Case Study: Large-Scale Layer Farm in the Philippines Uses HIGHTOP’s A-Type Cage System for 17,280 Laying Hens

Summary

This project in the Philippines is a prime example of how HIGHTOP Poultry Cage helps customers succeed with smart poultry farming investments. The farm now enjoys:

- Higher daily egg output

- Lower egg breakage

- Minimal manual labor

- Long-term system durability

- Efficient use of land and building resources

At HIGHTOP, we deliver not only equipment but also complete support—from design and manufacturing to installation and training. Our mission is to help poultry farmers worldwide achieve long-term success through smart, scalable, and sustainable systems.

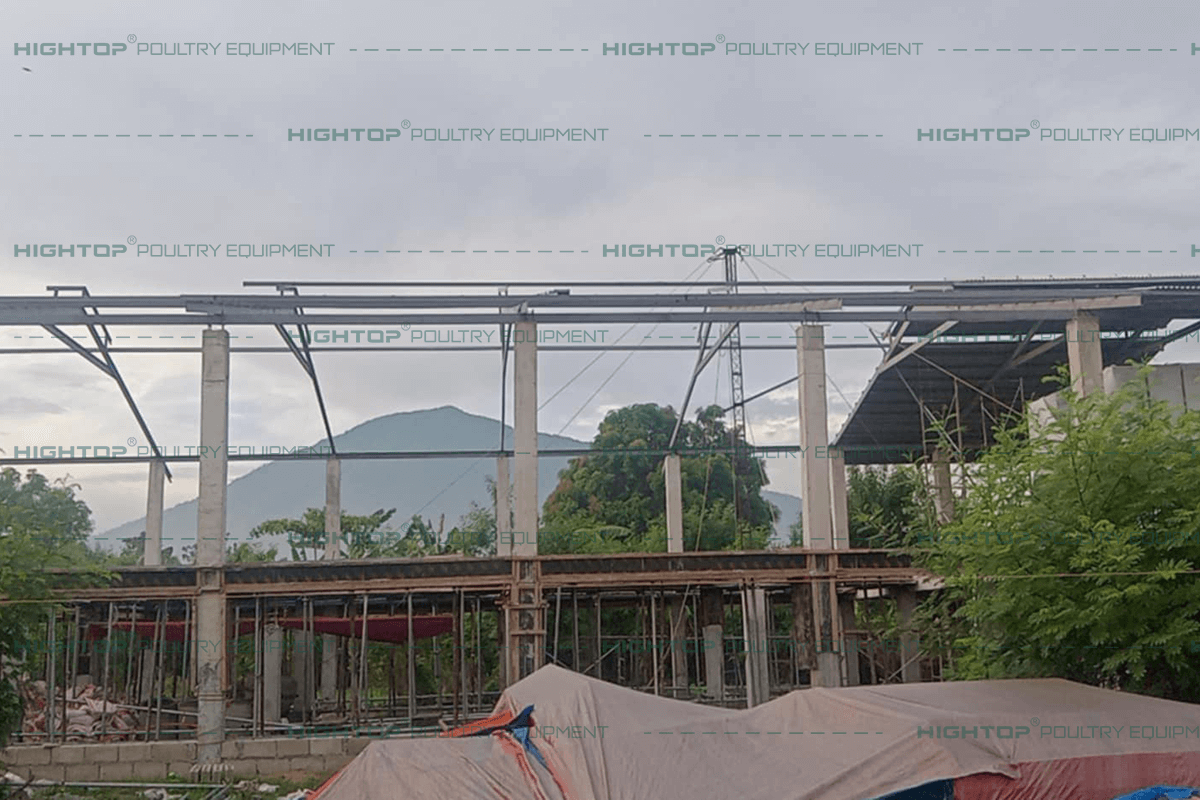

📌 Project Overview

Project Location: Philippines

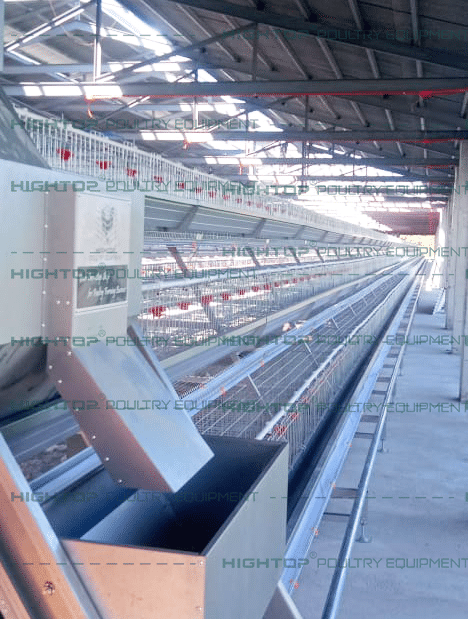

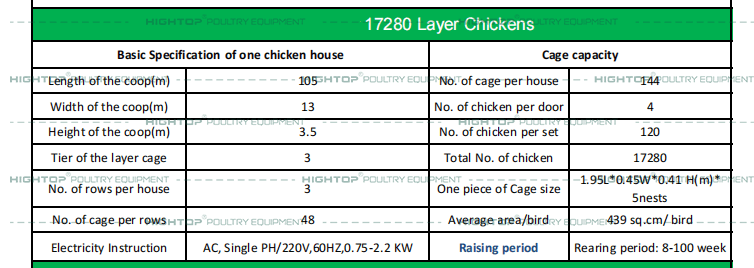

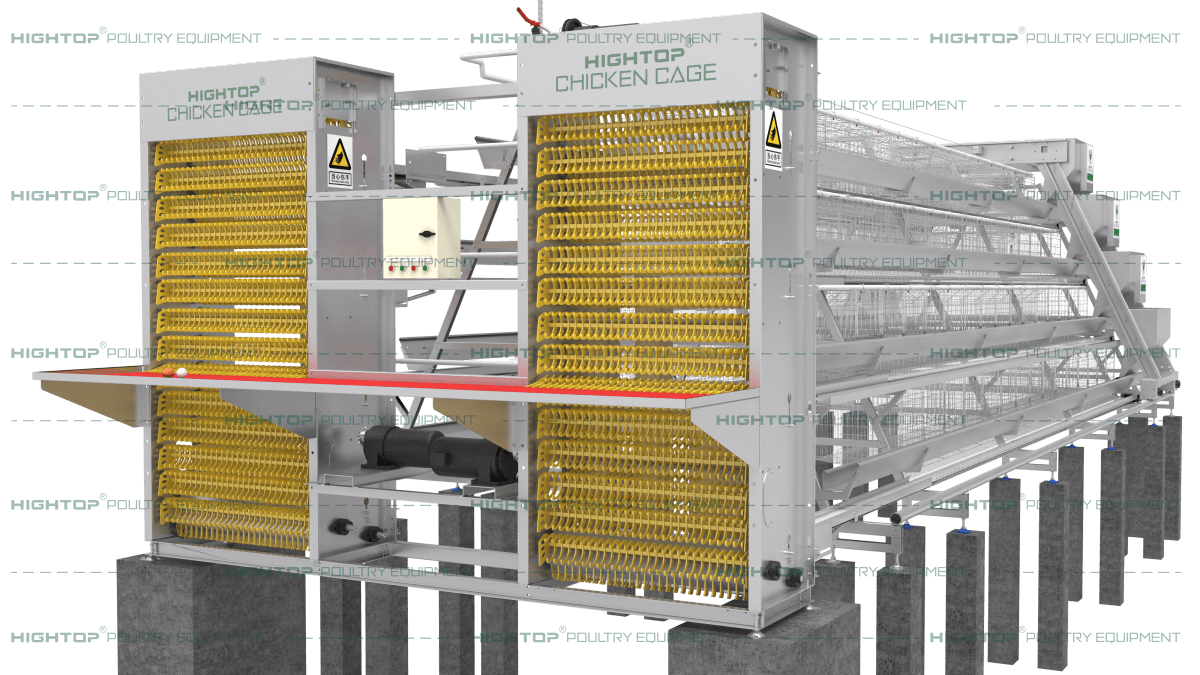

Cage Type: 3-layer A-type automatic layer cage with metal trough

Feeding System: Open hopper feeding

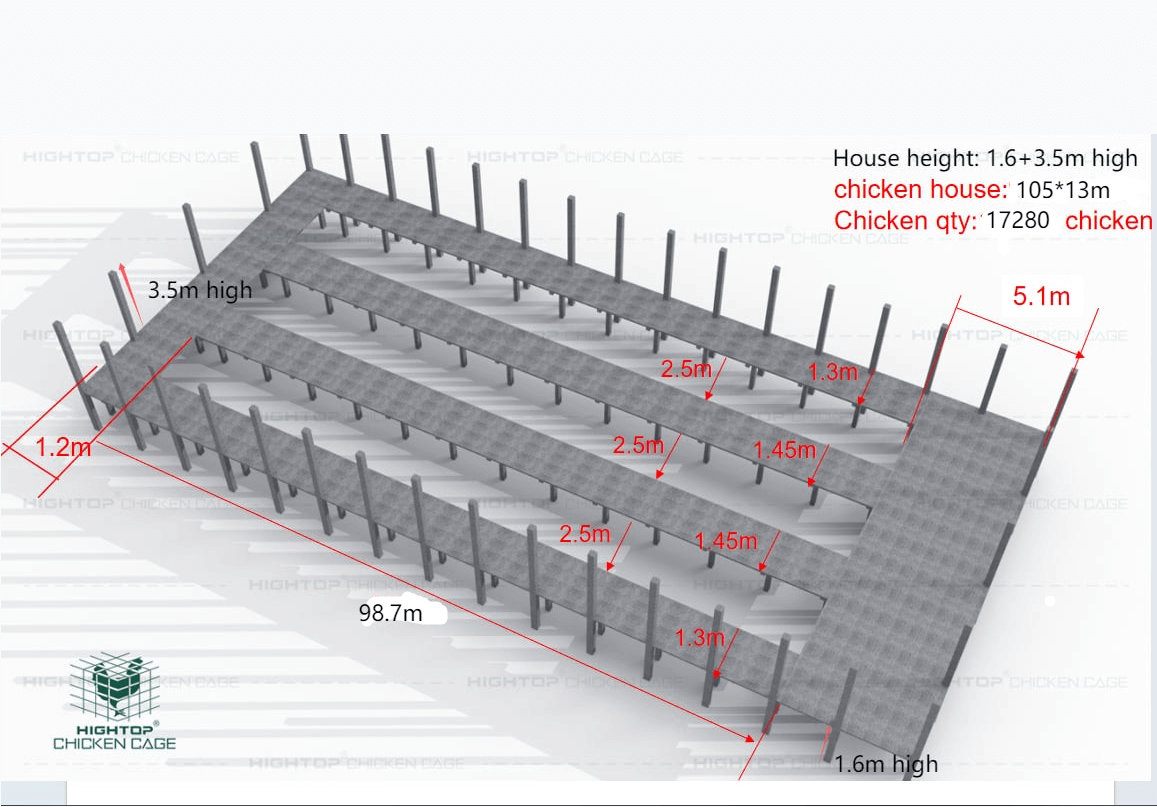

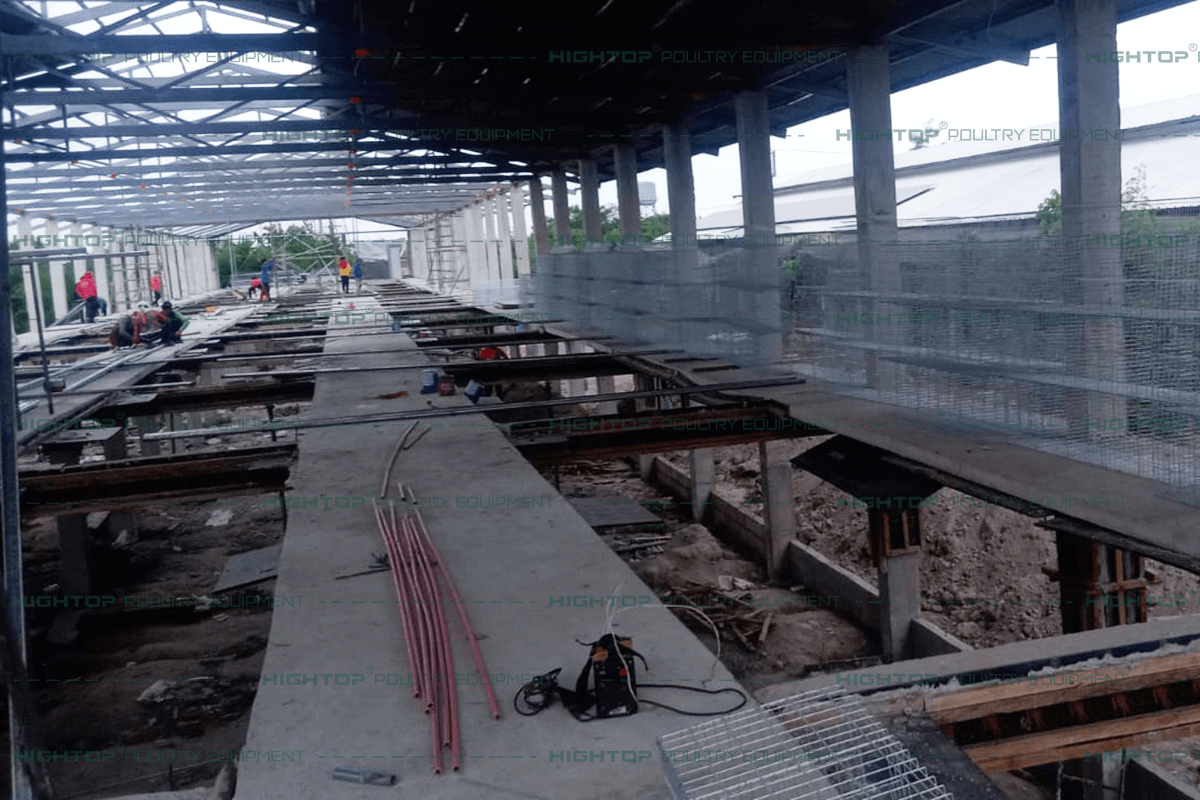

House Size: 105m × 13m × 3.5m (elevated open chicken house)

Layout: 3 rows per house, 48 cage sets per row

Capacity per House: 17,280 laying hens

Included Systems:

- Automatic drinking water system

- Automatic feeding system

- Automatic egg collection system

- Fans and ventilation equipment

- Installation tools and accessories

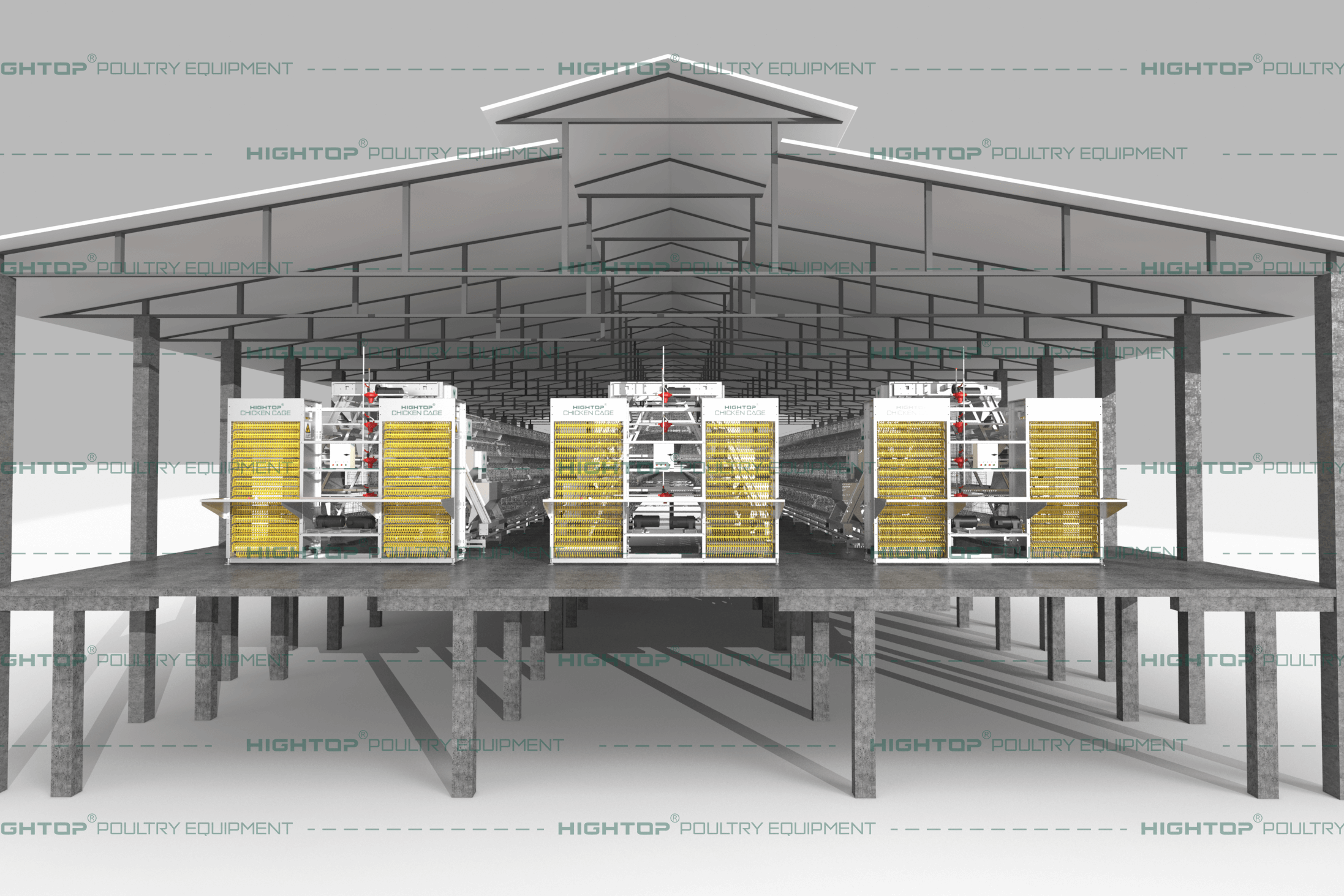

Project Display

Here are visual highlights from the project installation.

This farm relies on HIGHTOP’s 3-layer A-type cage system with metal troughs, one of the most efficient and durable solutions for commercial layer operations.

✔ Key Product Benefits:

-

Boosts Egg Production to Over 96%

The A-type design ensures bird comfort, efficient feeding, and proper lighting, which significantly boosts laying performance. -

Minimizes Egg Breakage (<0.5%)

The cage slope and metal trough guide eggs smoothly to the collection point, reducing damage and losses. -

Long-Term Durability (20-Year Lifespan)

Constructed with Q235 hot-dip galvanized steel, this cage system withstands corrosion and wear even in humid or tropical environments—perfect for farms in Southeast Asia. -

Full Automation Saves Labor

The included systems for feeding, drinking, and egg collection reduce labor costs dramatically—just a few workers can manage thousands of birds.

This cage system is ideal for poultry farmers who need high-volume, low-maintenance, long-term layer farming solutions.