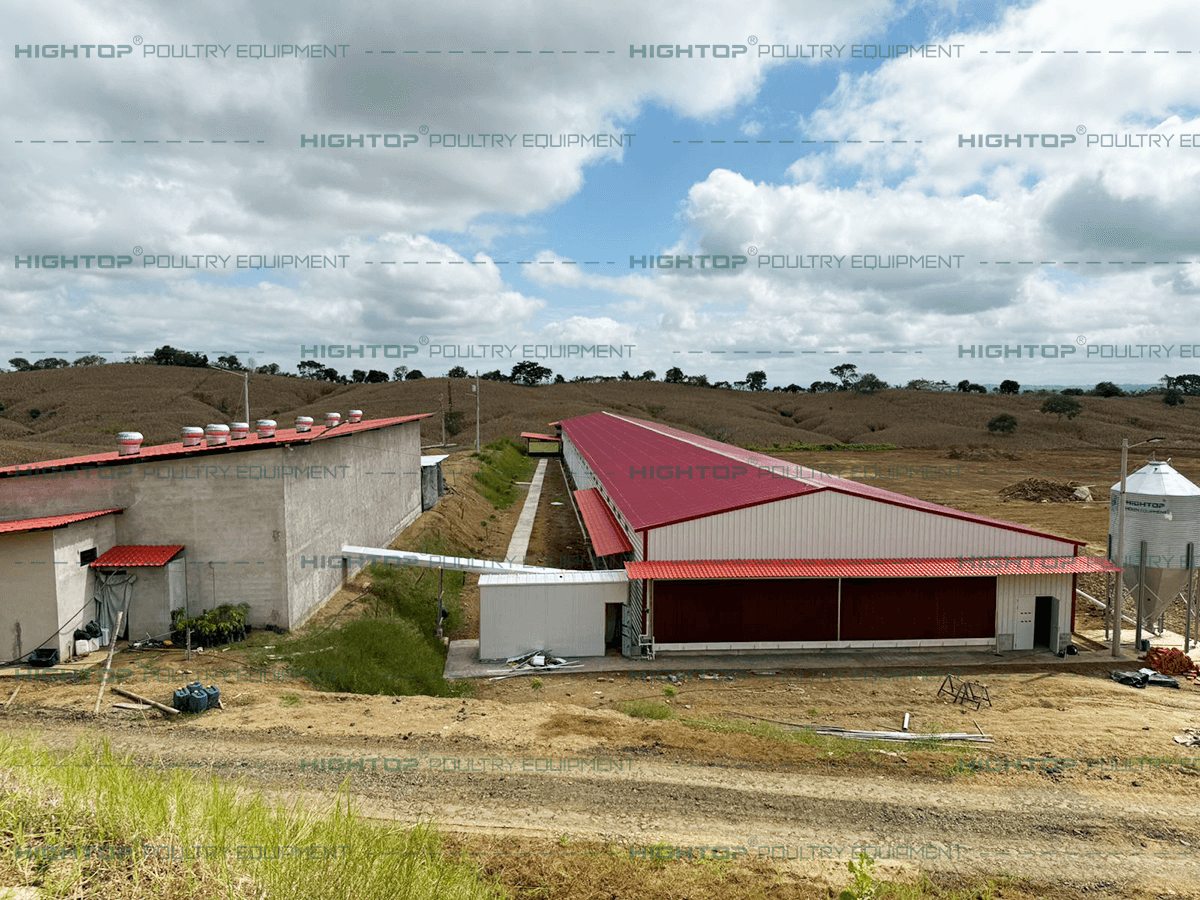

In 2025, HIGHTOP Poultry Equipment successfully completed a large-scale automated layer hen project in Ecuador. This project represents an important milestone for the modernization of poultry farming in South America, especially in regions transitioning from traditional open-house farming to advanced, automated production systems. With a capacity of 40,448 layers, the facility was designed to maximize productivity, reduce labor requirements, increase egg cleanliness, and improve the overall biological safety of the operation.

Project Overview

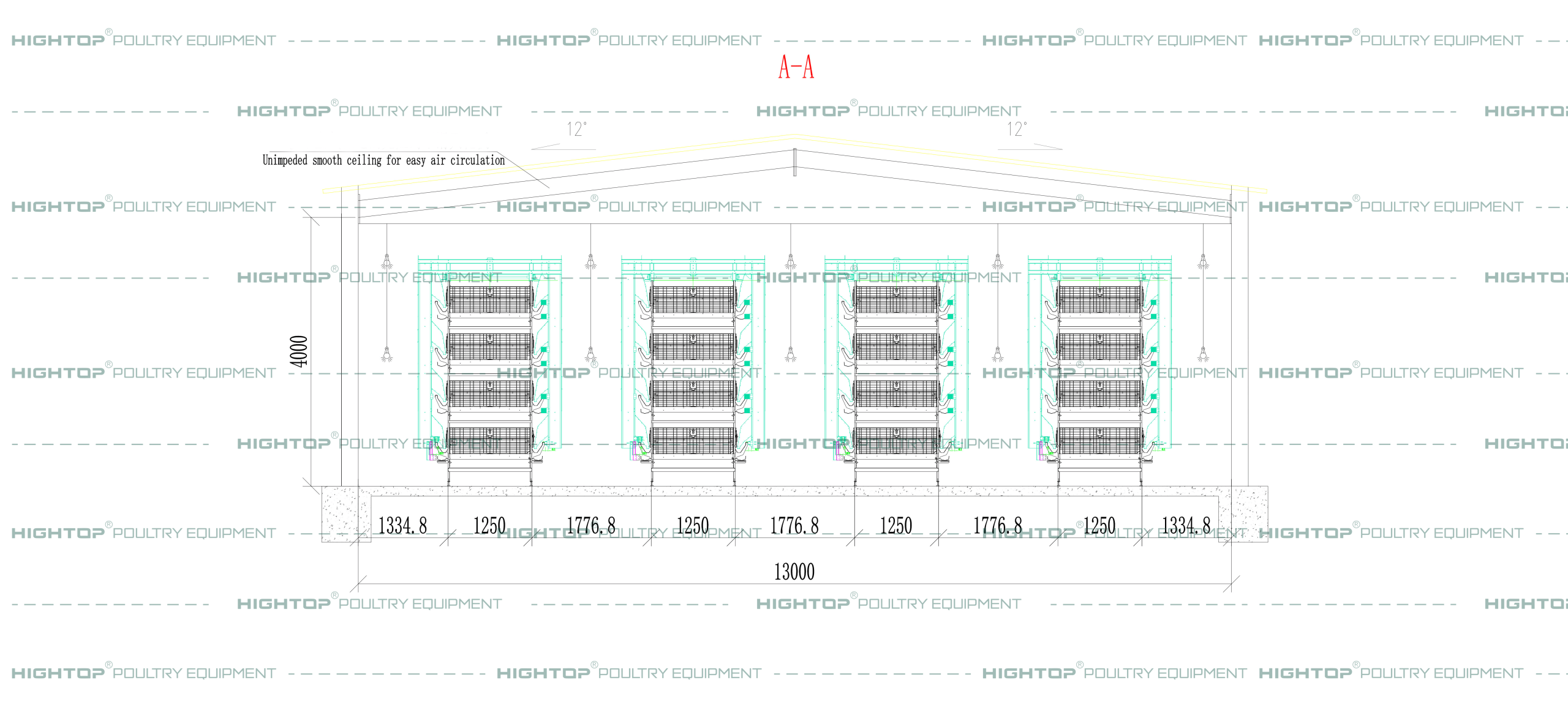

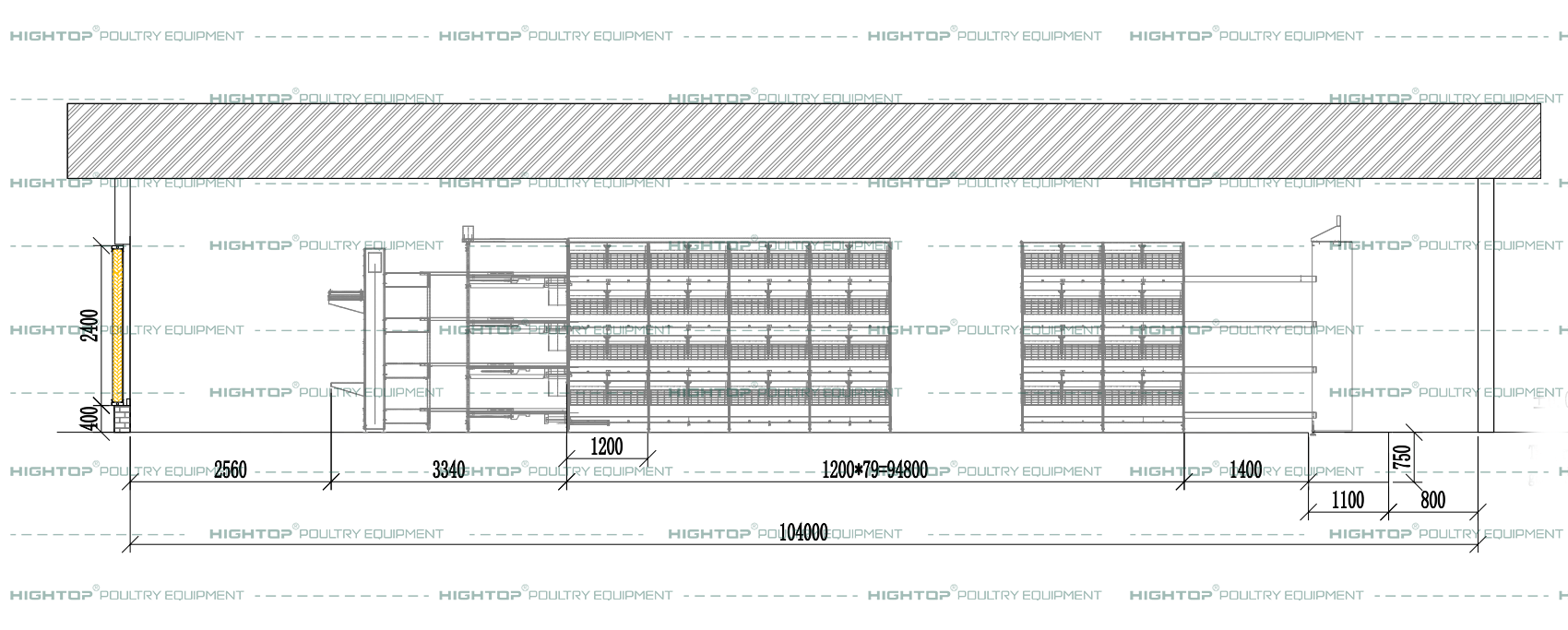

The farm is built with a full steel-structure house designed for durability, long-term stability, and compatibility with fully automated systems. The building specifications are as follows:

- Chicken House Dimensions:

104 m (length) × 13 m (width) × 4 m (height) - Cage Type:

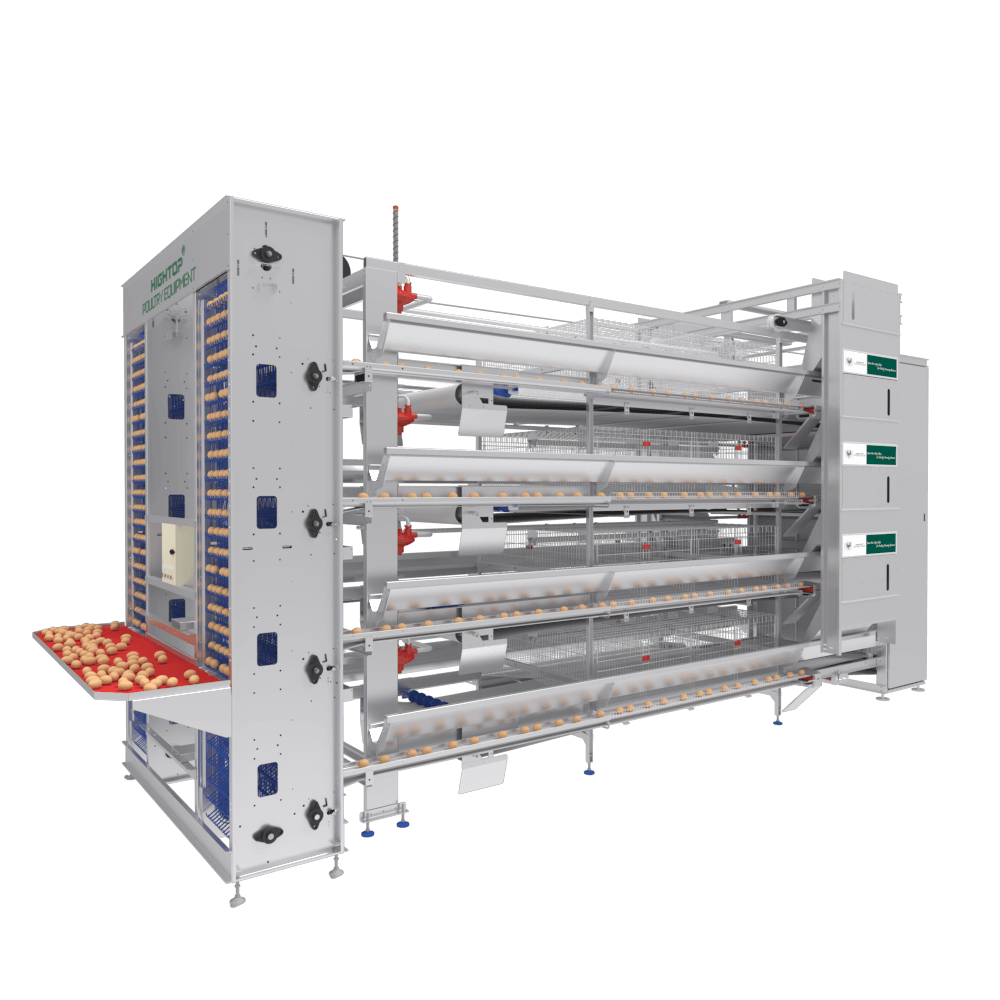

4 Tier H-type automated layer cage system - Cage Dimensions:

600 mm (length) × 625 mm (depth) × 490 mm (height) - Layout:

4 tiers × 4 rows, with 79 cage units per row - Bird Stocking Density:

8 chickens per cage, providing 468 cm² per bird - Total Farm Capacity:

40,448 laying hens

The project includes automation for feeding, drinking, egg collection, manure removal, and environmental control, ensuring a highly efficient and hygienic production system.

Installation Process

The installation was completed in several phases. HIGHTOP’s engineering team provided on-site support, remote technical assistance, and full project layout planning before equipment arrival. The installation process included:

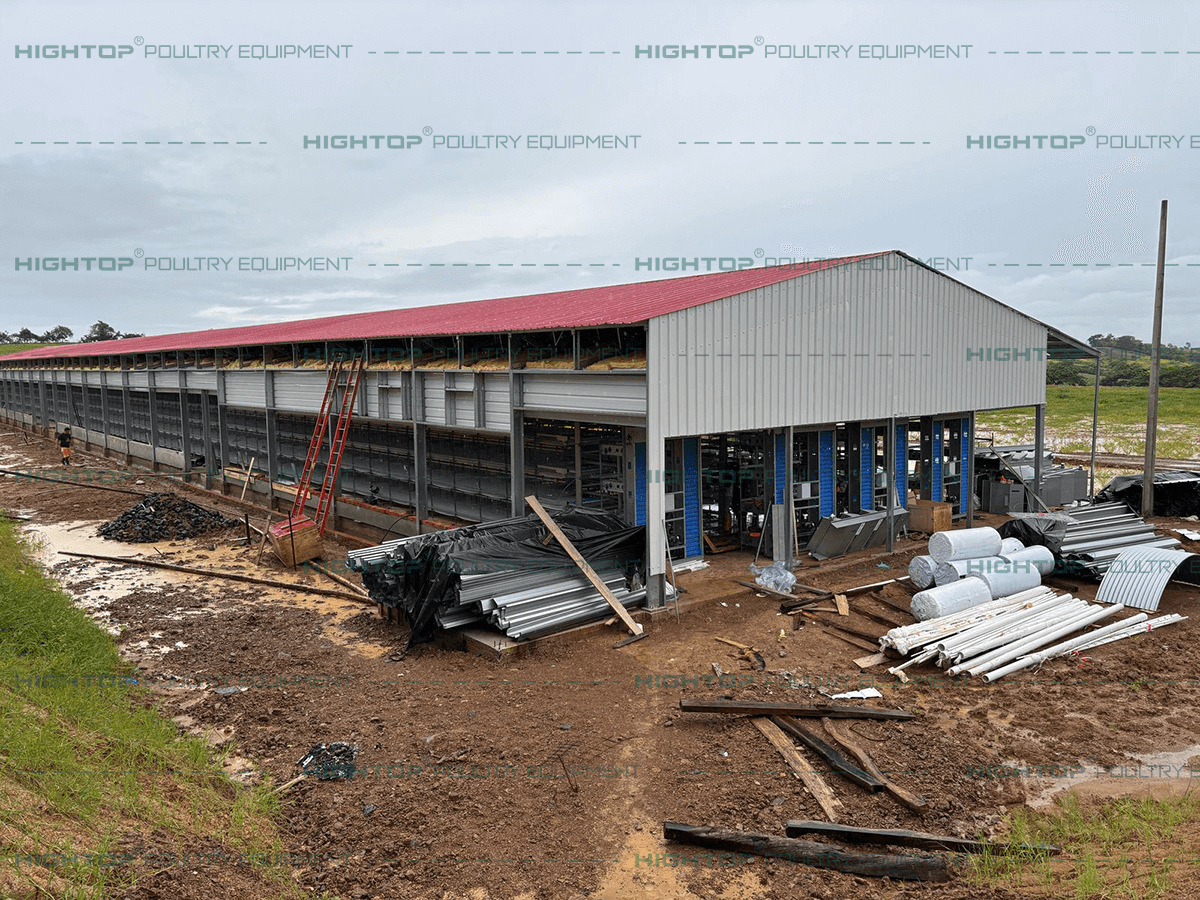

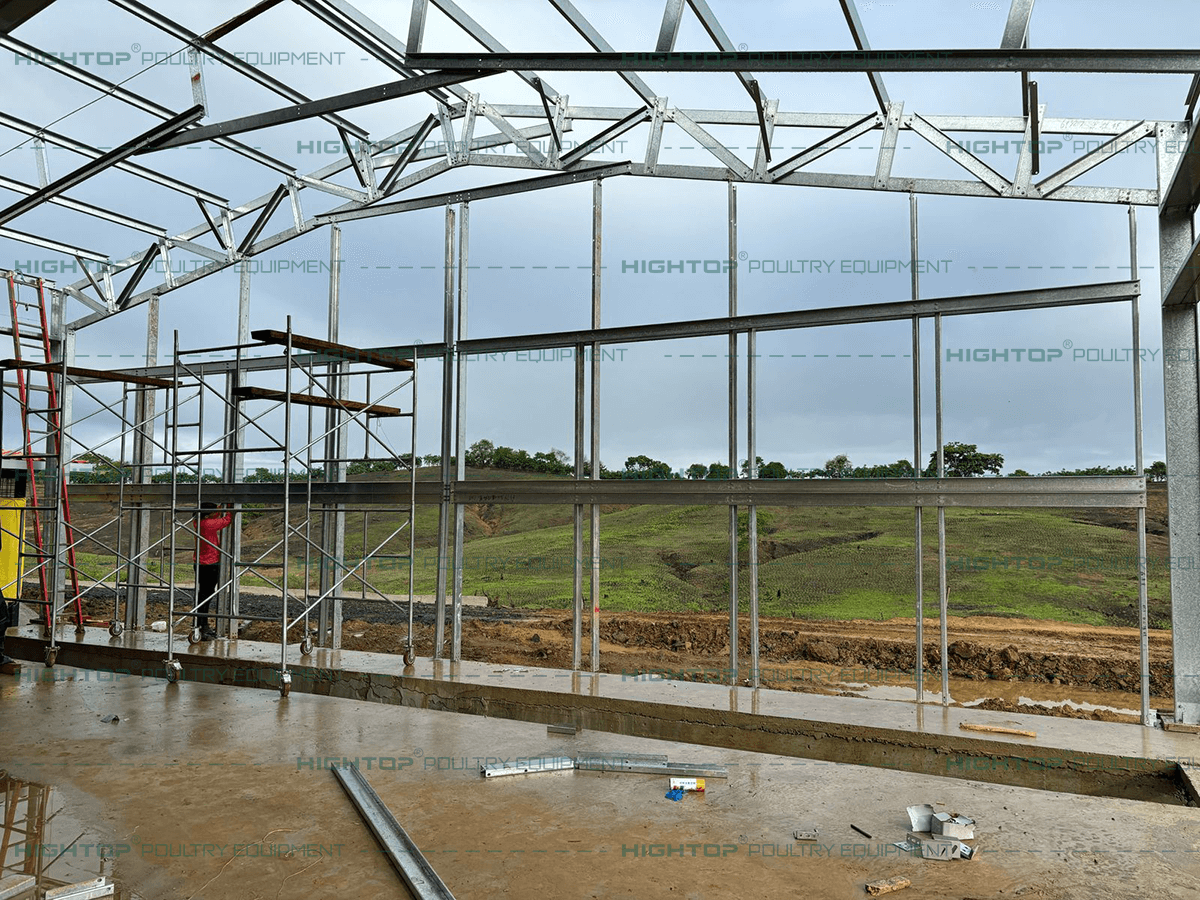

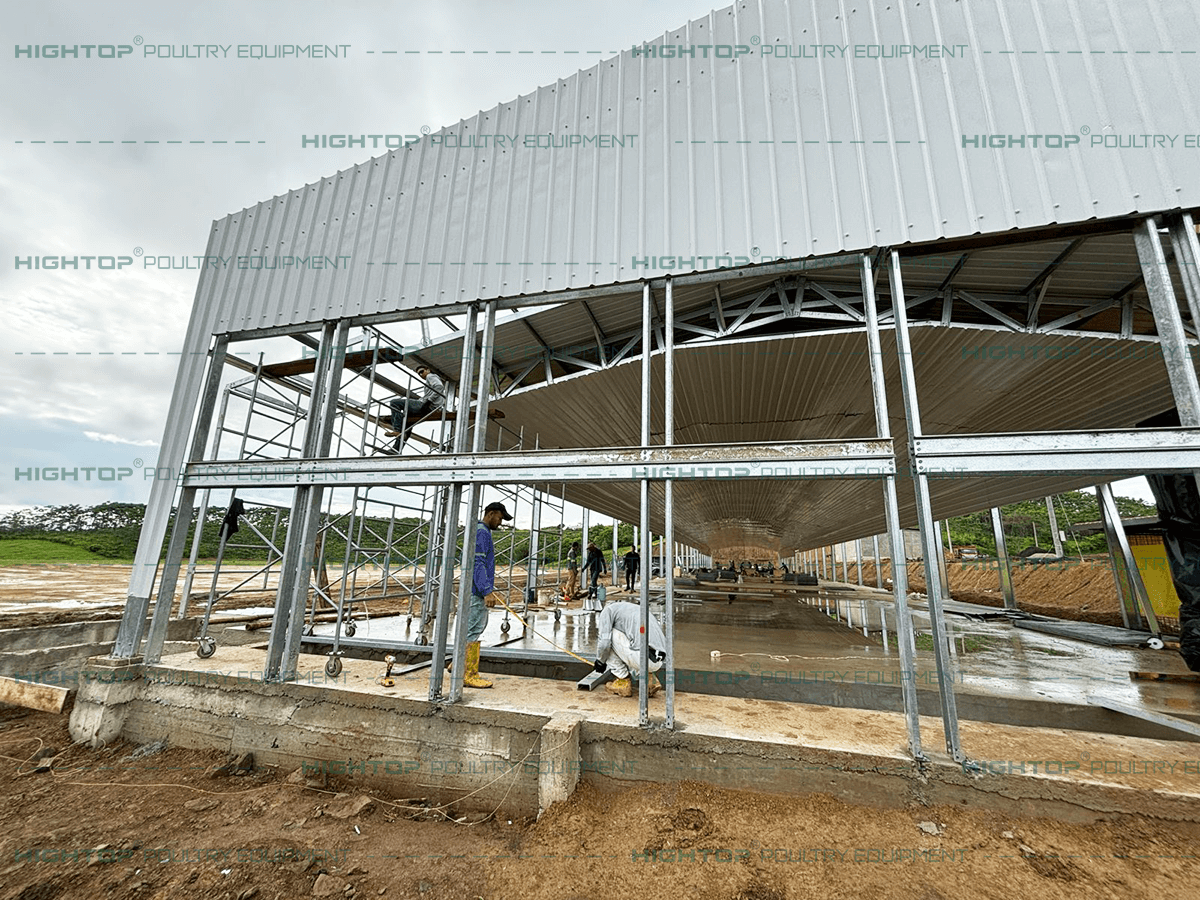

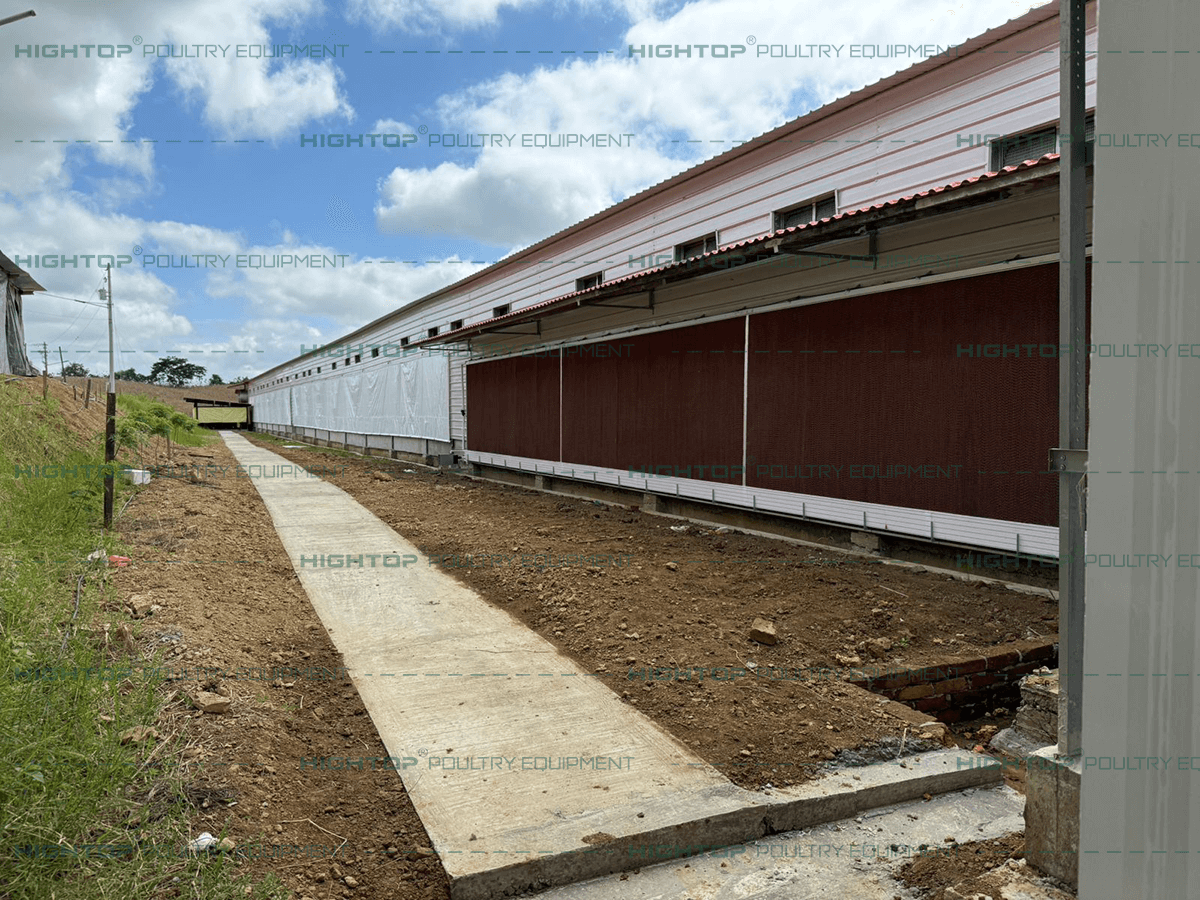

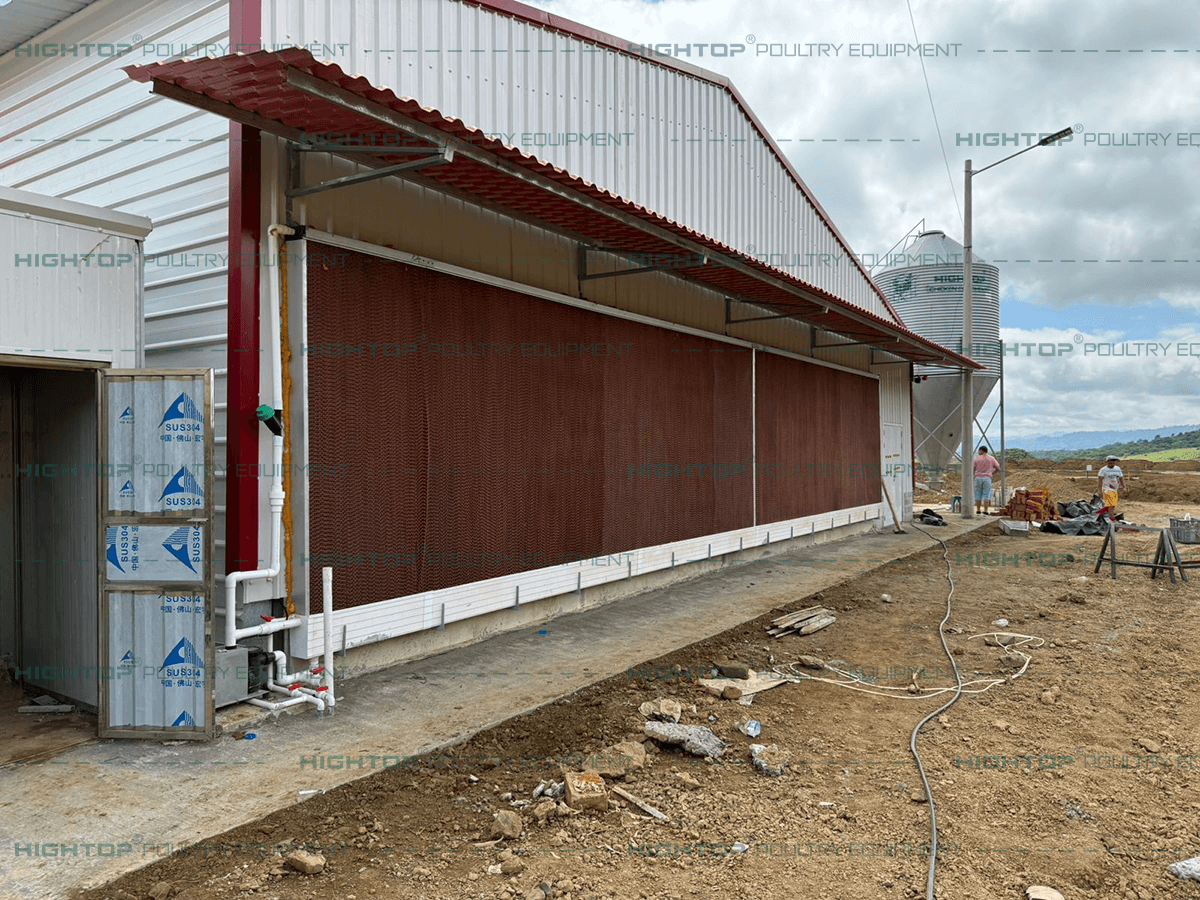

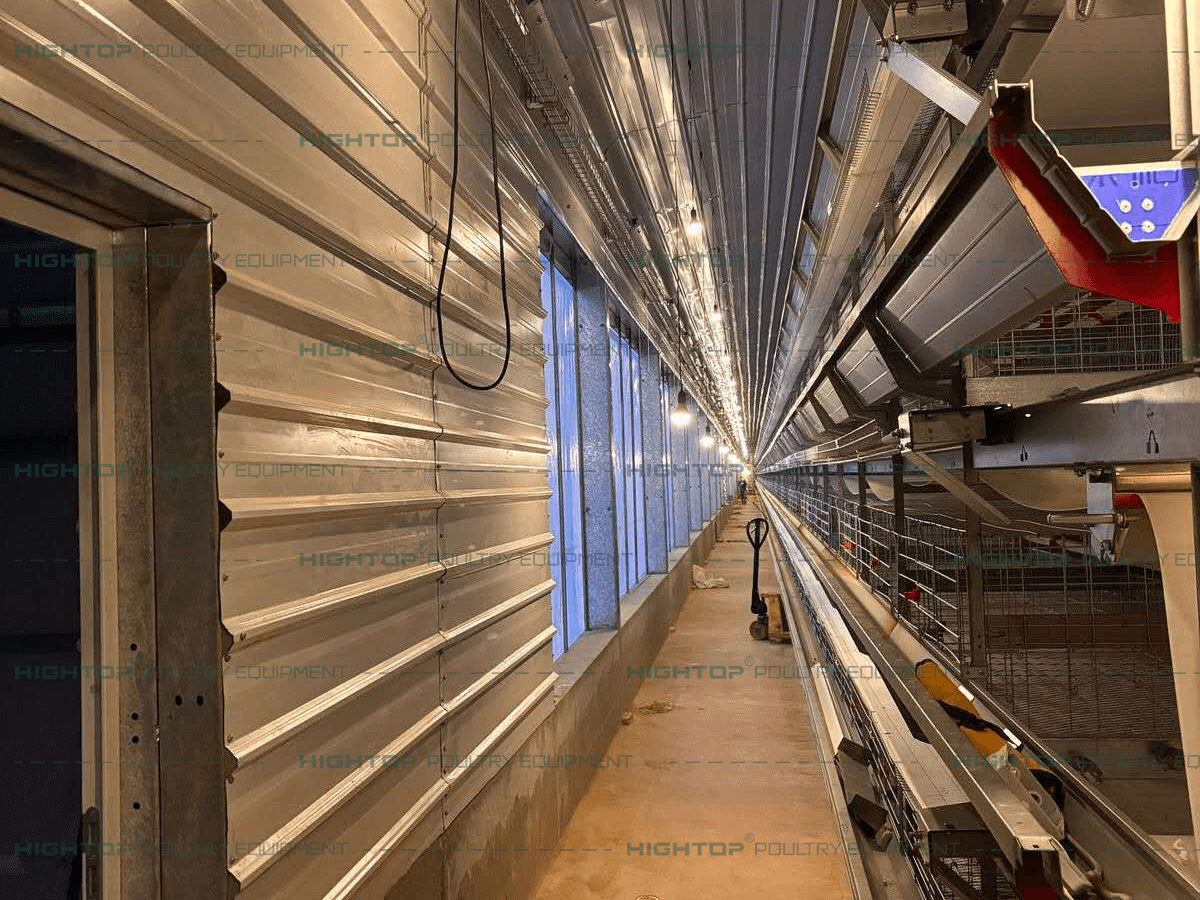

1. Steel Structure Construction

The first step involved constructing the steel-frame chicken house. The frame was specially treated with zinc and corrosion-resistant coatings suitable for Ecuador’s humid coastal environment. Ventilation openings, insulation, and control panel access points were pre-planned to support automated systems.

2. Equipment Installation

Once the steel structure was completed, installation of the automated H-type cage system began. This stage included:

-

Automated feeding lines

-

Water supply system with pressure regulators

-

Nipple drinkers with drip cups

-

Mechanical egg-collection belts

-

Manure removal conveyor belts

-

Environmental control system with fans and cooling pads

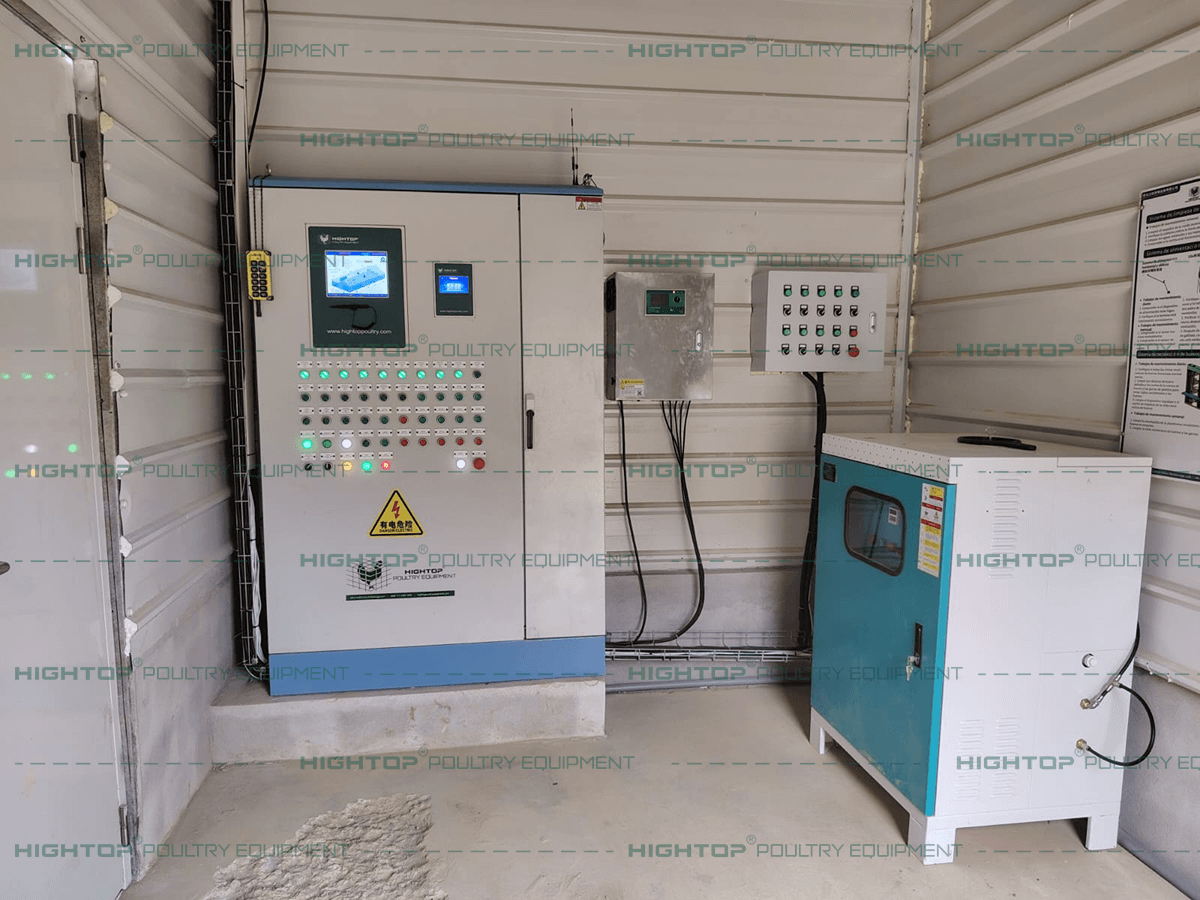

Electrical connections and panel calibration were conducted by HIGHTOP technicians to ensure seamless synchronization between mechanical and environmental systems.

3. Testing and Calibration

After assembly, the entire system underwent several rounds of testing:

-

Belt alignment and speed adjustments

-

Water line pressure testing

-

Egg collection and transfer flow testing

-

Ventilation and temperature mapping

-

Power safety and emergency shutdown testing

Only after all systems met operational standards was the farm prepared for live stocking.

Chicken Loading Phase

Once installation and system calibration were completed, the farm proceeded with chicken loading. The hens were introduced into the cages according to the planned stocking density of 8 birds per unit.

During this phase, several key advantages of the H-type automated cage design became evident:

-

The wide doors and optimized cage structure allowed fast and stress-reduced placement of pullets.

-

Automatic drinkers ensured immediate access to clean water.

-

Feed trough design allowed uniform feed access, improving early adaptation.

-

Environmental control systems maintained optimal temperature and humidity, reducing stocking stress.

Within the first two weeks, the birds adapted smoothly to their new environment, demonstrating good activity levels, uniform feed intake, and stable behavior.

Advantages of HIGHTOP’s H-Type Automated Layer Cage System

The farm owner selected HIGHTOP equipment to increase efficiency, improve hygiene standards, and reduce reliance on manual labor. Several notable benefits include:

1. Space-Saving and High Density Production

The vertical multi-tier cage structure allows the farm to house over 40,000 birds in a footprint that would traditionally only support a fraction of that capacity. This greatly improves land-use efficiency and capital return.

2. Fully Automated Operation

This system integrates automation for critical production processes:

| Function | Automation Benefit |

|---|---|

| Feeding | Even feed distribution saves time and reduces waste |

| Drinking | Constant access to clean water protects flock health |

| Manure removal | Daily removal prevents ammonia buildup and reduces disease spread |

| Egg collection | Eggs remain clean and undamaged, increasing sale value |

| Climate control | Ensures ideal temperature, humidity, and airflow |

Through automation, labor intensity is reduced by 70–85%, significantly lowering operating costs.

3. Improved Bird Health and Biosecurity

Automatic waste removal and controlled ventilation greatly reduce disease pressure by:

-

Minimizing ammonia accumulation

-

Lowering parasite and pathogen growth

-

Keeping hens separated from manure contact

This results in lower mortality rates and improved egg production performance.

4. Strong and Durable Construction

All cages are manufactured from Q235 high-strength steel with either hot-dip galvanizing or aluminum-zinc coating. These treatments provide:

-

Corrosion resistance

-

Extended lifespan of 15–20 years

-

Reduced maintenance

This durability makes the system ideal for humid, coastal, or ammonia-rich environments.

5. Higher Egg Cleanliness and Productivity

The mechanical belt egg-collection system gently transports eggs from the cages to the storage area, minimizing breakage. Clean eggs require no hand-cleaning, improving final grading quality and sales price.

Customer Feedback

Following installation and flock introduction, the customer reported strong early performance indicators. Key results included:

-

Smooth start-up phase with birds adapting quickly to automated feeding and water systems.

-

Reduced labor requirements—only 2–3 workers are needed for daily farm management.

-

Cleaner environment with significantly reduced odors due to daily manure removal.

-

Higher egg consistency and improved shell cleanliness compared to previous semi-manual systems.

The farm owner highlighted three major advantages:

“The system is very efficient and easy to operate.”

“Labor costs dropped significantly after automation.”

“We are extremely satisfied with the egg cleanliness and production stability.”

The customer also praised HIGHTOP for timely communication, onsite support, and reliable after-sales guidance.

Summarize

This project demonstrates the effectiveness of transitioning from traditional poultry farming to fully automated systems. With advanced H-type layer cages, automation technology, and durable construction, the Ecuador farm achieved:

-

Higher productivity

-

Better bird welfare

-

Reduced labor costs

-

Improved biosecurity

-

Faster operational efficiency

-

Stronger profitability

HIGHTOP Poultry Equipment remains committed to supporting farms worldwide with modern, cost-effective, and innovative poultry systems designed to improve long-term farming success.