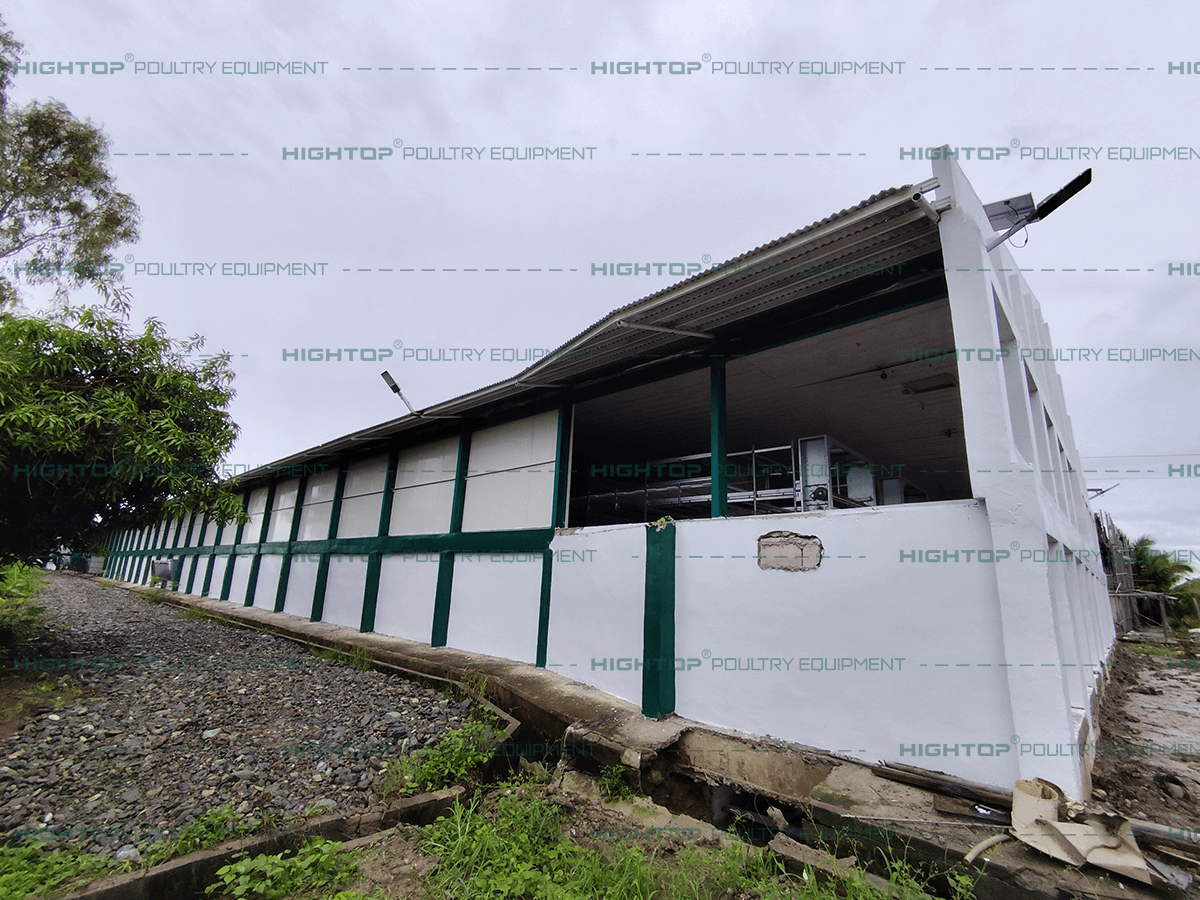

Case Study: Conversion of a Floor-Type Broiler Farm to a Pull-Out Slat Cage System with EC Fan Ventilation in the Philippines

1. Project Background and Client Challenges

This project is located in the Philippines, a country with a hot, humid tropical climate, where broiler production faces continuous challenges related to heat stress, ammonia accumulation, fly control, and rising labor and energy costs.

The client originally operated a free-range broiler house, with the following parameters:

- Building size: 450 ft (L) × 52 ft (W) × 7 ft (H)

- Stocking capacity: 40,000 broilers

- Production model: Floor rearing on litter

Although the floor system had been used for years, the client encountered increasing operational limitations:

- Limited stocking density and low space utilization

- High ammonia concentration and fly infestation

- Heavy labor requirements for litter management and bird harvesting

- High electricity costs due to inefficient ventilation fans

- Difficulty maintaining stable temperature and air quality during hot seasons

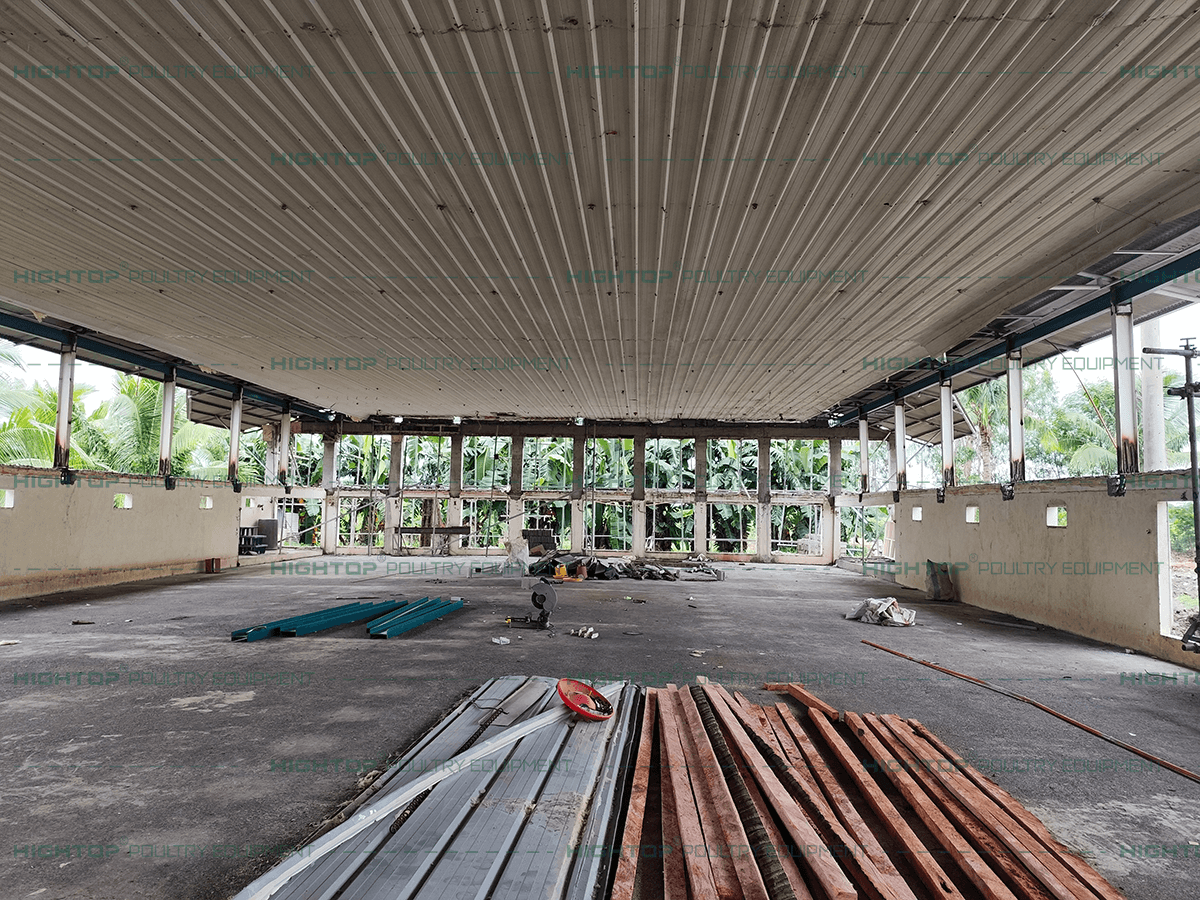

With rising demand for poultry meat and increasing pressure to improve efficiency, the client decided to upgrade and expand production capacity within the same footprint, rather than acquiring additional land.

After multiple technical discussions and on-site assessments, the final decision was made to convert the existing floor house into a fully enclosed, pull-out slat-type broiler cage system, supplied by HIGHTOP Poultry Equipment.

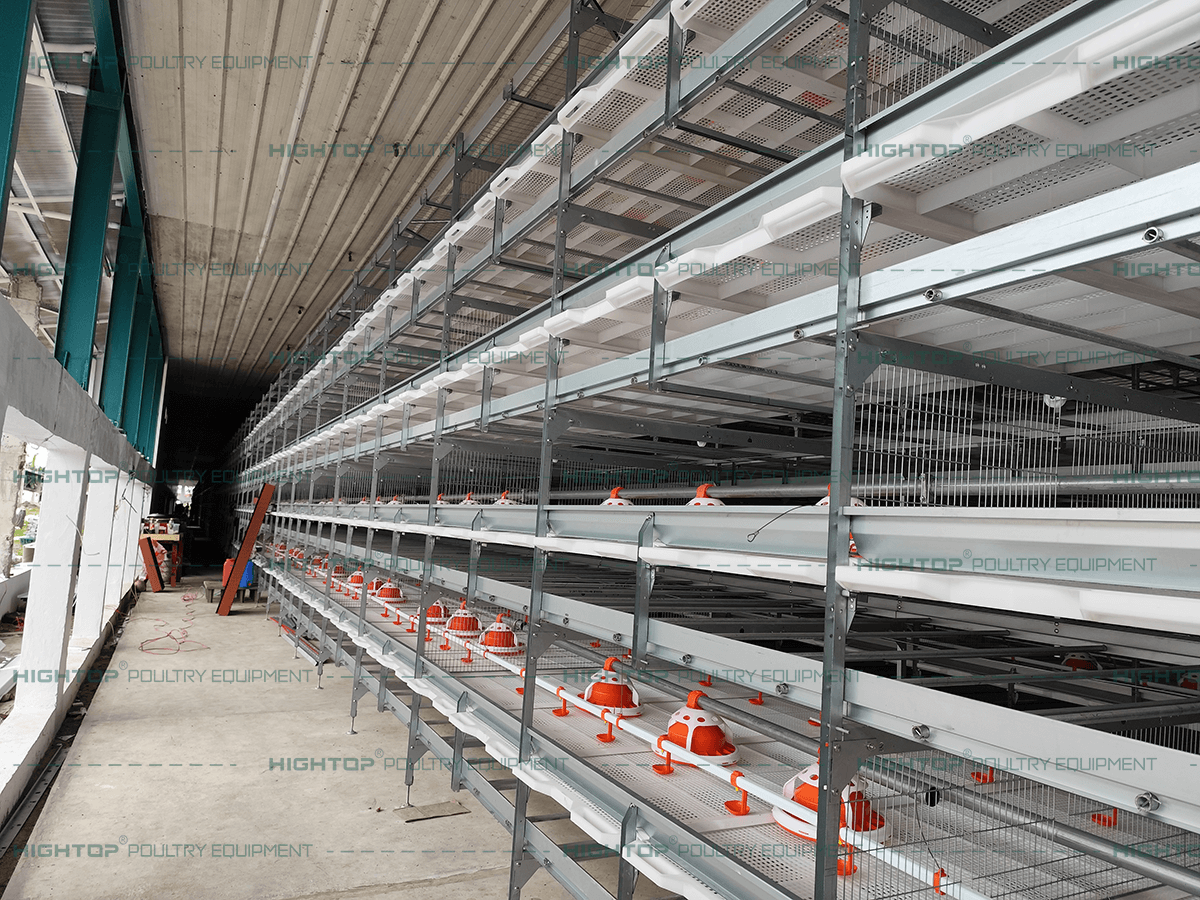

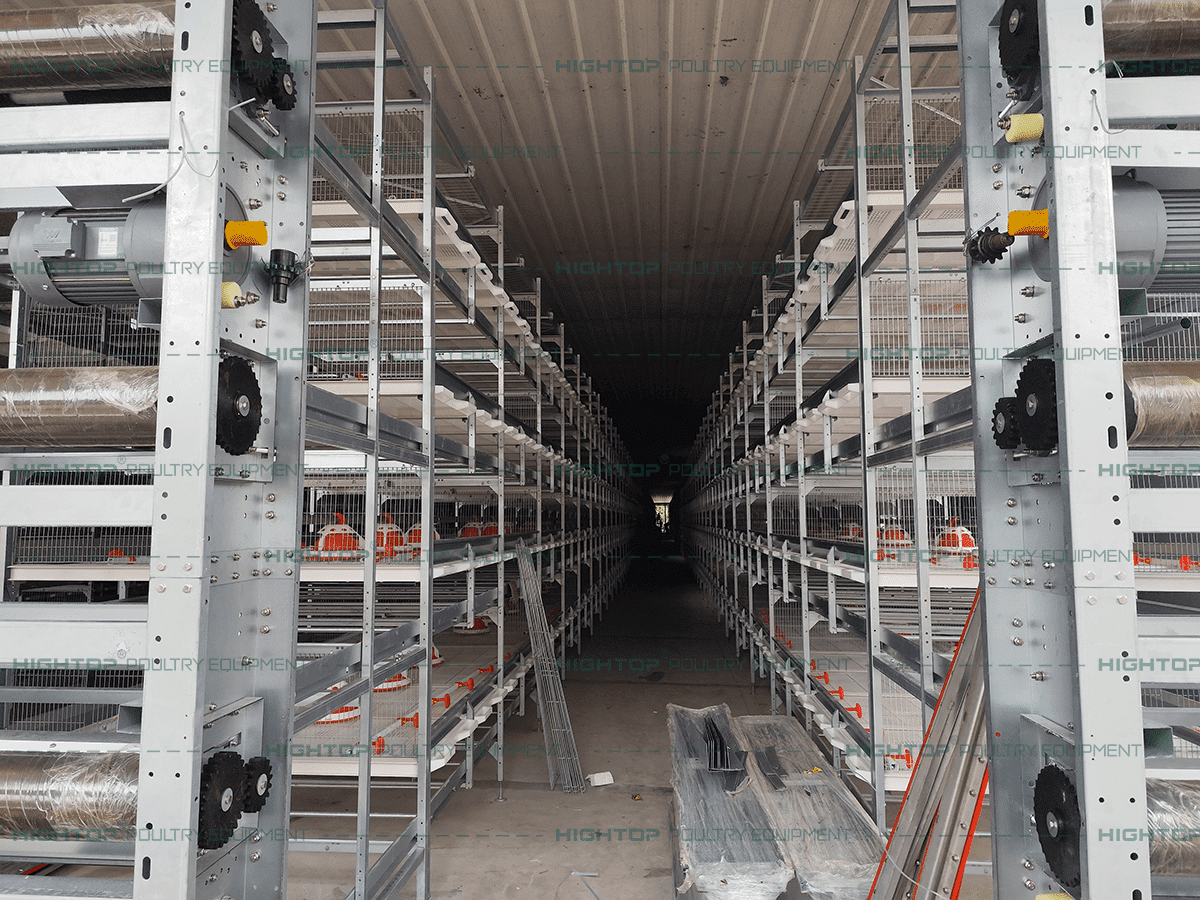

2. Upgrade Overview: From Floor System to Multi-Tier Cage System

After conversion, the new broiler house parameters became:

-

Building size:

-

450 ft (L) × 52 ft (W) × 14.8 ft (H)

-

Metric equivalent: 137 m (L) × 15.9 m (W) × 4.3 m (H)

-

-

Broiler capacity:

-

Increased from 40,000 birds to 90,000 birds

-

Average market weight: 1.8 kg per bird

-

This upgrade achieved a more than twofold increase in capacity, without expanding the building length or width. The key improvement was the transition from a floor-based system to a pull-out slat broiler cage system, allowing vertical space utilization and controlled environmental management.

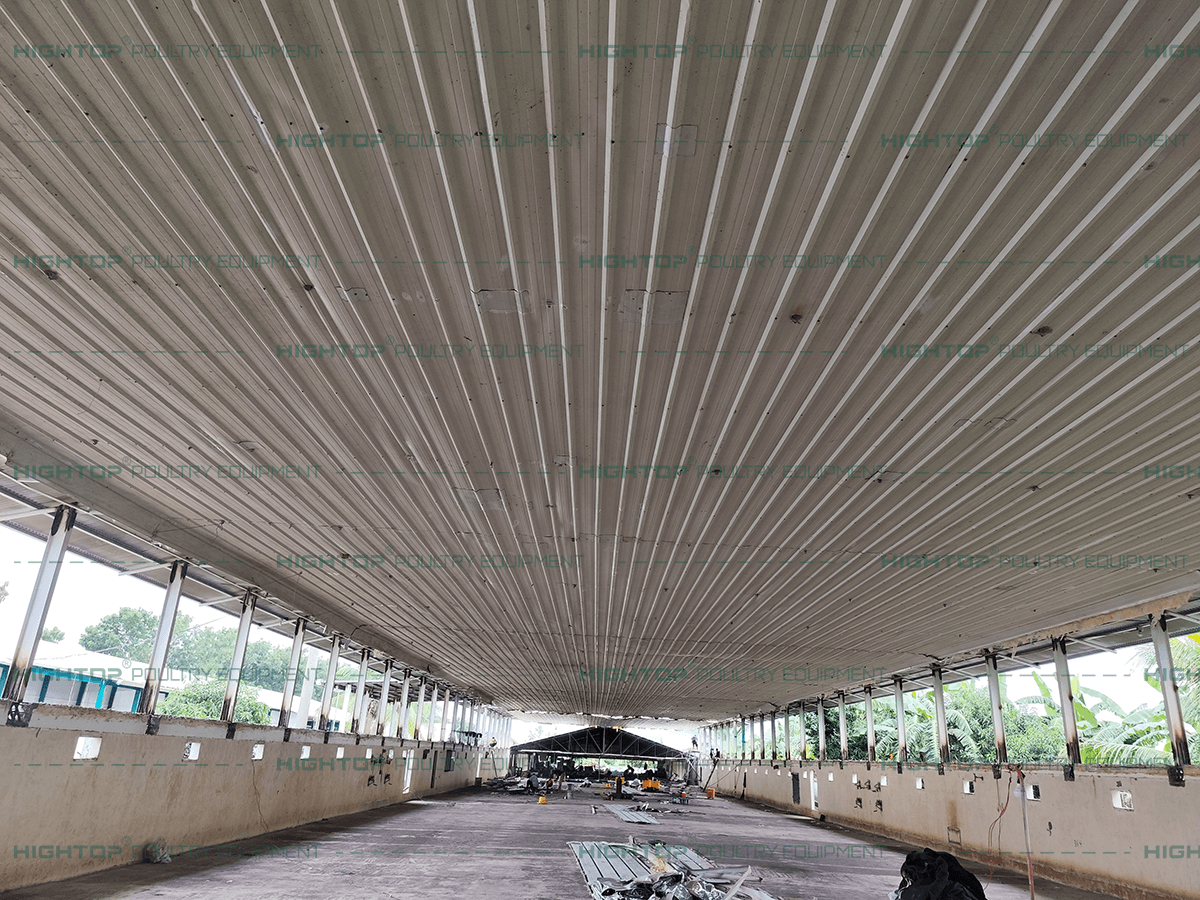

3. Enclosed Chicken House Design and Equipment Configuration

To support the higher stocking density and ensure stable performance, HIGHTOP Poultry Equipment provided a fully integrated enclosed broiler house solution, including the following major systems:

Feeding and Watering Systems

- Automatic pan feeding lines for uniform feed distribution

- Nipple drinking lines with drip cups to reduce water waste

Environmental Control and Ventilation

- EC fans (electronically commutated fans)

- Circulation fans and ceiling fans

- Cooling pads with air deflectors

- Air-inlet windows for controlled airflow

- Gas heaters for brooding and temperature stabilization

Waste Handling and Harvesting

- Automatic manure cleaning system

- Pull-out slat bird harvesting system, enabling fast and low-stress harvesting

Feed Storage

-

Two outdoor silos, ensuring stable feed supply and reducing labor intensity

This configuration was specifically designed to address the Philippines’ climate conditions, focusing on heat dissipation, humidity control, energy efficiency, and bird welfare.

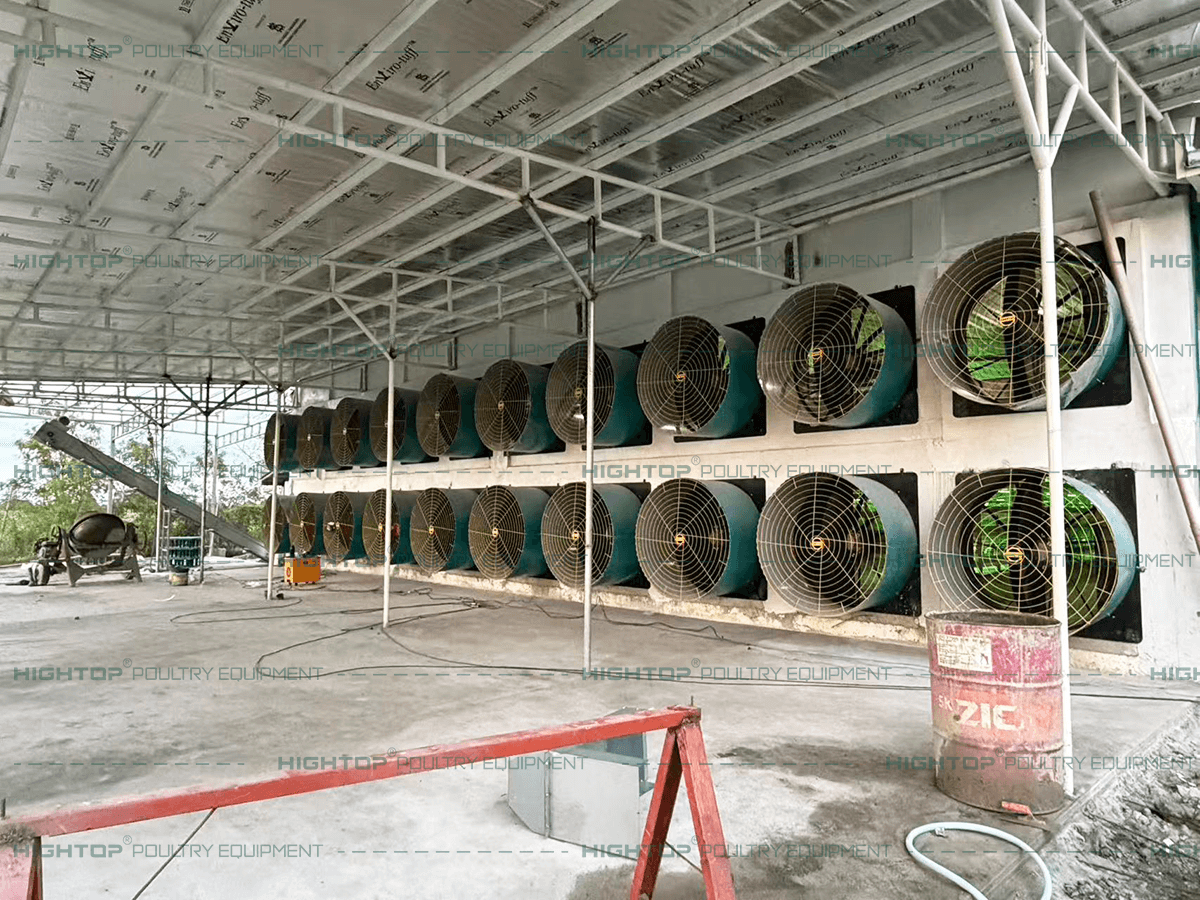

4. Core Upgrade Highlight: EC Fan Ventilation System

One of the most critical improvements in this project is the introduction of EC fans, which replaced conventional AC fans commonly used in older poultry houses.

4.1 Why EC Fans Were Chosen

In tropical broiler production, ventilation systems often operate 24 hours a day, making energy efficiency and airflow precision extremely important.

Traditional AC fans typically operate at fixed speeds or limited step control, leading to:

- Excessive power consumption

- Poor temperature control

- High noise levels

- Inflexibility under changing weather conditions

EC fans, supplied by HIGHTOP Poultry Equipment, were selected to overcome these issues.

4.2 Technical Advantages of EC Fans in Poultry Houses

Variable Speed Control (0–100%)

EC fans support stepless speed adjustment, allowing airflow to match real-time temperature, humidity, and stocking conditions. This ensures:

- Stable internal climate

- Reduced heat stress

- Improved bird comfort

Significant Energy Savings

Compared with traditional AC fans, EC fans can reduce electricity consumption by at least 40%, and in some operating modes even more.

For this 90,000-bird enclosed broiler house, this translates into:

- Substantial monthly electricity cost savings

- Faster return on investment

- Lower long-term operational expenses

Lower Heat Generation and Noise

EC motors produce less internal heat and operate more quietly, which:

- Reduces secondary heat load inside the house

- Minimizes stress on broilers

- Improves overall flock behavior

High Reliability and Long Service Life

With brushless motor design and stable electronic control, EC fans:

- Have fewer mechanical wear parts

- Offer longer service life

- Require less maintenance

4.3 Impact on Ammonia and Fly Control

Thanks to precise airflow management and continuous ventilation:

- Ammonia concentration was significantly reduced

- Moisture accumulation under the cages was minimized

- Fly breeding conditions were effectively eliminated

Compared to the previous floor system, the new cage house achieved a cleaner, drier, and healthier environment, which directly improved broiler performance and working conditions for farm staff.

5. Benefits of Pull-Out Slat-Type Broiler Cage System

The pull-out slat-type broiler cage system is the core production equipment in this project and played a key role in achieving the farm’s upgrade objectives.

5.1 Double Chicken Capacity in the Same Footprint

By utilizing vertical space through multi-tier cages, the farm:

- Increased capacity from 40,000 to 90,000 birds

- Improved land-use efficiency

- Reduced cost per kilogram of broiler meat

This is especially valuable in regions where land acquisition is costly or limited.

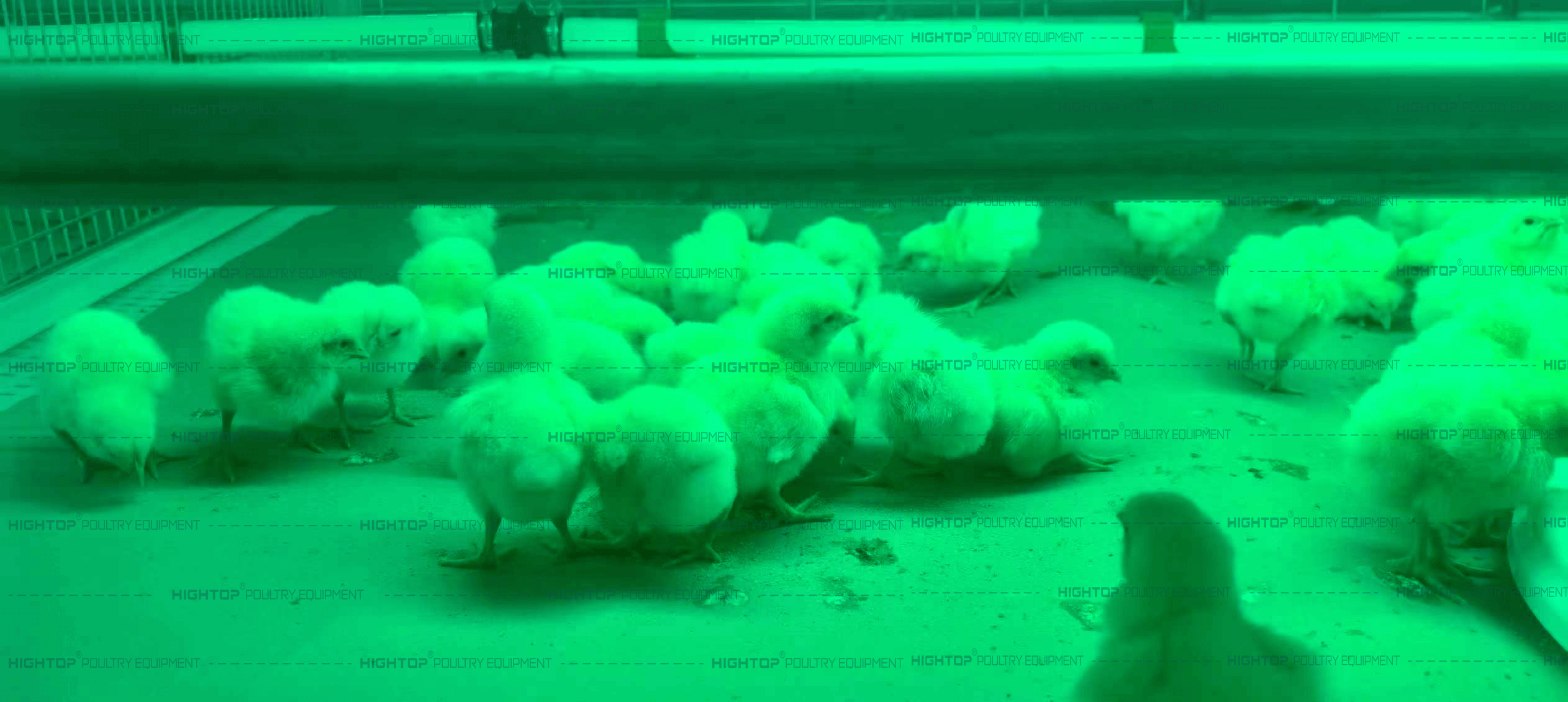

5.2 Clean Production and Reduced Disease Risk

With birds raised above the manure belt:

- Direct contact between chickens and manure is eliminated

- Ammonia emissions are reduced

- Disease transmission risks are lowered

This results in:

- Better flock health

- Lower mortality rates

- Reduced medication and veterinary costs

5.3 Efficient and Low-Stress Broiler Harvesting

The pull-out slat system allows:

- Birds to be gently transferred onto the manure belt during harvesting

- Automatic transport of birds out of the chicken house

This method:

- Greatly reduces labor intensity

- Minimizes bird injury and stress

- Improves harvesting efficiency and consistency

5.4 Easier Daily Management

Compared to floor rearing, the cage system offers:

- Cleaner working environment

- Simplified manure handling

- Reduced manual labor

- More predictable production outcomes

Farm management becomes more standardized and scalable.

6. Project Results and Client Feedback

After commissioning and several production cycles, the client reported clear improvements:

- Production capacity more than doubled

- Electricity consumption reduced by at least 40% due to EC fans

- No significant ammonia or fly problems

- Easier daily management and lower labor demand

- Stable growth performance at 1.8 kg market weight

- Improved biosecurity and house hygiene

The client confirmed that the conversion from a floor system to a pull-out slat cage system with EC fan ventilation was a decisive step toward long-term, sustainable broiler production.

7. Conclusion and Recommendation

This project demonstrates that, even in hot and humid regions like the Philippines, modern enclosed broiler houses with EC fan ventilation and pull-out slat cage systems can achieve:

- Higher production density

- Lower energy consumption

- Improved environmental control

- Better broiler welfare and performance

- Strong economic returns

Based on the successful conversion of this 90,000-bird broiler farm, HIGHTOP Poultry Equipment’s pull-out slat-type broiler cage system, combined with high-efficiency EC fans, is strongly recommended for poultry producers seeking to upgrade from traditional floor systems to modern, high-capacity, energy-efficient operations.

For farms aiming to double capacity, reduce operating costs, and improve management efficiency, this solution represents a future-ready investment in commercial broiler production.