Case Study: 88,800 Broilers Raised in Manual Harvesting Broiler Cage System – Philippines, 2025

Project Overview

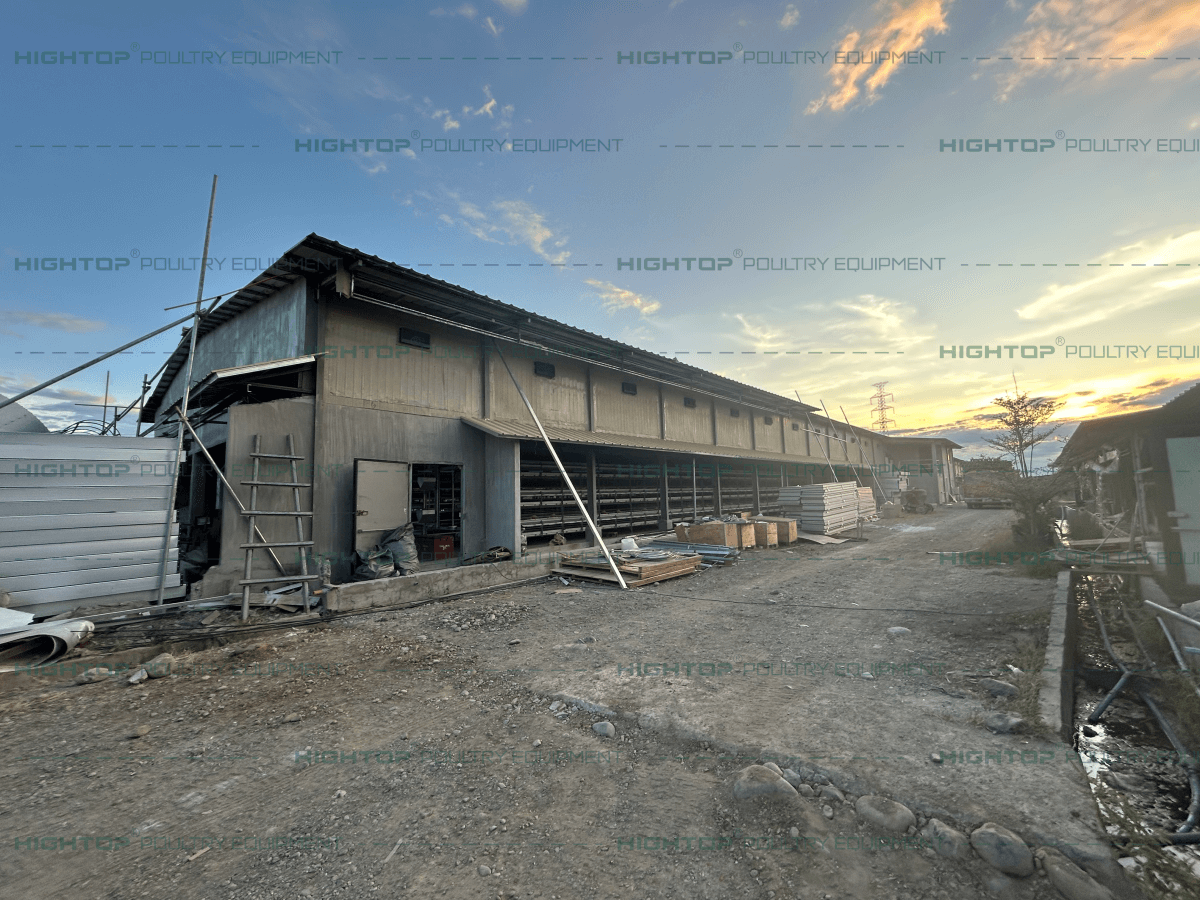

In 2025, a significant poultry farming project was completed in the Philippines featuring a modernized approach to broiler rearing. The project involved the construction of a large-scale manual harvesting broiler cage system, capable of housing 88,800 broilers per chicken house.

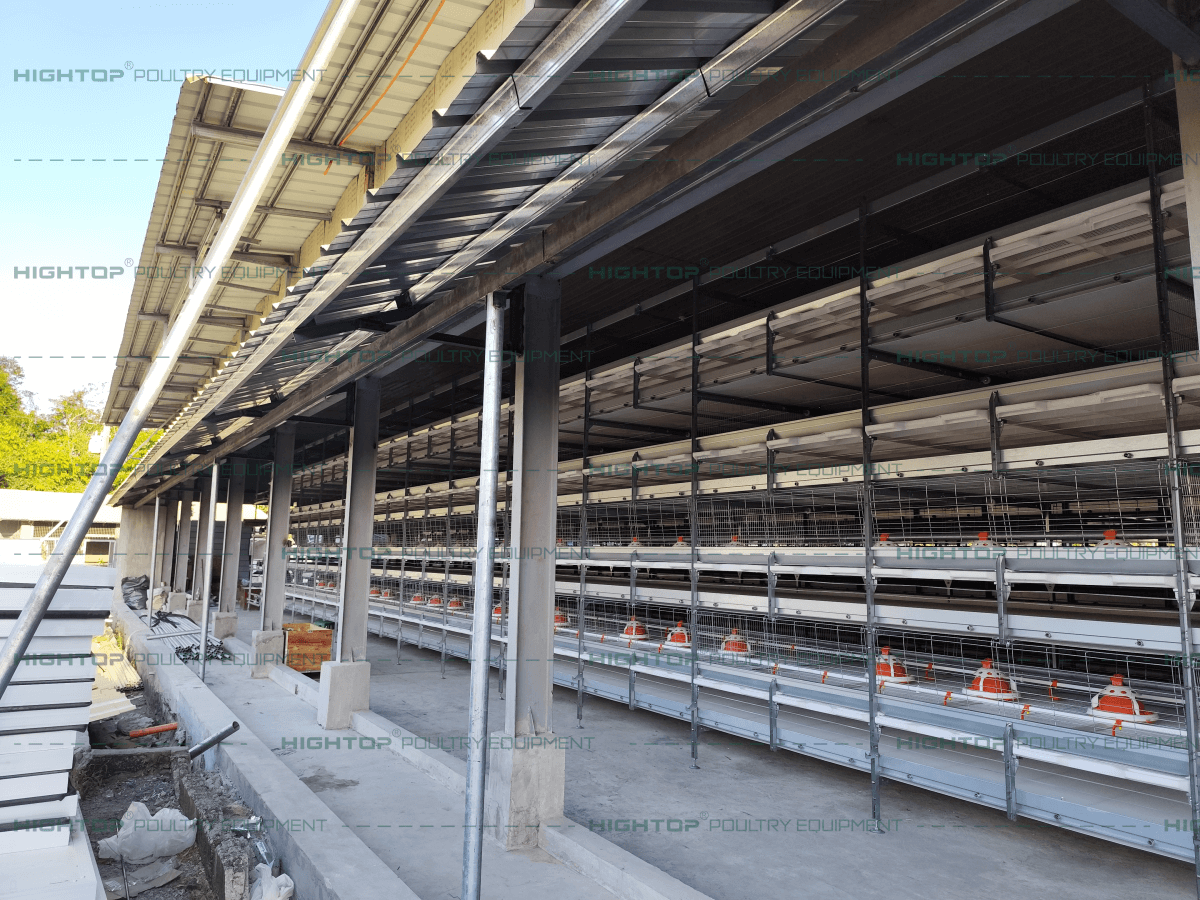

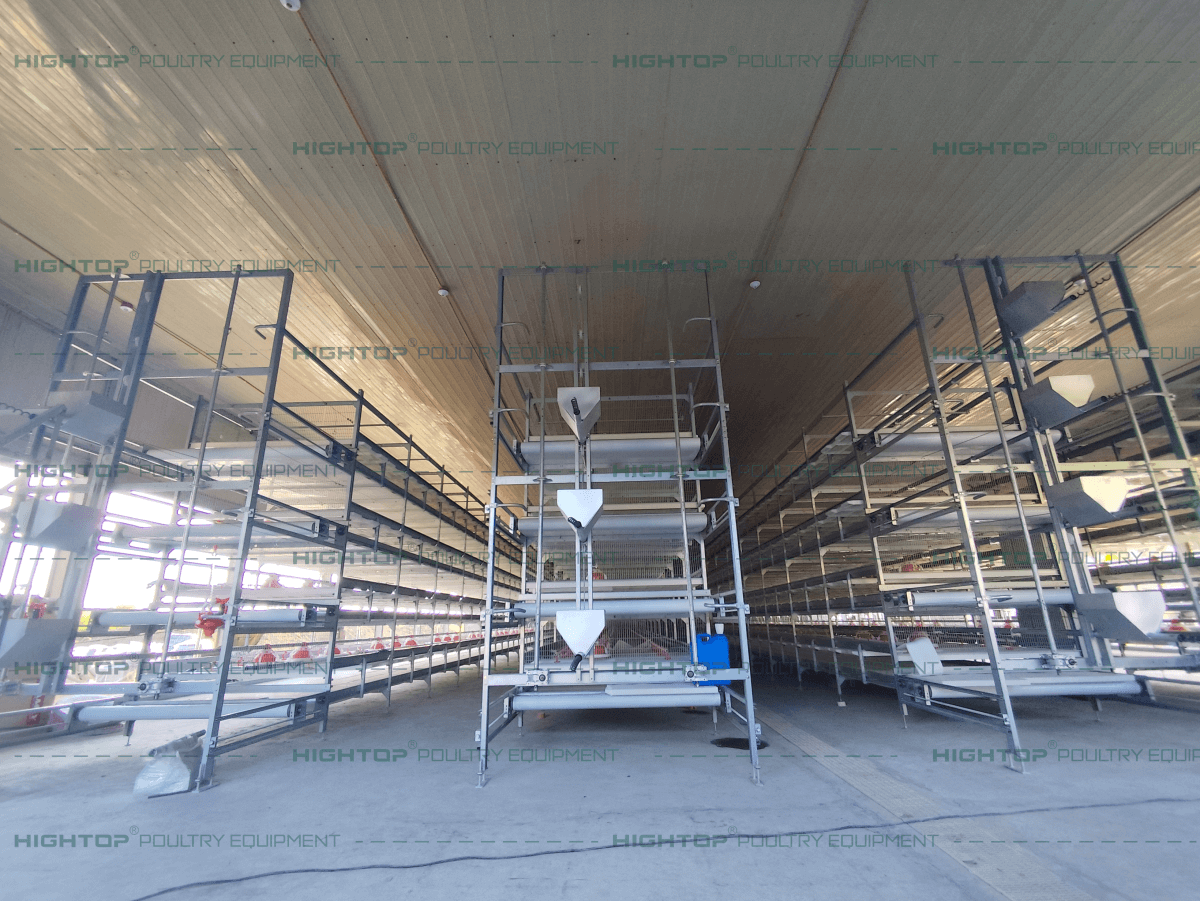

Each chicken house features a 4-row layout, utilizing 4-layer pull-out slatted broiler cages, which are designed to maximize space utilization while ensuring optimal bird welfare. The chicken houses measure 120 meters in length, 16 meters in width, and 5 meters in height, allowing for optimized ventilation and workflow.

This project is part of the growing trend in the Philippines to adopt efficient, semi-automated systems that boost productivity without compromising on animal handling and health.

Product Highlight: Pull-Out Slatted Broiler Cage System

The featured product in this project is HIGHTOP 4-layer pull-out slatted broiler cage, which is tailored for medium to large-scale broiler farms aiming to modernize operations with controlled investment.

This system is part of a broader range of automated broiler cages offered by HIGHTOP, including pull-out slatted types and new chain-type systems. Both designs integrate:

-

Automatic feeding

-

Automated manure cleaning

-

Innovative chicken collection solutions

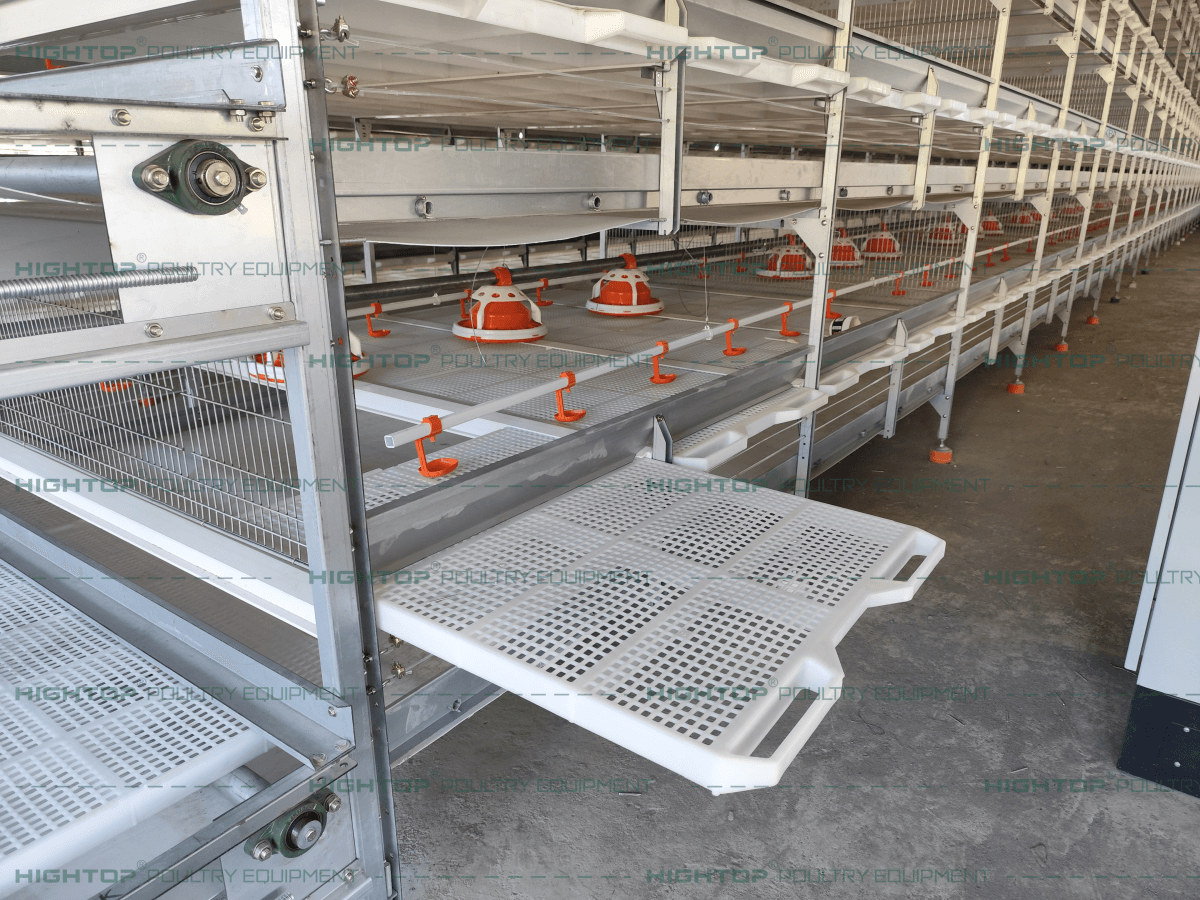

In the pull-out slatted system, each cage contains a removable tray. During harvesting, the tray is gently pulled out, allowing chickens to drop safely onto a moving manure belt beneath them. This belt transports the chickens to the rear end of the row, where a horizontal chicken collector lifts them from the system and places them onto a central round table.

This collection method simplifies harvesting and drastically reduces bird injury caused by stress or rough manual handling. Farm workers then easily collect birds from the table for transport or processing, increasing the efficiency of the broiler marketing process.

Why We Recommend HIGHTOP’s Pull-Out Broiler Cage System

Key Advantages:

-

Faster Chicken Collection: Traditional cage-by-cage harvesting is slow and labor-intensive. The pull-out system streamlines the process, reducing harvesting time and human labor needs.

-

Reduced Injury Rate: Chickens move smoothly through the system with minimal physical contact, significantly lowering the chances of fractures, wing damage, or bruising — all of which can impact product quality and welfare scores.

-

Improved Labor Efficiency: With the round table system, fewer workers are needed, and collection can be done more systematically and hygienically.

-

Clean and Organized Environment: The manure belt not only aids in collecting chickens but also supports automatic manure removal, helping maintain a cleaner chicken house and reducing the risk of disease spread.

-

Scalable and Suitable for Various Farm Sizes: While this case features nearly 90,000 birds, the pull-out system is modular and can be adapted for farms of different scales.

This Philippine project is a model for how medium to large-scale poultry farms can adopt semi-automated cage systems to meet growing market demands for efficient and humane broiler production. The HIGHTOP pull-out slatted broiler cage system proves to be a game-changer, balancing operational efficiency, animal welfare, and economic returns.

With modern challenges such as labor shortages, rising production costs, and stricter welfare regulations, solutions like this provide a forward-looking path for poultry farmers. Whether you’re planning a new farm or upgrading an existing one, HIGHTOP’s cage systems offer a smart investment into the future of sustainable broiler farming.

Contact us today to learn more or to customize a system for your poultry project.