Background and Objectives

The poultry industry in the Philippines has been expanding rapidly, with farmers increasingly seeking high-efficiency, automated solutions to overcome challenges such as labor shortages, high feed costs, and disease management. Traditional floor farming methods require more space, more manpower, and involve greater hygiene risks due to contact with manure and wet litter.

To address these challenges, the client chose HIGHTOP Poultry Equipment to provide a chain-type automated broiler cage system, integrating full automation from feeding and watering to manure cleaning and broiler harvesting.

The goal of this project was to:

-

Increase broiler rearing density per unit area.

-

Reduce manual labor through automation.

-

Improve feed conversion efficiency and survival rates.

-

Enhance environmental control and overall productivity.

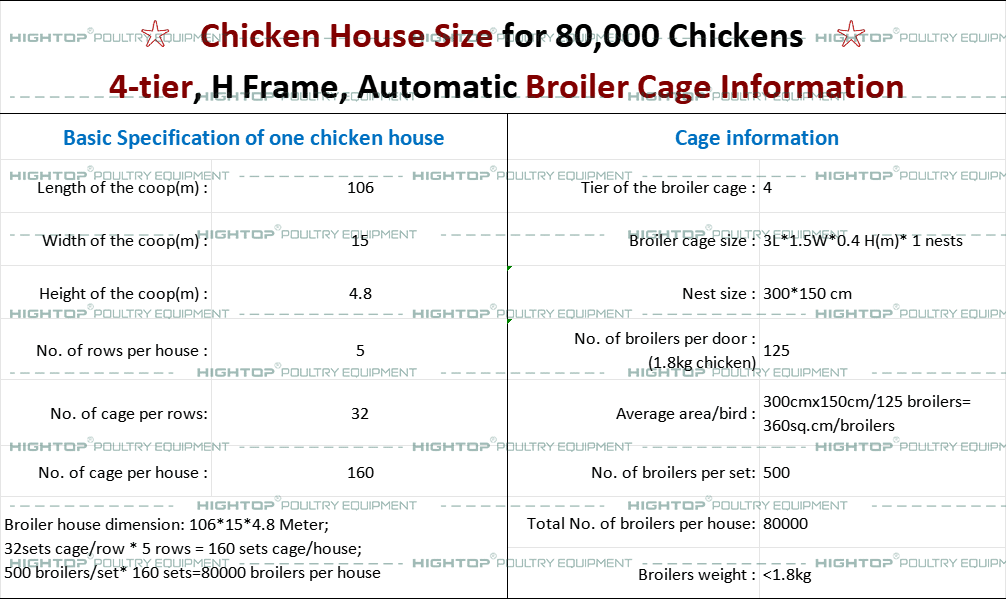

Project Overview

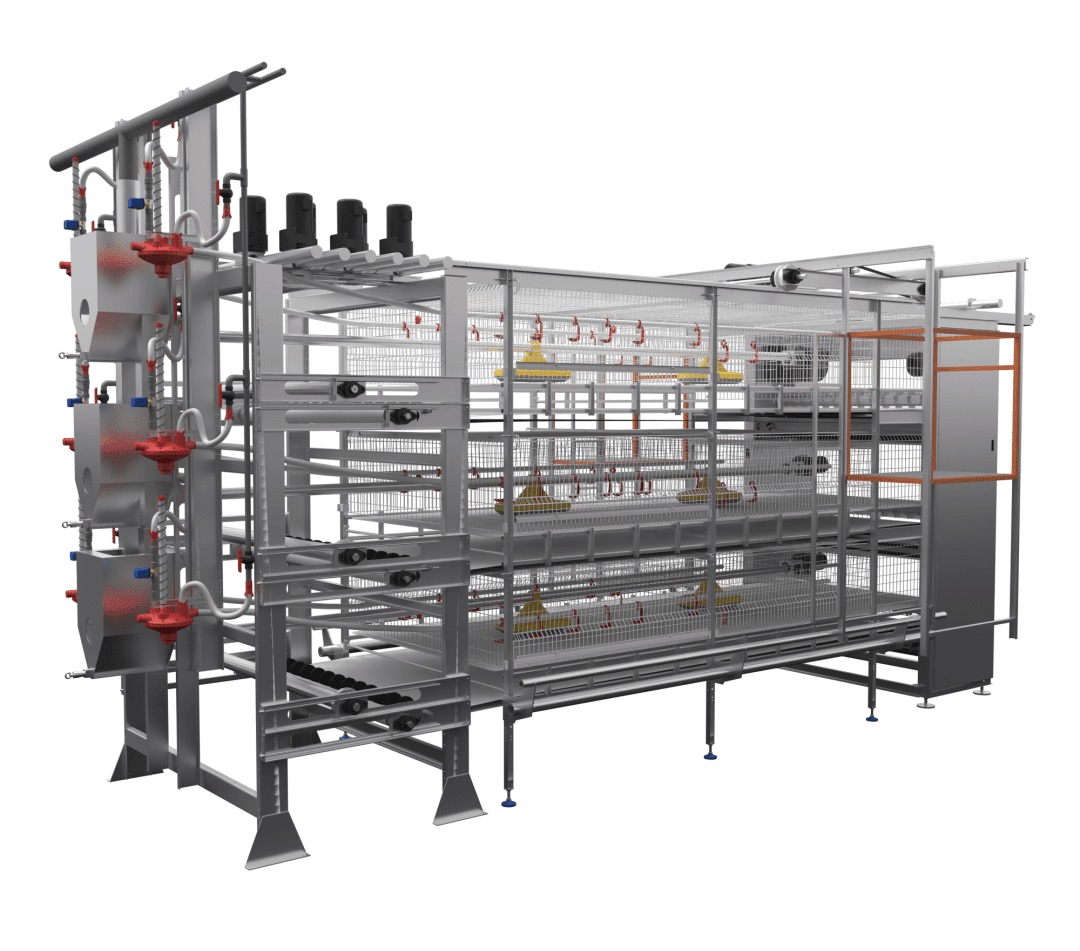

The project is located in the Philippines and features a fully automated H-type broiler cage system. The chicken house is designed for intensive and efficient broiler farming, using the latest chain-type automatic harvesting technology.

Key project details:

-

Chicken house dimensions: 106 m (length) × 15 m (width) × 4.8 m (height)

-

Cage system: H-type chain-type automated broiler cage system

-

Configuration: 5 rows × 4 tiers

-

Total cage sets: 160 (32 cages per row)

-

Capacity per cage set: 500 broilers

-

Total capacity: 80,000 broilers

-

Average broiler weight: <1.8 kg

Each cage measures 3 m in length, 1.5 m in width, and 0.4 m in height, with one nest per unit. The design optimizes space utilization, air circulation, and feed efficiency, ensuring every broiler has adequate space and a clean, comfortable growing environment.

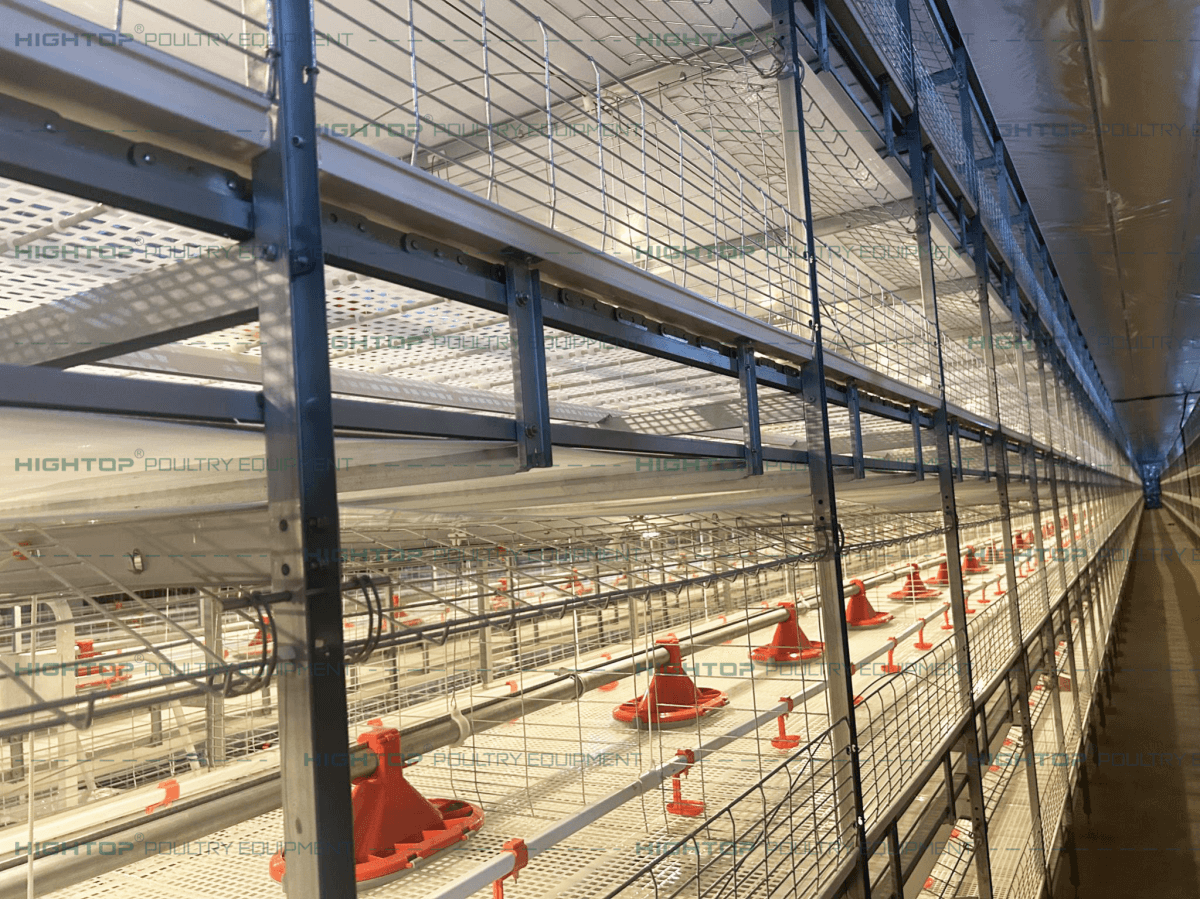

System Design and Structure

The H-type cage system was selected due to its vertical design, which maximizes space and promotes high-density rearing. The structure is made of Q235 carbon steel with hot-dip galvanized coating (275 gsm), ensuring corrosion resistance, long-term durability, and a service life of 15–20 years.

Each cage includes:

-

Chain-type automatic harvesting system

-

Automatic feeding system

-

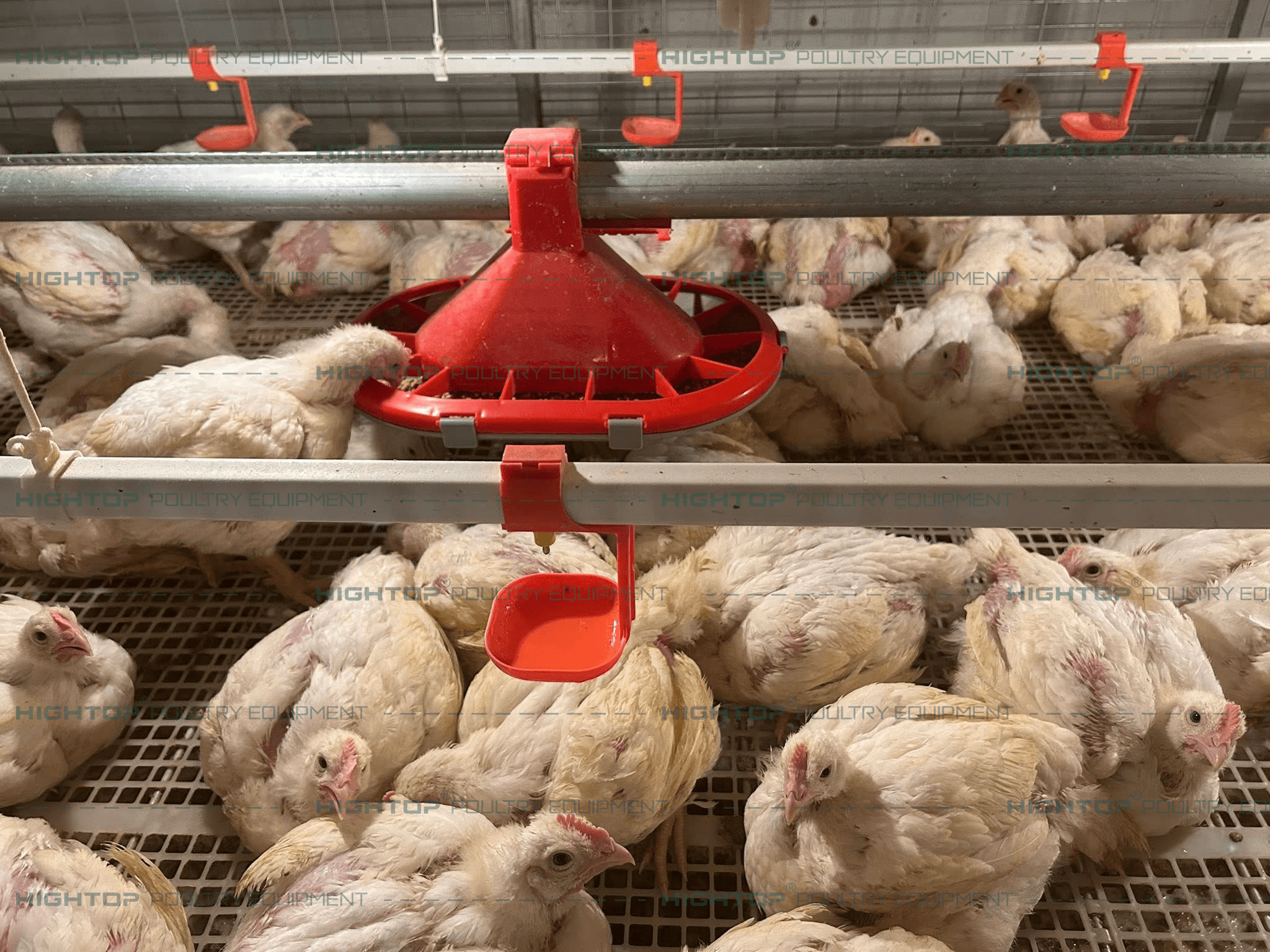

Automatic nipple drinking system

-

Automatic manure cleaning belt (1.2 mm PP belt)

-

Ventilation and cooling system

-

Environmental control system

The layout of five rows and four tiers allows optimal use of vertical space within the 106-meter-long chicken house, achieving efficient ventilation and uniform temperature distribution.

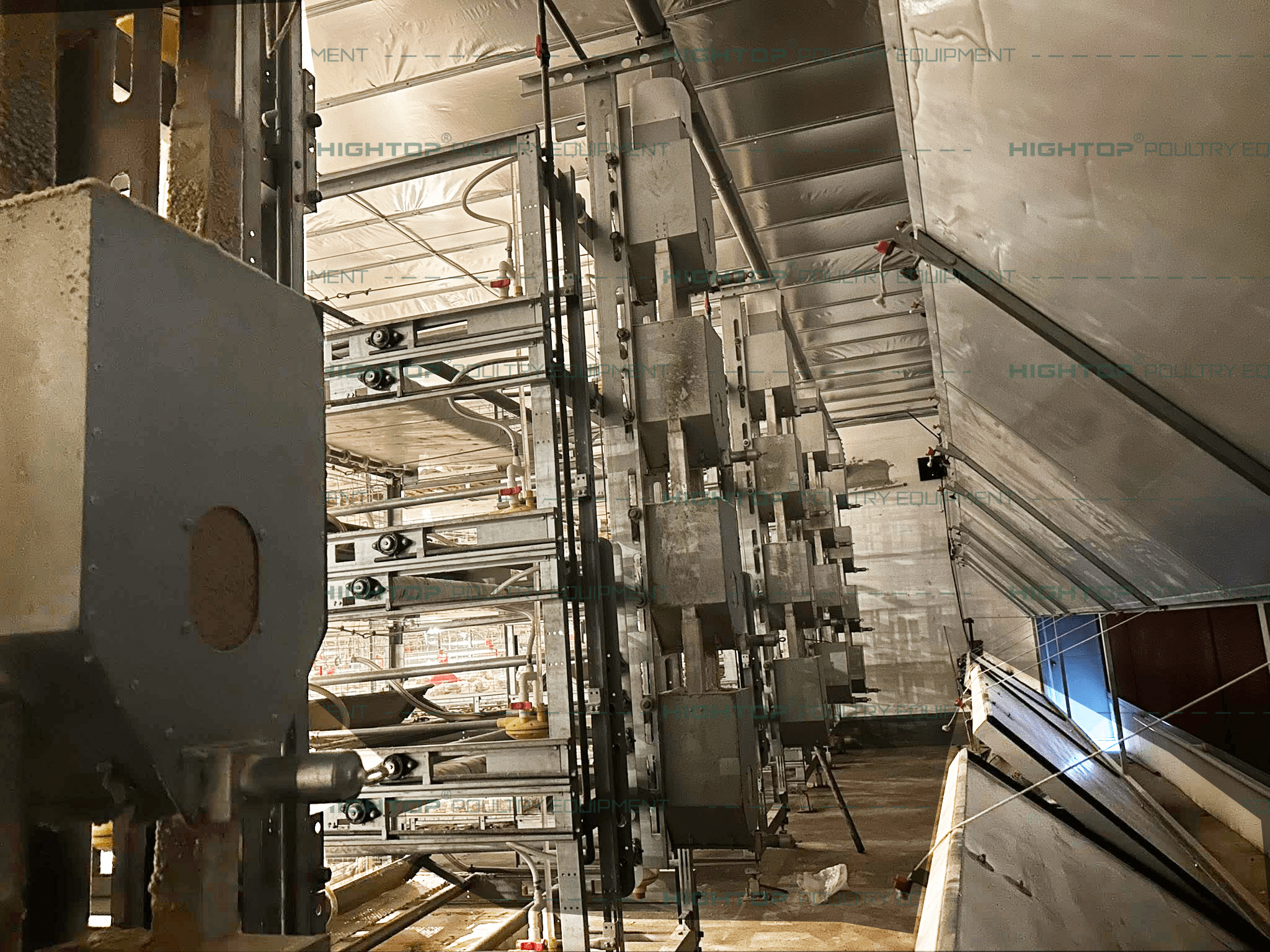

Chain-Type Automated Harvesting System

One of the standout features of this project is the chain-type automated harvesting system, developed to simplify the traditionally labor-intensive process of catching and transporting broilers.

In this system, the cages are equipped with a chain-driven mechanism that gently moves the birds toward the collection end. Once the chain is activated, the broilers are automatically transported onto the collection belt and moved outside the house for packaging and transport.

Key benefits of the chain-type harvesting system include:

-

Reduced labor costs: Eliminates the need for manual catching, which usually requires large labor teams.

-

Improved efficiency: Speeds up harvesting, allowing the entire house to be cleared in a fraction of the time compared to traditional methods.

-

Reduced bird stress and injury: Automated handling minimizes contact and prevents bruising or mortality due to rough handling.

-

Clean and hygienic process: The system keeps broilers separate from manure belts, maintaining better hygiene and meat quality.

This innovation not only saves time and manpower but also ensures a more humane and efficient broiler collection process.

Customer Feedback

The client reported high satisfaction with the overall system performance, emphasizing how HIGHTOP’s technology made daily operations more efficient and predictable. Farmers noted that:

-

The chain-type harvesting system “saved days of labor” during collection.

-

The environment remained “clean, odor-free, and easy to manage.”

These outcomes have encouraged the client to consider expanding with additional automated houses in the near future.

Advantages of HIGHTOP’s H-Type Broiler Cage System

HIGHTOP’s H-type automated broiler cage system is designed to provide high efficiency, hygiene, and long-term profitability for poultry farms. Below are the key advantages observed in this project:

1. High Rearing Density and Space Efficiency

The vertical four-tier design allows farmers to raise up to 80,000 broilers in a single 106×15 m house, significantly increasing production per square meter. Compared with traditional floor rearing, the cage system can increase capacity by 50–100% on the same land area.

2. Improved Feed Conversion Ratio (FCR)

Broilers raised in cages consume less energy since their movement is limited. The controlled feeding system minimizes waste, ensuring that every bird receives adequate feed. The result is a lower feed-to-meat ratio, improving profitability per batch.

3. Healthier Environment and Lower Mortality

Manure is removed automatically through the belt cleaning system, preventing contact between chickens and waste. This reduces ammonia levels and harmful gases inside the shed, leading to healthier birds and a lower incidence of disease. The average survival rate exceeds 98%, with significantly reduced medication costs.

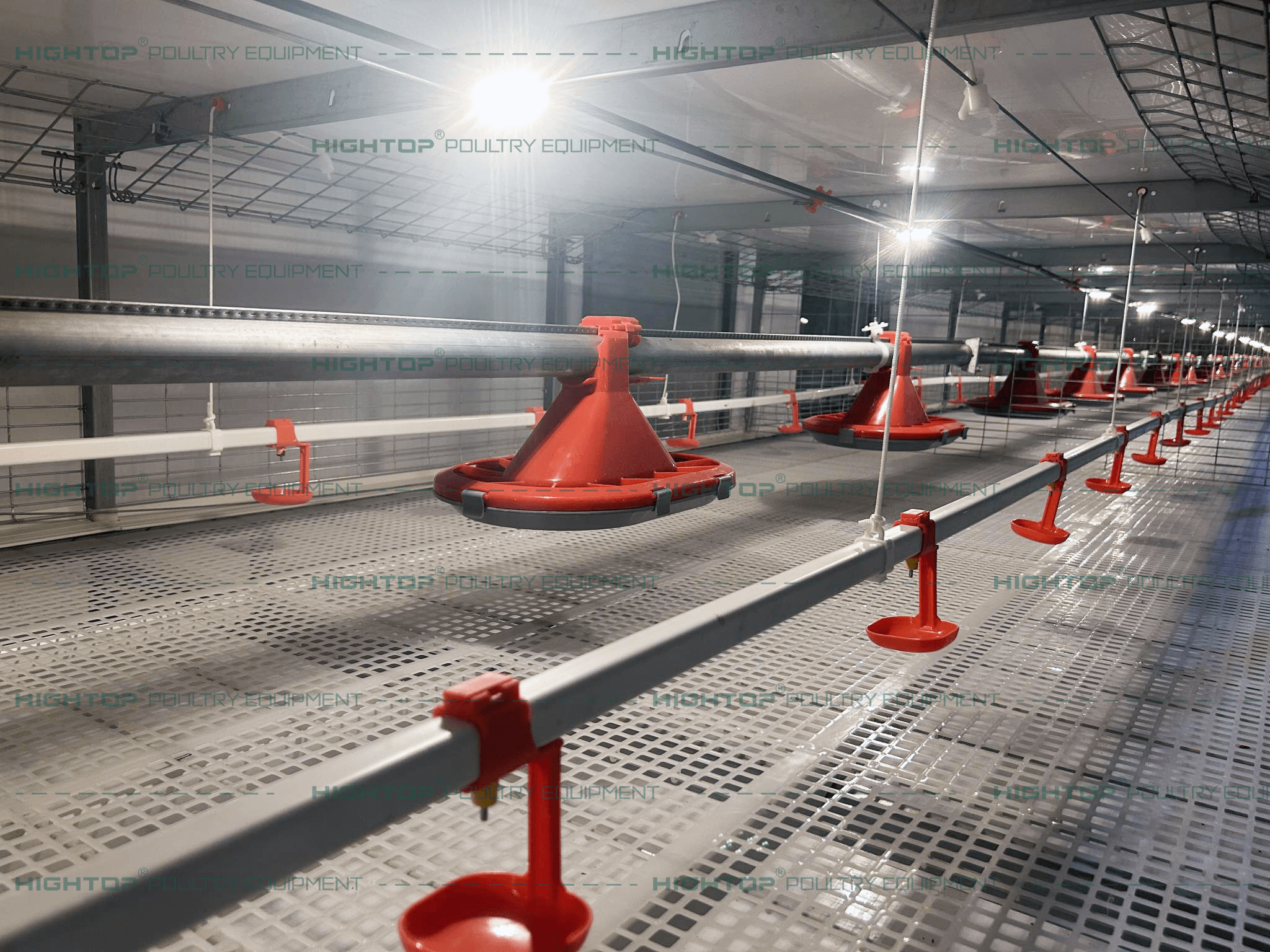

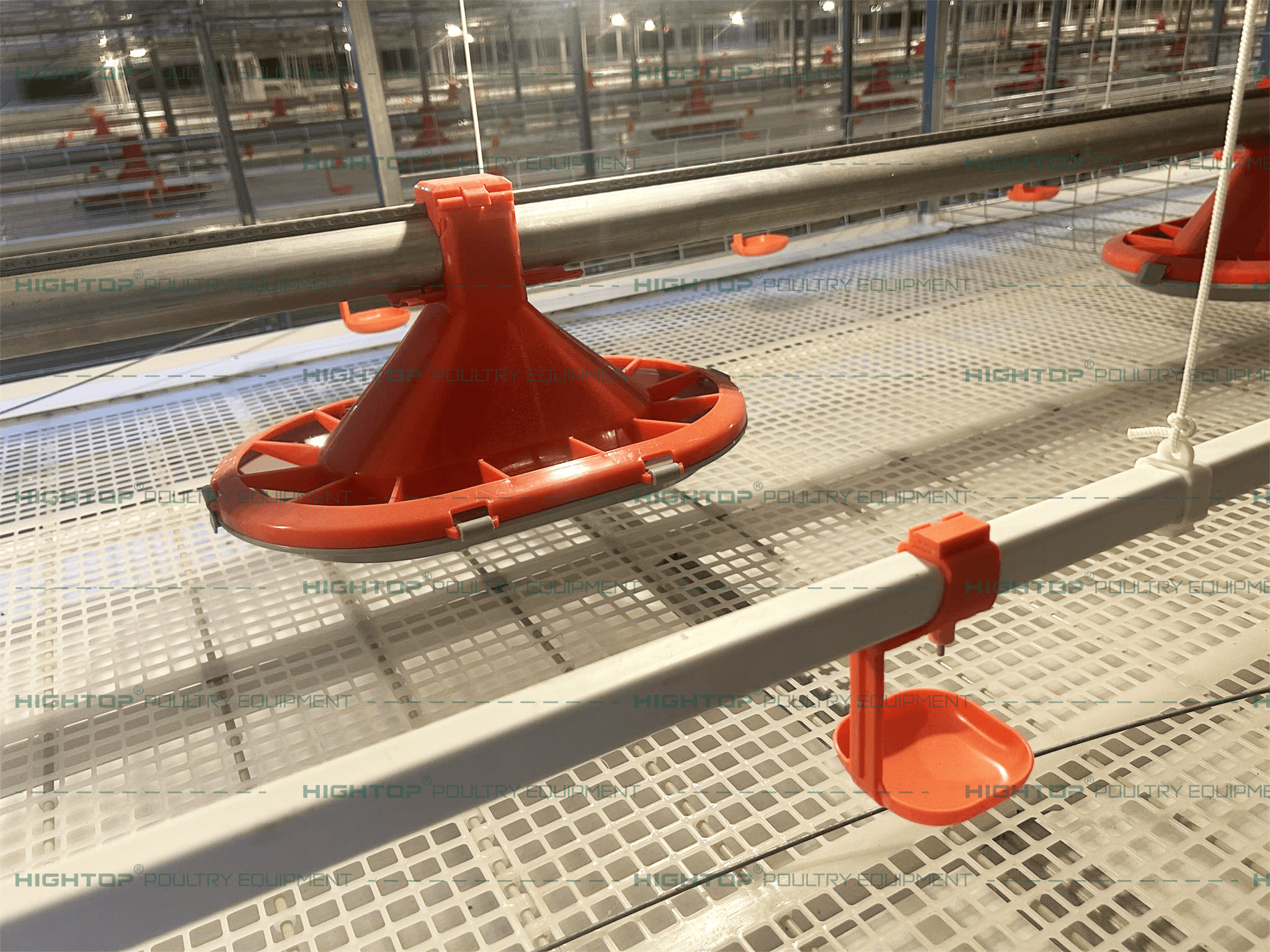

4. Automated Feeding and Watering Systems

The automatic feeding system ensures uniform distribution of feed across all tiers, reducing competition among broilers. The nipple drinking system with water pressure regulation provides constant, clean water supply, improving bird hydration and growth uniformity.

5. Efficient Manure Cleaning System

The 1.2 mm PP manure belt runs below each tier, automatically collecting and removing waste at regular intervals. This keeps the environment clean, prevents fly breeding, and reduces labor requirements.

6. Environmental Control and Energy Savings

The system is equipped with ventilation fans, cooling pads, and environmental control units, which automatically regulate temperature and humidity. This ensures the chickens remain comfortable throughout the rearing cycle, regardless of outdoor weather conditions.

7. Durable, Long-Lasting Materials

All structural components are made from Q235 hot-dip galvanized steel, offering strong corrosion resistance and structural stability. The average service life of the equipment is 15–20 years, ensuring a low cost per year of operation.

8. Reduced Labor and Maintenance Costs

Full automation—from feeding and watering to manure cleaning and harvesting—allows the farm to operate with minimal labor. The system’s modular design simplifies maintenance and makes it easy to expand in the future.

Performance and Results

After installation and several production cycles, the project achieved excellent performance indicators:

-

Average market weight: <1.8 kg per broiler at 42 days

-

Average survival rate: 98.5%

-

Feed-to-meat ratio: 1.62:1

-

Labor reduction: Over 60% compared with floor rearing

-

Manure removal frequency: Once daily, reducing odor and disease risk

-

Harvesting efficiency: One person can operate the automatic collection system, clearing the entire house in a few hours

These results demonstrate how modern automation significantly improves operational efficiency, bird welfare, and profitability for commercial broiler farms.

Economic Benefits

The switch to a chain-type automated broiler cage system offers multiple economic advantages:

-

Faster payback period: With improved efficiency and reduced losses, return on investment can be achieved in as little as three years.

-

Reduced feed waste: Up to 5% feed savings per batch through precise feeding.

-

Lower mortality: Healthier environment leads to fewer losses, directly boosting profit margins.

-

Labor savings: Automation cuts manpower requirements by more than half, lowering operational costs.

In total, this system allows for higher output with lower cost, providing long-term stability and profitability.

Summarize

The Philippines chain-type automated broiler cage project represents a successful model for modern poultry farming in tropical regions. By integrating automation, smart design, and durable materials, HIGHTOP Poultry Equipment has helped its client achieve higher productivity, improved bird welfare, and reduced operational costs.

As global poultry demand continues to rise, projects like this demonstrate how technology can make broiler production more sustainable and profitable. With its chain-type automated harvesting system, robust H-type cages, and comprehensive environmental control, HIGHTOP Poultry Equipment continues to lead the transformation of poultry farming into a smarter, cleaner, and more efficient industry.