Ecuador Case Study: A-Type Automatic Brooding Cage System with Prefabricated Steel Structure Chicken House

Project Overview

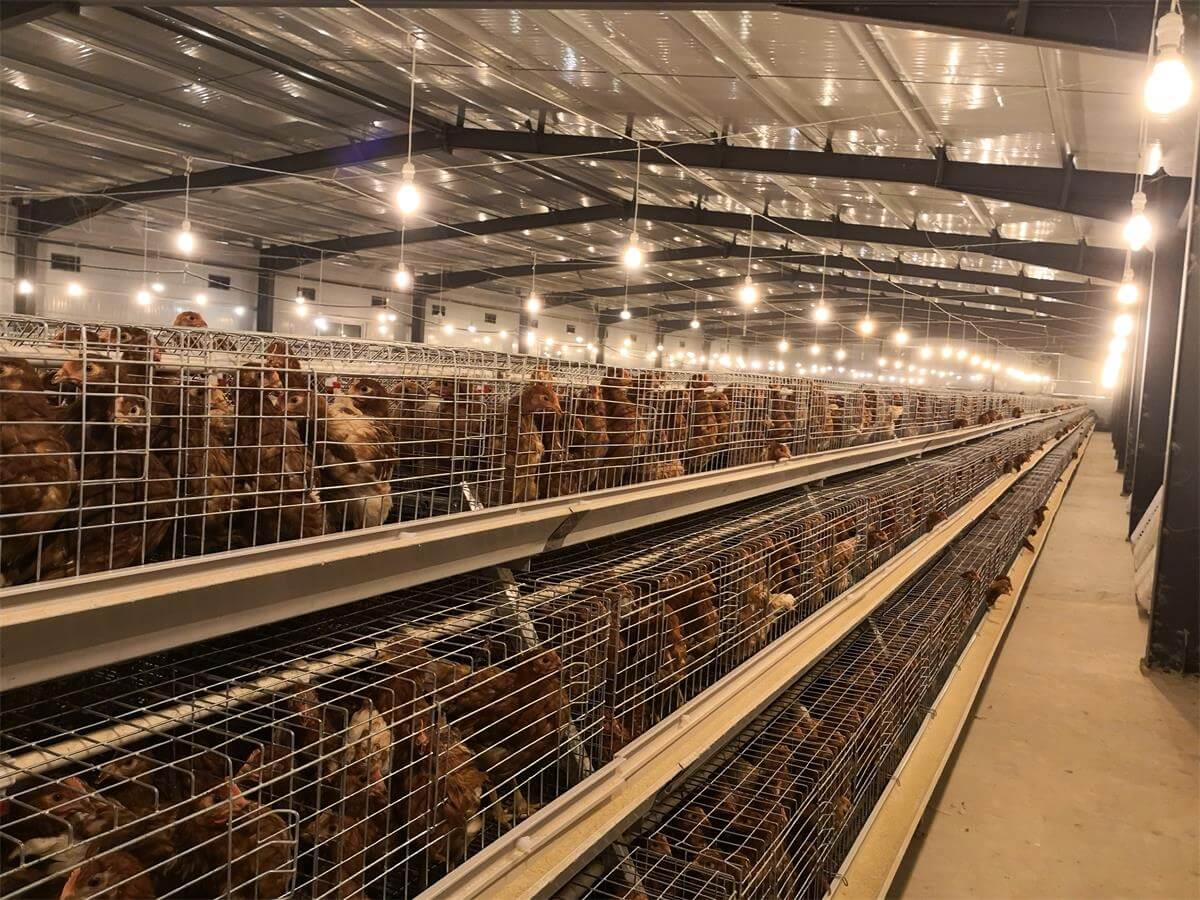

As the global poultry industry continues to move toward higher efficiency, better biosecurity, and lower labor dependency, more poultry farms are transitioning from traditional floor rearing systems to automated cage-based brooding solutions. This case study presents a complete A-Type Automatic Chick Brooding Cage project implemented by HIGHTOP Poultry Equipment in Ecuador, combining intensive cage rearing with a prefabricated steel structure chicken house.

The project focuses on pullet rearing from day-old chicks to 16 weeks of age, laying a solid foundation for future egg production. Through optimized cage design, full automation, and a well-engineered steel structure poultry house, this farm successfully increased stocking density, improved flock uniformity, reduced mortality, and achieved long-term operational stability.

Project Background and Objectives

The customer’s primary goals were:

-

Increasing the number of chicks raised without increasing the land area used

-

Improve biosecurity and reduce disease risks during the brooding and growing stages

-

Reduce labor input through automation

-

Ensure chicks grow uniformly and develop healthily

-

Build a durable poultry house with a long service life

After technical evaluation and capacity planning, HIGHTOP proposed an A Type Automatic Brooding Cage System integrated with a prefabricated steel structure chicken house, tailored to local electrical standards and farm conditions

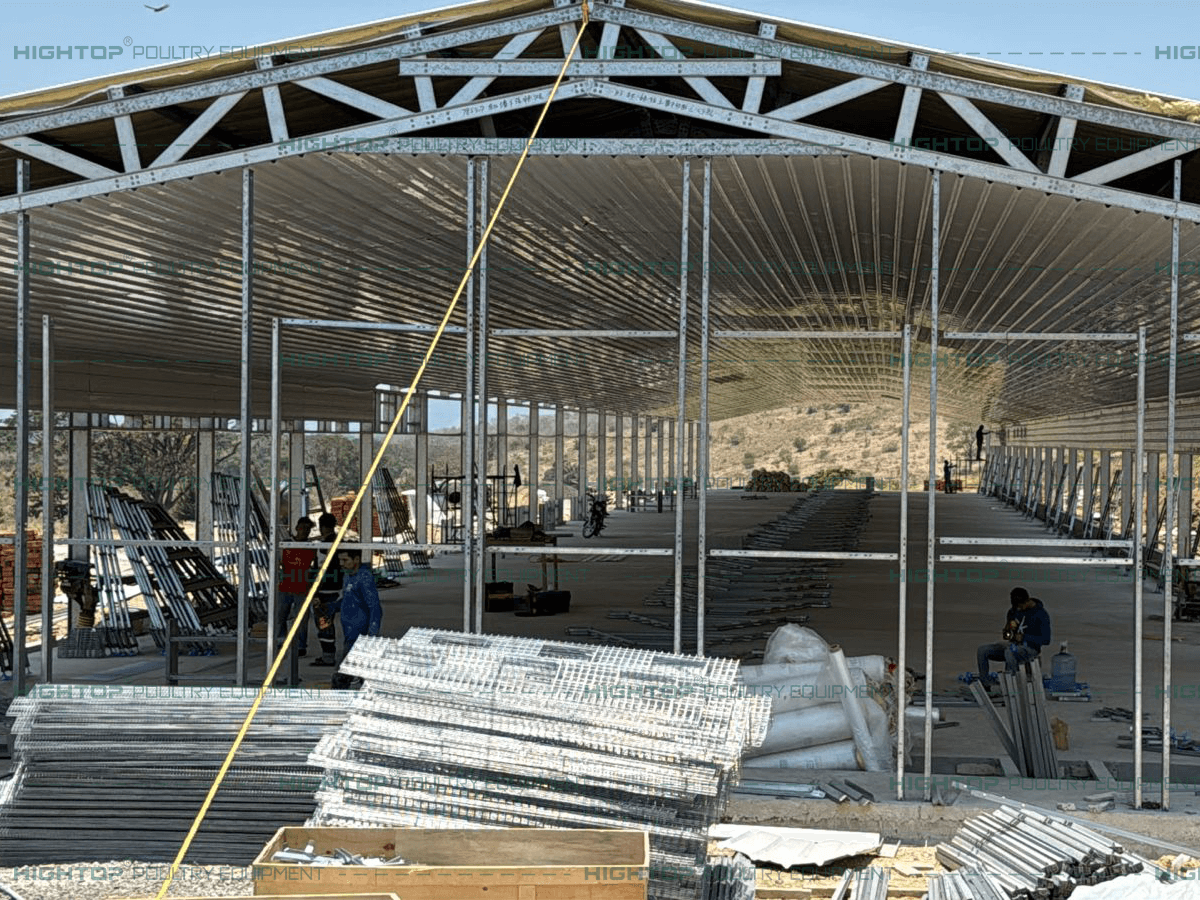

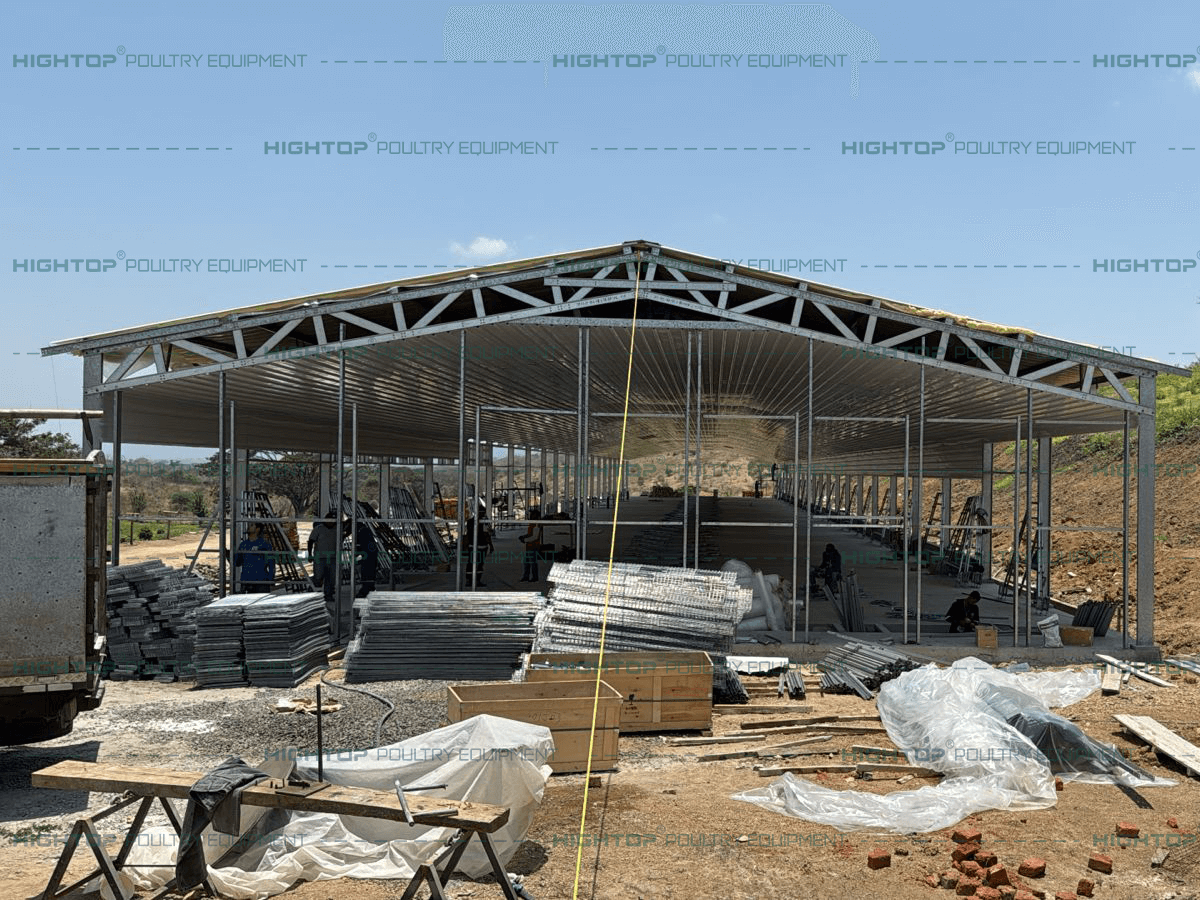

Prefabricated Steel Structure Chicken House

1. Building Dimensions:

- Length: 102 m

- Width: 15 m

- Height: 3.5 m

2. Structure Type:

- Prefabricated steel structure

- Bolted installation

- High wind resistance and structural stability

3. Electrical Standard:

- 380V / 60Hz

- Three-phase electricity

The steel structure chicken house was designed to accommodate the A-Type brooding cage system while ensuring smooth airflow, easy maintenance, and long-term durability.

Technical Configuration of the Project

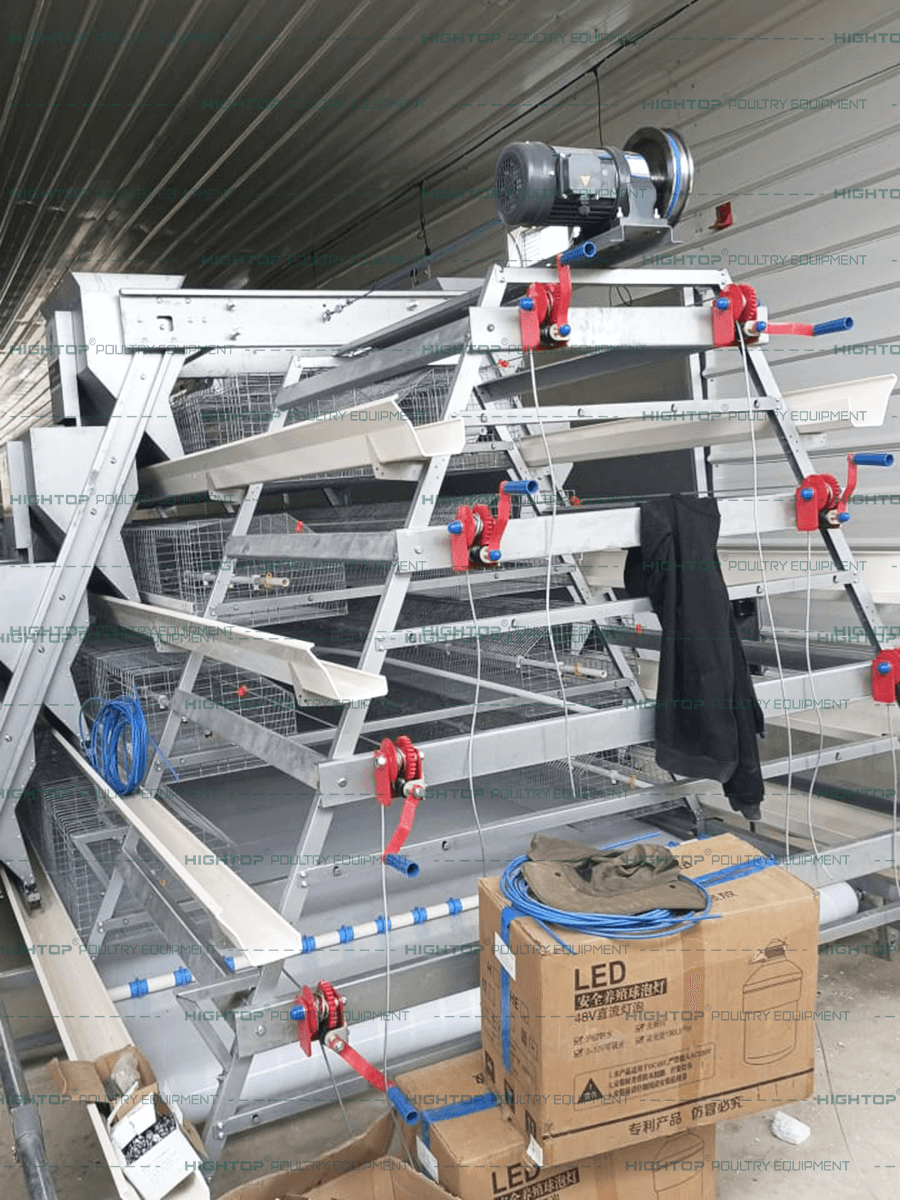

A-Type Automatic Brooding Cage System

Cage Type: A-Type Automatic Brooding Cage

Layout:

- 4 rows

- 4 tiers

- 47 sets per row

Total Cage Sets: 47 × 4 = 188 sets

Total Chick Capacity: 40,608 pullets

Cage Mesh Specifications:

- 1950 × 350 × 500 mm

- 3 nests per cage

Materials:

- Hot-dip galvanized steel

- High corrosion resistance

Designed service life: 15–20 years

Why Choose an A-Type Automatic Brooding Cage System?

Compared with traditional flat rearing systems, the A-Type brooder cage offers multiple technical and economic advantages.

Advantage 1: At Least 50% Higher Stocking Density

One of the most significant benefits of using an A-Type brooding cage system is space efficiency.

By utilizing vertical space through multi-tier cage design, the farm increased the number of pullets raised per unit area by at least 50% compared to floor rearing. This allowed the customer to maximize production capacity without expanding the poultry house footprint.

This advantage is especially critical for farms facing land constraints or aiming to reduce construction investment.

Advantage 2: Complete Separation of Pullets and Manure

In this system, pullets are fully separated from manure:

-

Manure drops directly to the ground beneath the cages

-

No direct contact between birds and feces

-

Significantly reduced dust levels inside the chicken house

This design greatly lowers the risk of:

-

Fecal contamination

-

Bacterial and parasitic infections

-

Respiratory diseases caused by dust and ammonia

As a result, the farm achieved a lower mortality rate and healthier flock development during the critical brooding phase.

Advantage 3: Improved Feed Efficiency and Uniform Growth

The A-Type brooding cage system minimizes unnecessary movement of pullets:

-

Birds do not waste energy walking or scratching

-

More energy is converted into growth

Additionally:

-

Each cage provides sufficient feeding and drinking positions

-

Feed distribution is uniform across all tiers

-

Water supply is stable and hygienic

This results in:

-

Better body weight uniformity

-

Reduced feed wastage

-

Lower feed cost per bird

Uniform pullets are essential for stable performance in the subsequent laying stage.

Advantage 4: Easier Observation and Management

The cage system allows farmers to:

-

Clearly observe bird behavior

-

Identify clustering or stress early

-

Detect weak or slow-growing chicks quickly

Early intervention significantly improves survival rates and reduces long-term losses.

At the same time, the system eliminates the need for litter materials, which are typically required in flat rearing systems and represent a recurring operational cost.

Advantage 5: Full Automation Reduces Labor Costs

This project achieved a high level of automation:

-

Automatic feeding

-

Automatic drinking

-

Automatic manure cleaning

-

Automated lighting schedules

-

Centralized environmental control

Thanks to automation:

-

Daily labor requirements were greatly reduced

-

Human error in feeding and management was minimized

-

Operational efficiency was significantly improved

This makes the system suitable for farms seeking scalable and standardized pullet production.

Advantage 6: Durable Materials and Long Service Life

All cage components are manufactured using hot-dip galvanized steel, providing:

-

Excellent corrosion resistance

-

High structural strength

-

Long-term reliability in humid poultry environments

With proper maintenance, the system offers a 15–20 year service life, ensuring a strong return on investment.

Advantage 7: Ideal for Enclosed Chicken Houses

The A-Type automatic brooding cage system performs best in enclosed or semi-enclosed chicken houses equipped with:

-

Automatic ventilation

-

Temperature control

-

Environmental monitoring

In this Ecuador project, the prefabricated steel structure chicken house ensured:

-

Stable internal climate

-

Efficient airflow distribution

-

Comfortable brooding conditions

These factors are essential for chick survival and healthy development.

Results and Performance Summary

After implementation, the farm achieved:

-

Increased pullet capacity without land expansion

-

Improved survival rate during brooding

-

The weight of 16-week-old chickens is closer to the average weight.

-

Reduced labor and operating costs

-

Stable and controllable brooding environment

The project fully met the customer’s production and management goals.

Why Choose HIGHTOP A-Type Automatic Brooding Cage Systems?

HIGHTOP provides complete pullet rearing solutions, including:

-

Equipment design and customization

-

Cage manufacturing

-

Prefabricated steel structure chicken houses

-

Automation system integration

-

Technical guidance and after-sales support

Each project is engineered based on:

-

Chicken quantity

-

Growth stage requirements

-

Farm layout

-

Local electrical and environmental conditions

Conclusion

This Ecuador project demonstrates how an A-Type Automatic Brooding Cage System, combined with a prefabricated steel structure chicken house, can dramatically improve pullet rearing efficiency, biosecurity, and economic performance.

For poultry farms aiming to modernize their brooding operations, reduce labor dependency, and build a sustainable foundation for future egg production, the A-Type automatic brooding cage system from HIGHTOP Poultry Equipment represents a reliable and cost-effective solution.