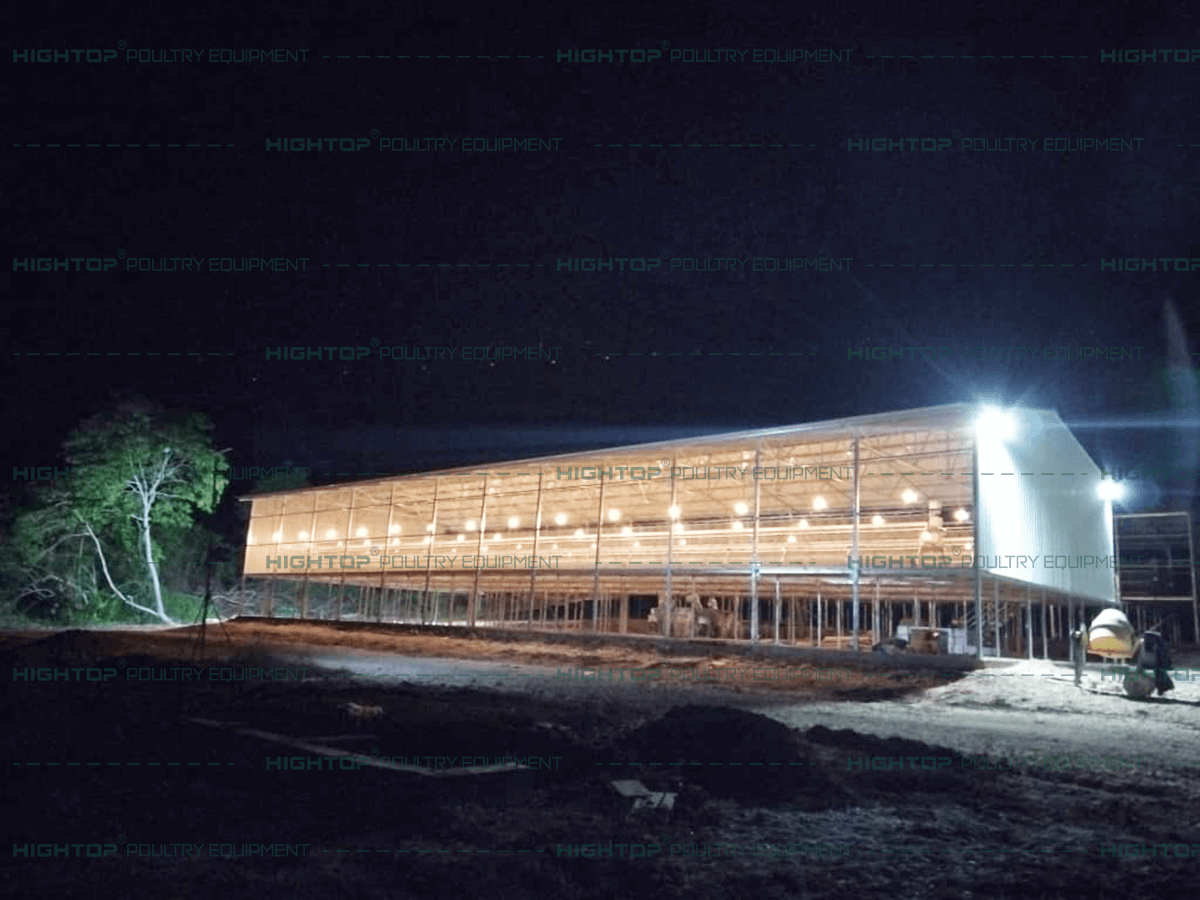

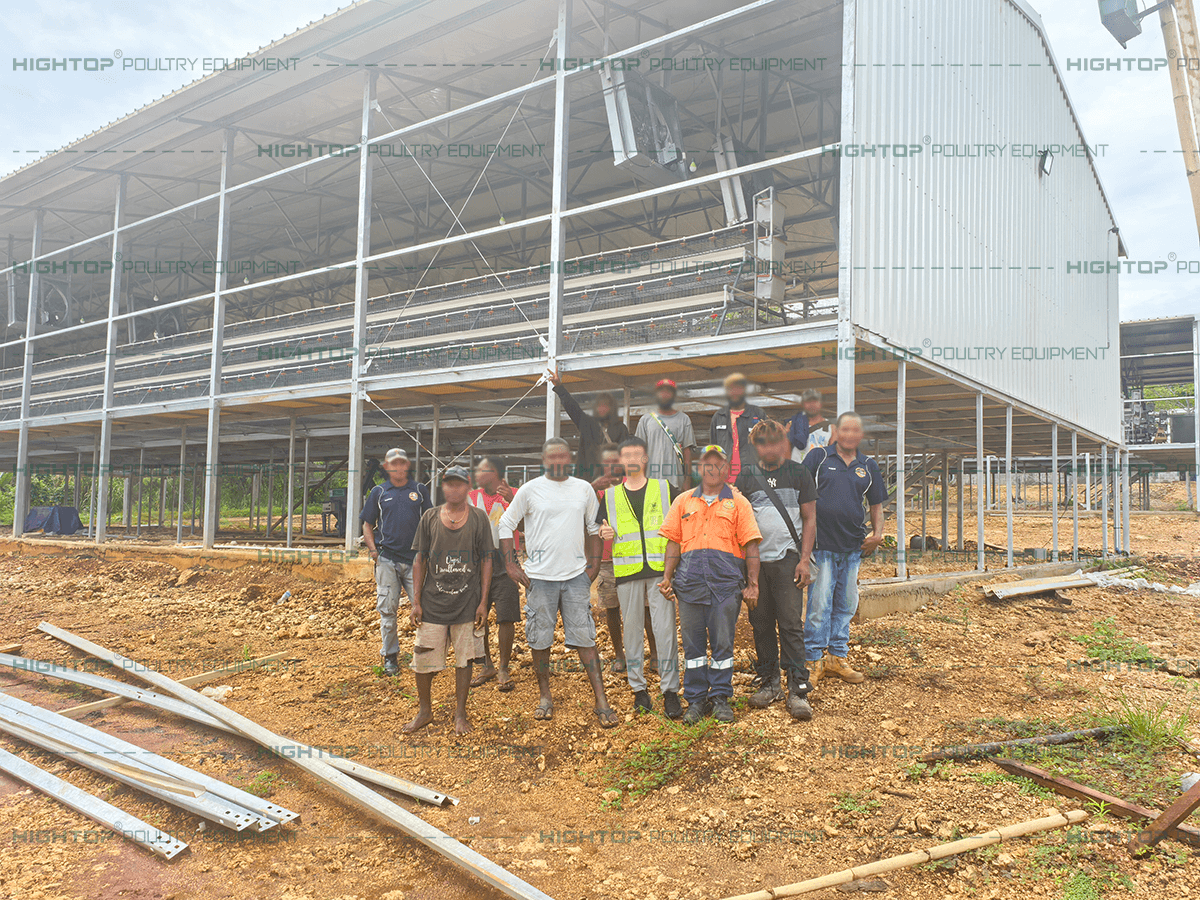

Case Study: Egg Laying Hen Farming Project in Papua New Guinea Using Conventional Chicken Cages

1. Project Background and Client Objectives

This project is located in Papua New Guinea, a developing poultry market where egg consumption is steadily increasing, while farm investment budgets remain limited. The local climate is tropical, with high humidity and temperatures, which requires practical poultry house design and reliable equipment.

The client is a small-to-medium poultry farmer seeking to establish a commercial layer farm with controlled investment and stable production. Instead of adopting a fully automated cage system, the client chose a cost-effective solution based on ordinary layer cages combined with a semi-automatic feeding cart.

The main objectives of the project were:

- To build a commercial layer farm with low initial investment

- To achieve stable egg production using simple and reliable equipment

- To improve feeding efficiency while avoiding high automation costs

- To maintain flexibility for future expansion

After technical evaluation and project planning, the farm adopted a standard 3-tier layer cage system with semi-automatic feeding equipment, forming a practical production model suitable for emerging poultry markets.

2. Project Overview and Technical Parameters

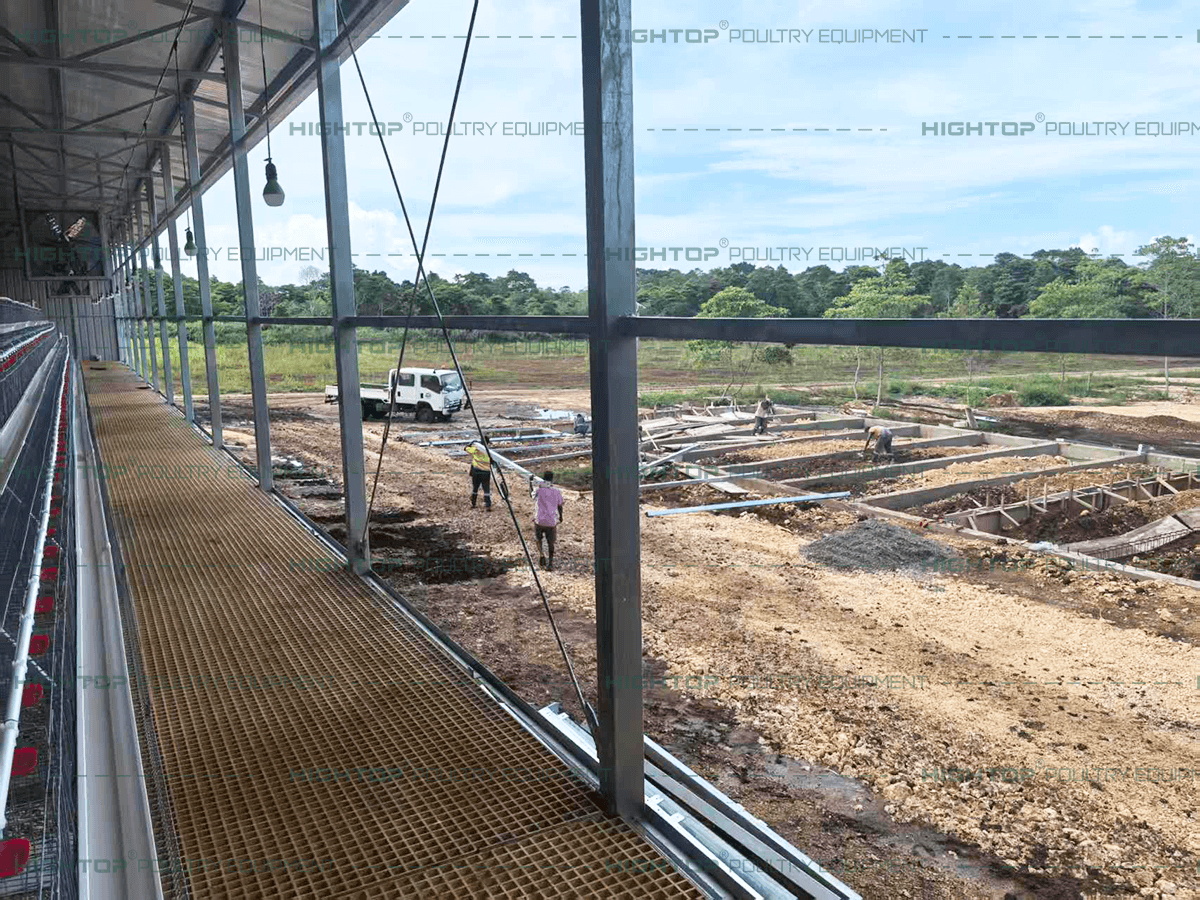

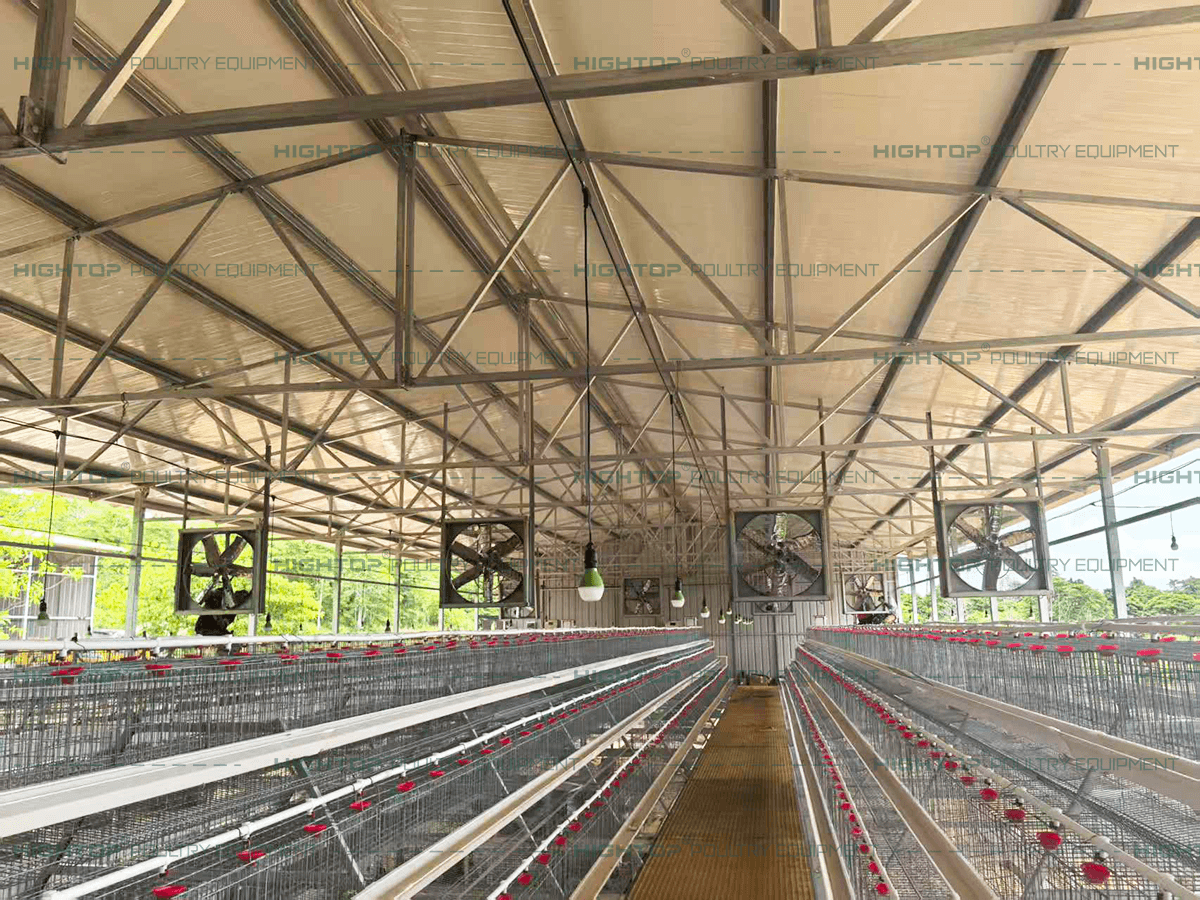

2.1 Chicken House Configuration

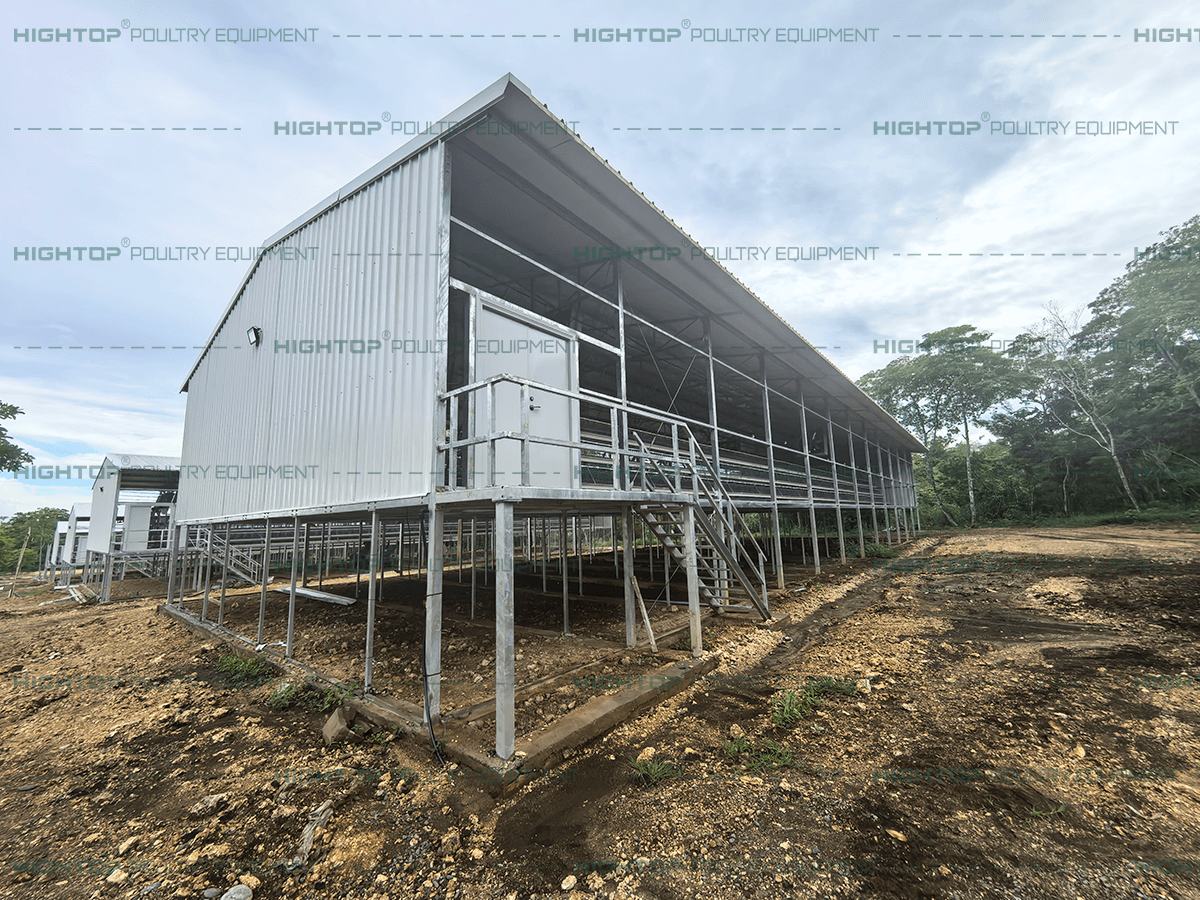

The farm consists of six identical layer houses designed with a simple steel structure and rational layout.

- Chicken house size (each): 36 m × 12 m × 3.3 m

- Number of houses: 6

- Total farm capacity: 25,920 layer hens

Each house was designed to maximize space utilization while maintaining adequate ventilation and management convenience.

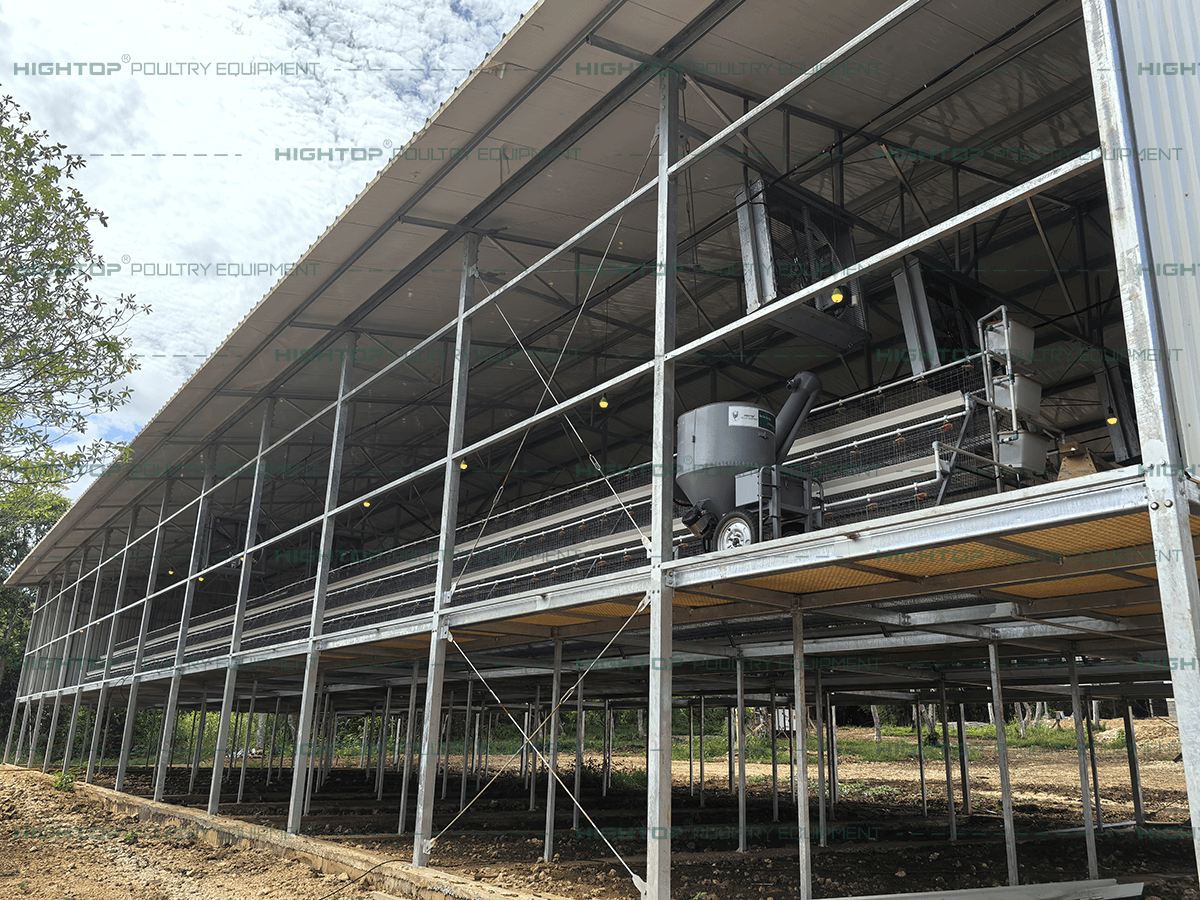

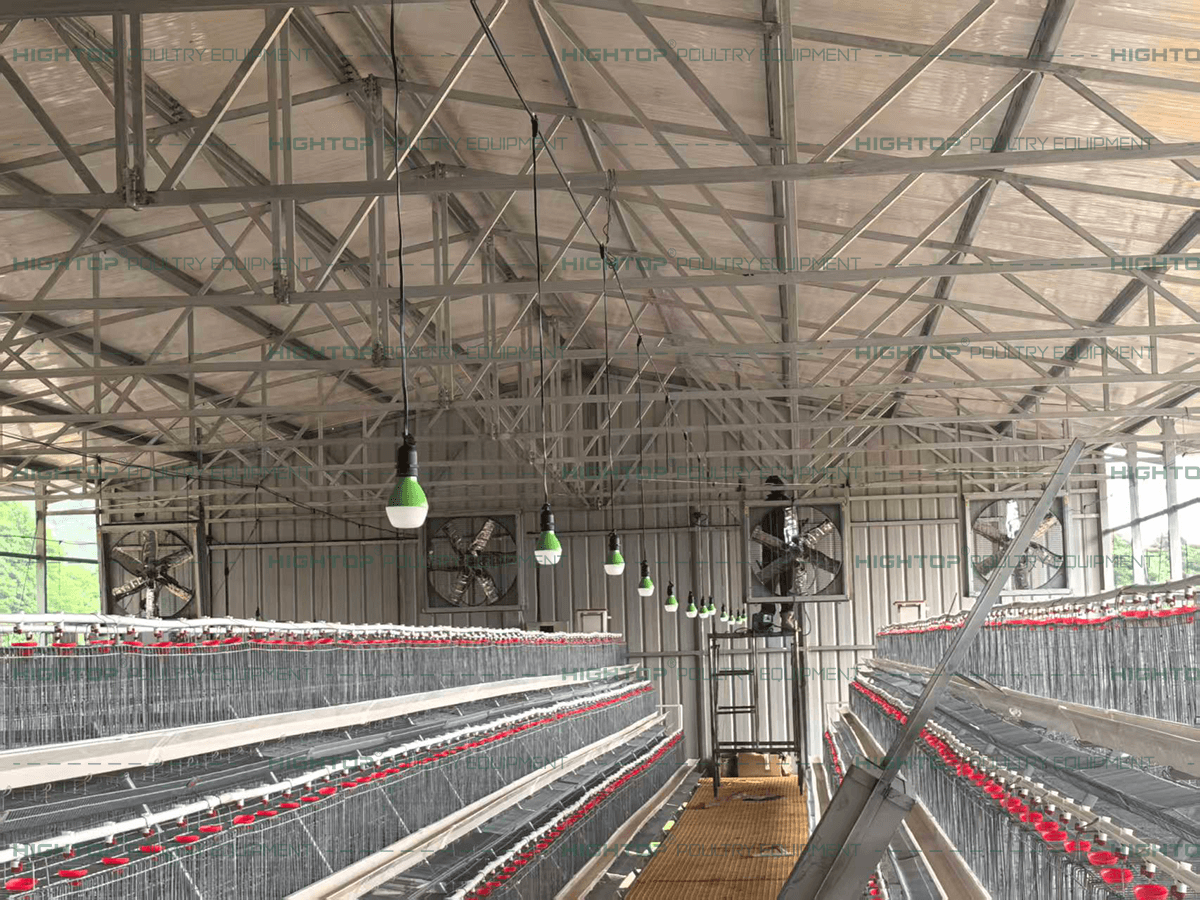

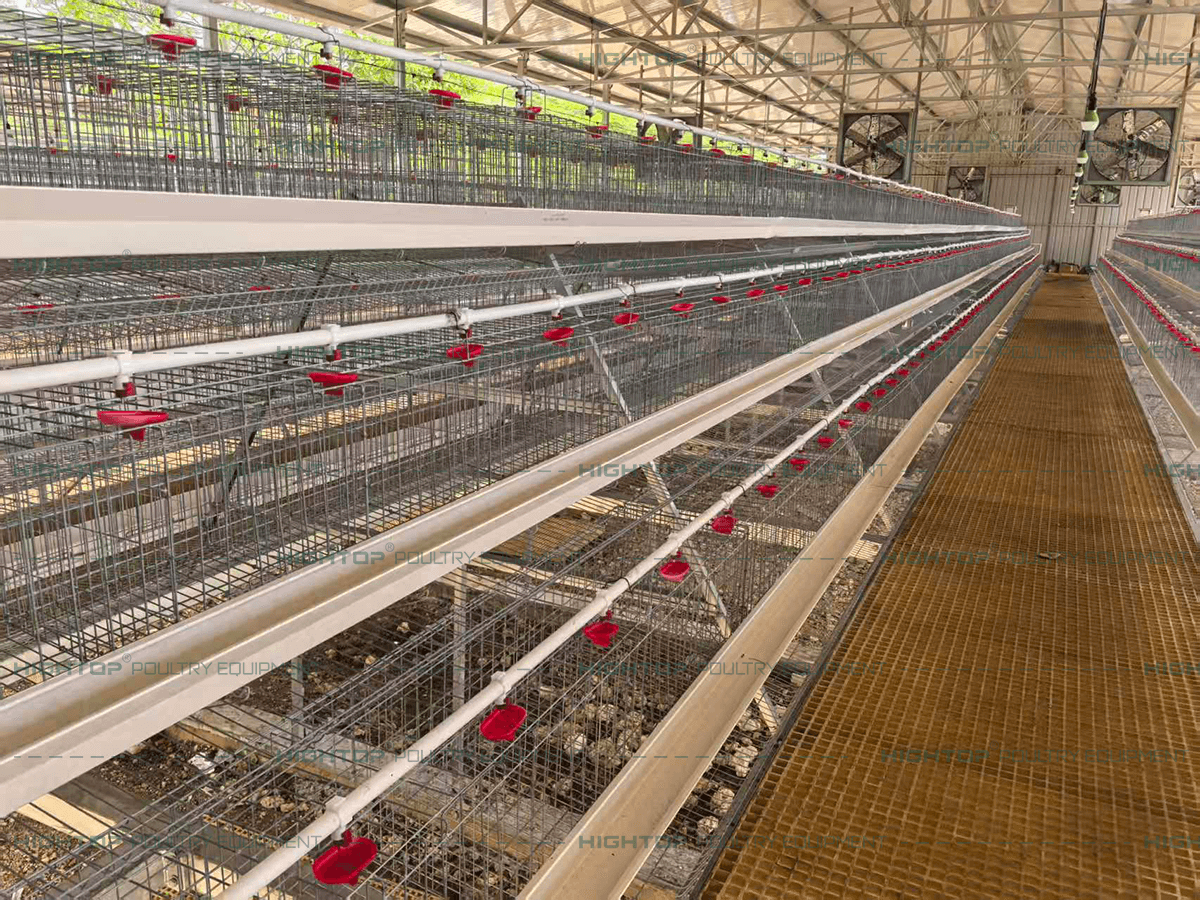

2.2 Cage System Layout

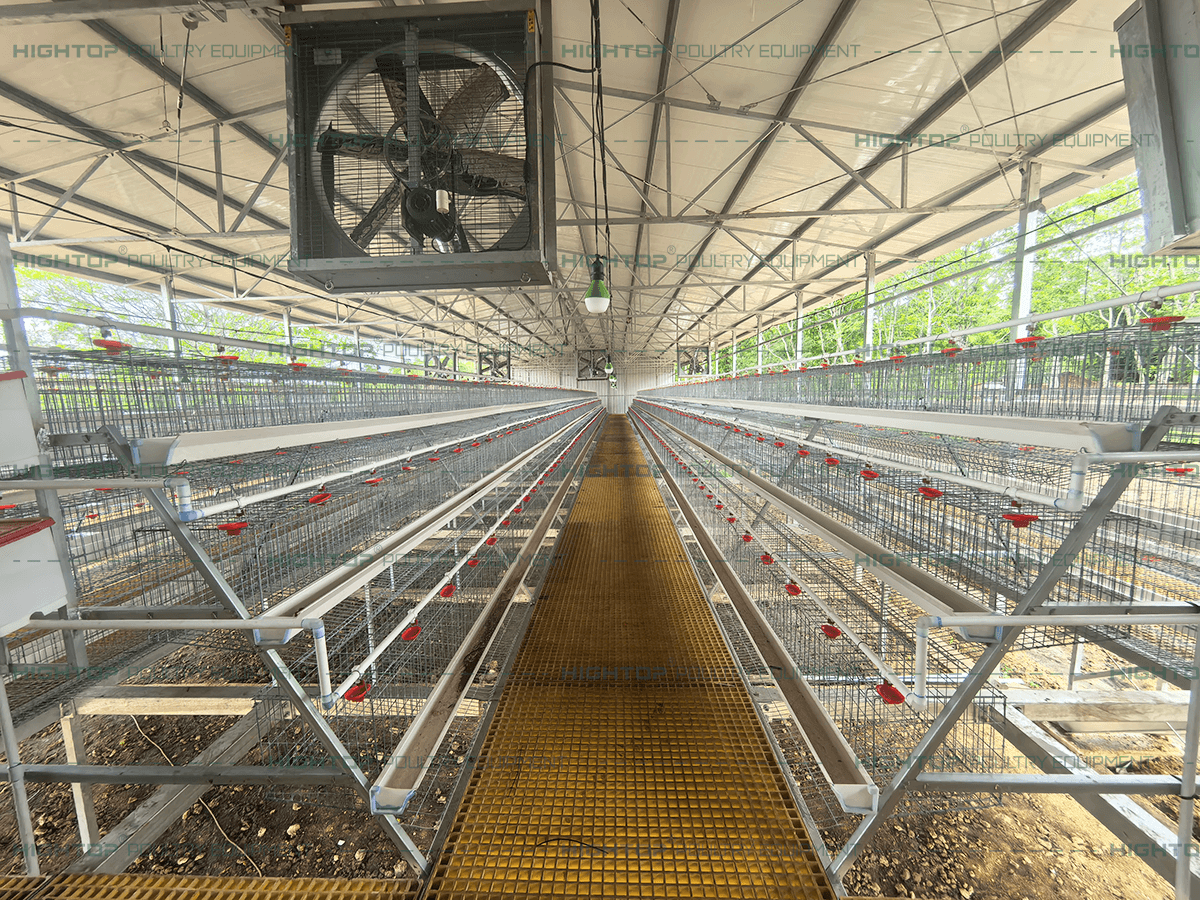

The project uses a 3-tier ordinary layer cage system arranged in three rows per house.

- Rows per house: 3

- Cage sets per row: 16

- Cage sets per house: 48

- Birds per cage set: 90

- Birds per house: 4,320

- Total birds in the project: 25,920

This layout ensures balanced stocking density and efficient use of available space, making it suitable for small and medium-scale layer farms.

2.3 Layer Cage Specifications

- Cage tiers: 3

- Cage size: 1.95 m × 0.38 m × 0.40 m (front height) × 0.35 m (back height)

- Nests per cage: 5

- Nest size: 39 × 38 cm

- Birds per door: 3

- Average area per bird: approximately 494 cm²

The cage system is designed to provide a stable and practical production environment while maintaining cost efficiency.

2.4 Production Parameters

- Rearing period: 16–80 weeks

- Suitable chicken weight: around 2.3 kg

For ordinary layer cage systems, the recommended farm scale is 2,000–20,000 birds, with a maximum of approximately 10,000 birds per building. This project falls within the optimal range for semi-automatic layer farming.

3. Equipment Configuration: Practical and Economical Solution

Unlike large-scale automated layer farms, this project adopts a simplified equipment configuration focused on reliability, affordability, and ease of operation.

3.1 Feeding System

The farm uses a semi-automatic feeding cart system rather than a fully automated feeding line.

Key advantages include:

- Faster feed distribution compared with manual feeding

- Reduced labor intensity

- Low equipment investment

- Easy operation and maintenance

The semi-automatic feeding cart represents a transitional solution between manual feeding and full automation, offering an excellent cost-performance ratio for small and medium farms.

3.2 Drinking System

- Standard nipple drinking lines

- Stable and hygienic water supply

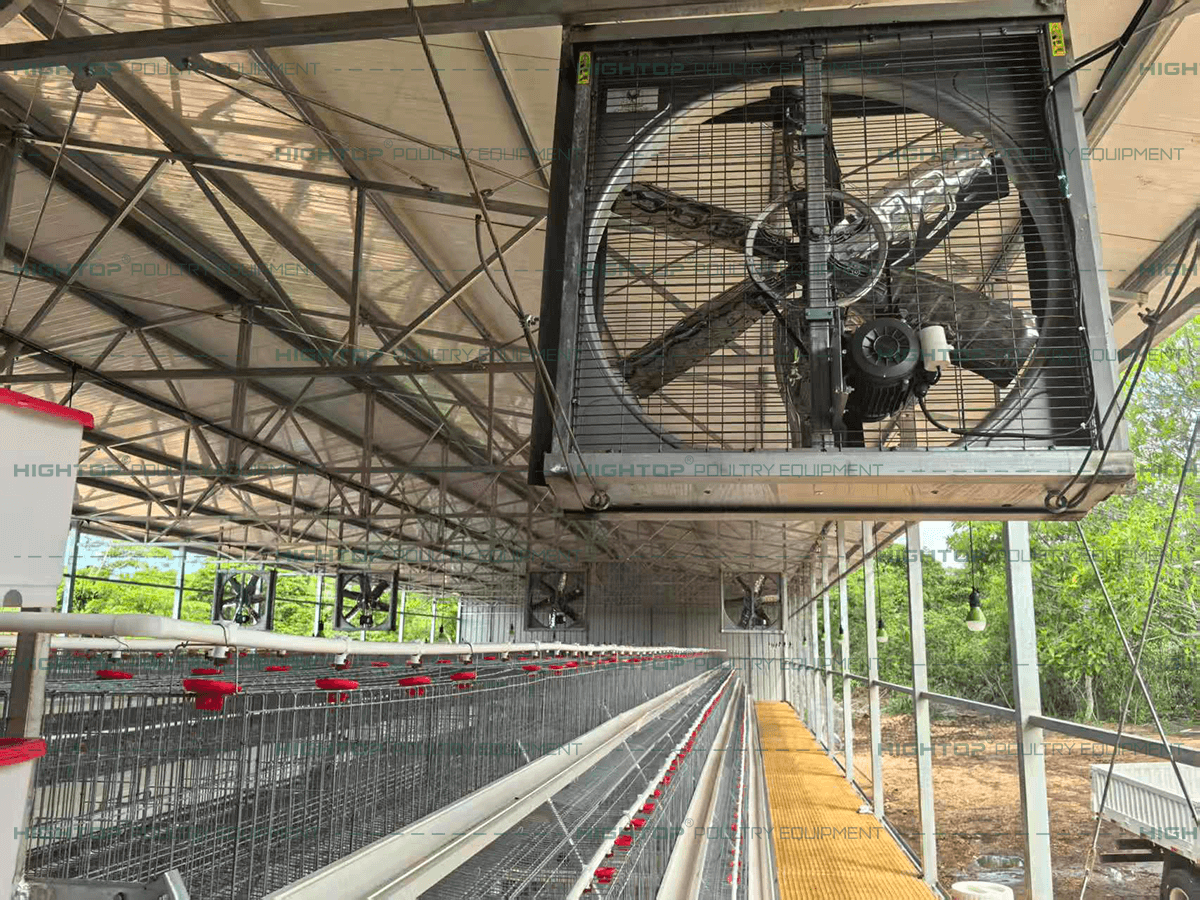

3.3 Supporting Equipment

The chicken house uses ventilation fans to enhance airflow and improve the internal environment.

Because the chicken house is elevated, manure naturally falls below the coop, eliminating the need for manure removal equipment. This design reduces equipment costs and simplifies daily management while maintaining hygiene.

4. Client Feedback and Operational Performance

After the farm was put into operation, the client reported significant improvements in production efficiency and management convenience.

4.1 Controlled Investment and Faster Payback

The client highlighted that the most important advantage of the project was its low investment cost.

Compared with fully automated layer cage systems, the total project investment was substantially reduced, allowing the client to:

- Start commercial egg production with limited capital

- Reduce financial risk

- Achieve a shorter payback period

This model is particularly suitable for developing poultry markets such as Papua New Guinea, Southeast Asia, and Latin America.

4.2 Stable Egg Production

Despite its simple configuration, the farm achieved stable production performance:

- Consistent egg output

- Uniform flock growth

- Acceptable mortality rate

- Reliable daily operation

The client confirmed that ordinary cages combined with semi-automatic feeding equipment were sufficient to meet commercial production requirements.

4.3 Improved Labor Efficiency

The semi-automatic feeding cart significantly improved feeding efficiency:

- Reduced manual workload

- Improved feeding speed and uniformity

- Simplified daily management

Although the system is not fully automated, it represents a major improvement over traditional manual feeding methods.

4.4 Flexibility for Future Expansion

The client also emphasized the flexibility of the system.

The farm can be upgraded gradually by:

- Adding more chicken houses

- Increasing cage tiers

- Upgrading to automated equipment in the future

This phased development approach aligns with the growth path of many small and medium poultry farms.

5. Technical Advantages of HIGHTOP Layer Cage System

This project demonstrates that ordinary layer cages can achieve high durability and performance when designed with advanced structural and material standards.

5.1 High-Strength Frame Structure

The cage frame adopts a U-shaped structure with 2 mm thickness and three-side forming. The cold roll forming process eliminates welding joints, resulting in a stronger and more stable structure.

- No welding parts, reducing structural weak points

- Higher mechanical strength and load-bearing capacity

- Improved durability and stability

The frame uses 275 g/m² zinc-coated steel sheets, the same material standard as the battery cage system, ensuring excellent corrosion resistance.

5.2 Smooth Mesh Surface

The cage mesh adopts an upgraded hot-dip galvanizing process with a smooth surface finish.

Key benefits:

- Smooth mesh surface prevents injuries to chicken feet

- Reduced stress and improved bird welfare

- Longer service life of cage components

5.3 Strong Cage Mesh

The cage mesh is made of Q235 steel wire with a yield strength greater than 600 N, ensuring high resistance to bending and deformation.

Additional features:

- 3 mm reinforcing wires used to hang the cage

- Enhanced structural stability under load

5.4 Cage Floor Mesh Connector

The upgraded cage design includes metal connectors for the cage floor mesh.

Advantages:

- Improved structural integrity of the cage floor

- Reduced vibration and deformation

- Higher load-bearing capacity

5.5 Optimized Cage Floor Mesh Design

The cage floor mesh is reinforced by adding extra wires to eliminate gaps.

Benefits:

- Reduced broken egg rate

- Improved egg rolling performance

- Enhanced overall cage durability

5.6 Reinforced Warp Wire Structure

All warp wires (longitudinal wires) are made of 3 mm reinforcing steel wire.

Key advantages:

- Strong resistance to bending

- Improved load-bearing performance

- Longer service life of the cage floor mesh

6. Conclusion: An Ideal Solution for Small and Medium Layer Farms

This layer farm project in Papua New Guinea demonstrates that a cost-effective cage system combined with a semi-automatic feeding cart can provide a practical pathway to commercial egg production.

By adopting an ordinary layer cage system with enhanced structural design, farmers can achieve:

- Low initial investment

- Stable production performance

- Improved management efficiency

- Long-term durability and reliability

For poultry producers in Papua New Guinea, Southeast Asia, and Central and South America, this solution represents an optimal balance between cost control and production efficiency.

Compared with fully automated layer cage systems used in large-scale farms, this system offers a realistic and scalable option for farmers seeking sustainable growth in the poultry industry.