Case Study: Expansion of a 88,800-Bird Broiler House with Green-Light Environmental Control

Following the successful completion of the client’s first broiler house project, which can be viewed here: 88,800 Birds/Building Broiler Cage Chicken House, the customer expressed strong satisfaction with the performance of Hightop’s automated broiler cage system. The equipment had significantly improved production efficiency, reduced labor demand, and ensured stable flock performance throughout the cycle. Based on this positive experience, the client contacted us again to plan the expansion of a second chicken house of the same capacity.

Customer Feedback and New Requirement: Adding Green Light for Chick Brooding

After operating the first house for several production cycles, the customer offered constructive feedback. They reported that the birds had excellent consistency, fast growth, and low mortality, but they hoped to further optimize chick brooding conditions during the first week.

Specifically, the customer requested the integration of green lighting into the environmental control system for the new expansion project.

Because green light has scientifically proven benefits for day-old broilers, Hightop agreed to incorporate this requirement into the design without additional complexity.

Why Green Light Is Used for Raising Day-Old Broiler Chicks

1. Enhances Visual Development and Behavioral Stability

Chicks’ visual systems develop rapidly after hatching, and they respond particularly well to wavelengths between 490–570 nm, which correspond to green light.

Green light provides:

-

A softer, more comfortable visual environment

-

Faster adaptation to new surroundings

-

Reduced startle responses and disorderly running

-

Stronger early feeding and drinking behavior

This early establishment of eating and drinking patterns is critical for survival and growth.

2. Reduces Feather Pecking and Aggression

Feather pecking and vent pecking are common in chicks, especially under bright or unsuitable light sources.

Green light:

-

Lowers flock excitability

-

Reduces aggressive pecking

-

Decreases skin injuries and chick mortality

Compared with white or red light, broilers under green light remain noticeably calmer.

3. Promotes Early Growth and Feed Efficiency

Research shows that green light influences melatonin secretion and circadian rhythm regulation. This supports:

-

Higher feed intake

-

Faster weight gain

-

Better feed conversion ratios (FCR)

These advantages accumulate over time and result in stronger early uniformity.

4. Mitigates Stress During Brooding

The brooding phase is highly stressful due to temperature change, transportation, and a new environment.

Green light provides a calming effect and helps:

-

Lower stress hormone levels

-

Improve adaptation during the first 3–5 days

-

Reduce early chick mortality

5. Works Seamlessly with Light Management Programs

In early brooding, farms often use 23 hours of light to encourage feeding. Green light provides adequate brightness while avoiding overstimulation.

As chicks grow, lighting can then shift to white to support later-stage growth.

Comparison with Other Light Colors

-

Red light: Good for reproductive maturity but may increase pecking (not ideal for broilers).

-

Blue light: Very calming but may suppress feed intake in the first week.

-

White light: Full spectrum, but easy to overstimulate chicks if the intensity is not well controlled.

Given this scientific evidence, Hightop incorporated green LED lighting into the customer’s new broiler house design.

Design Phase

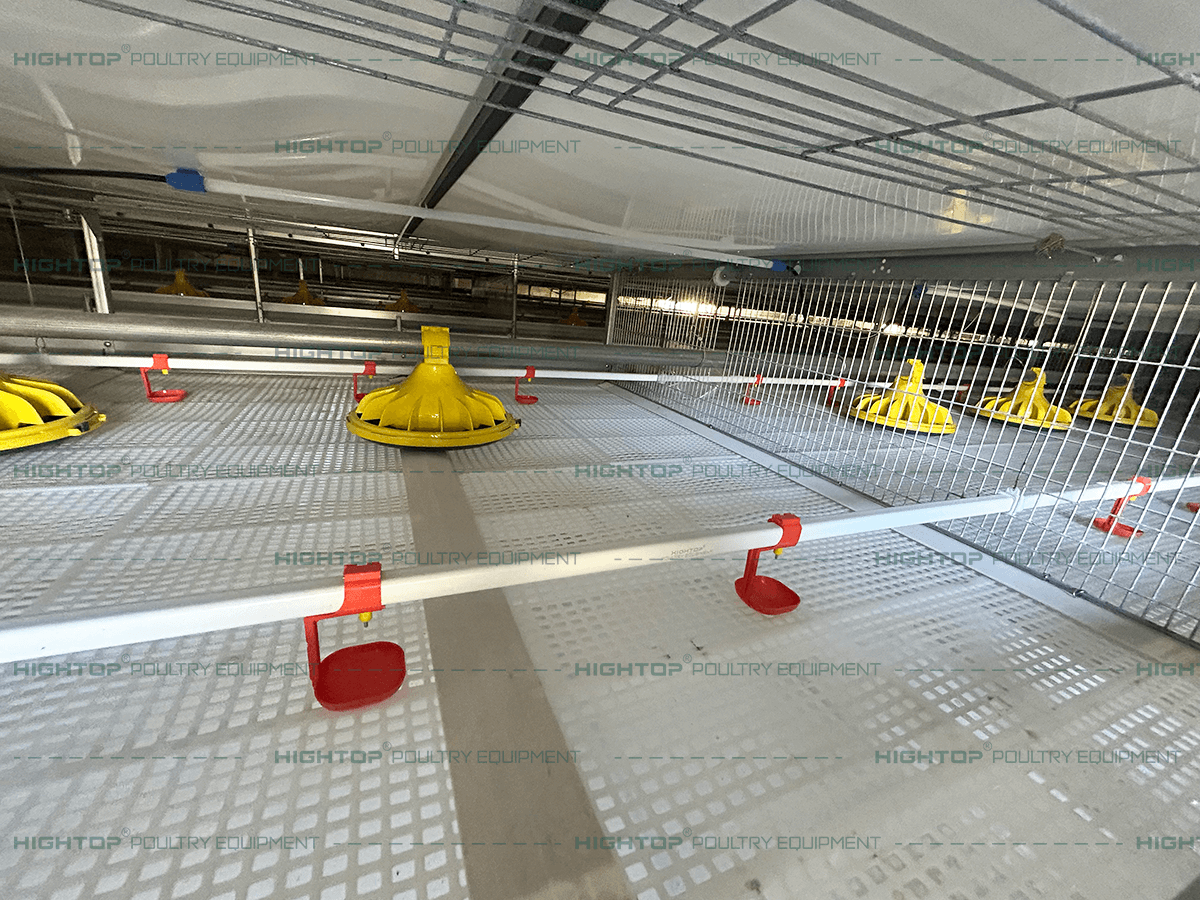

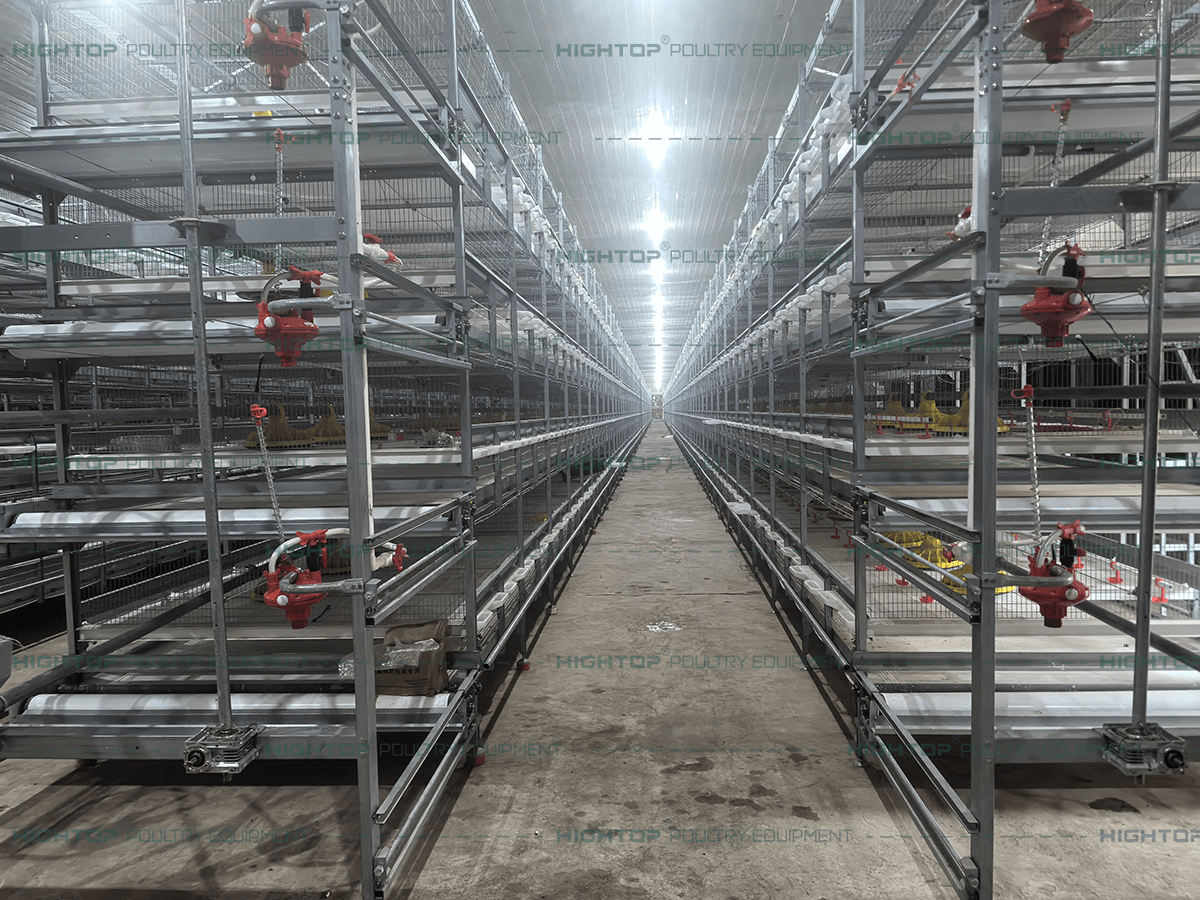

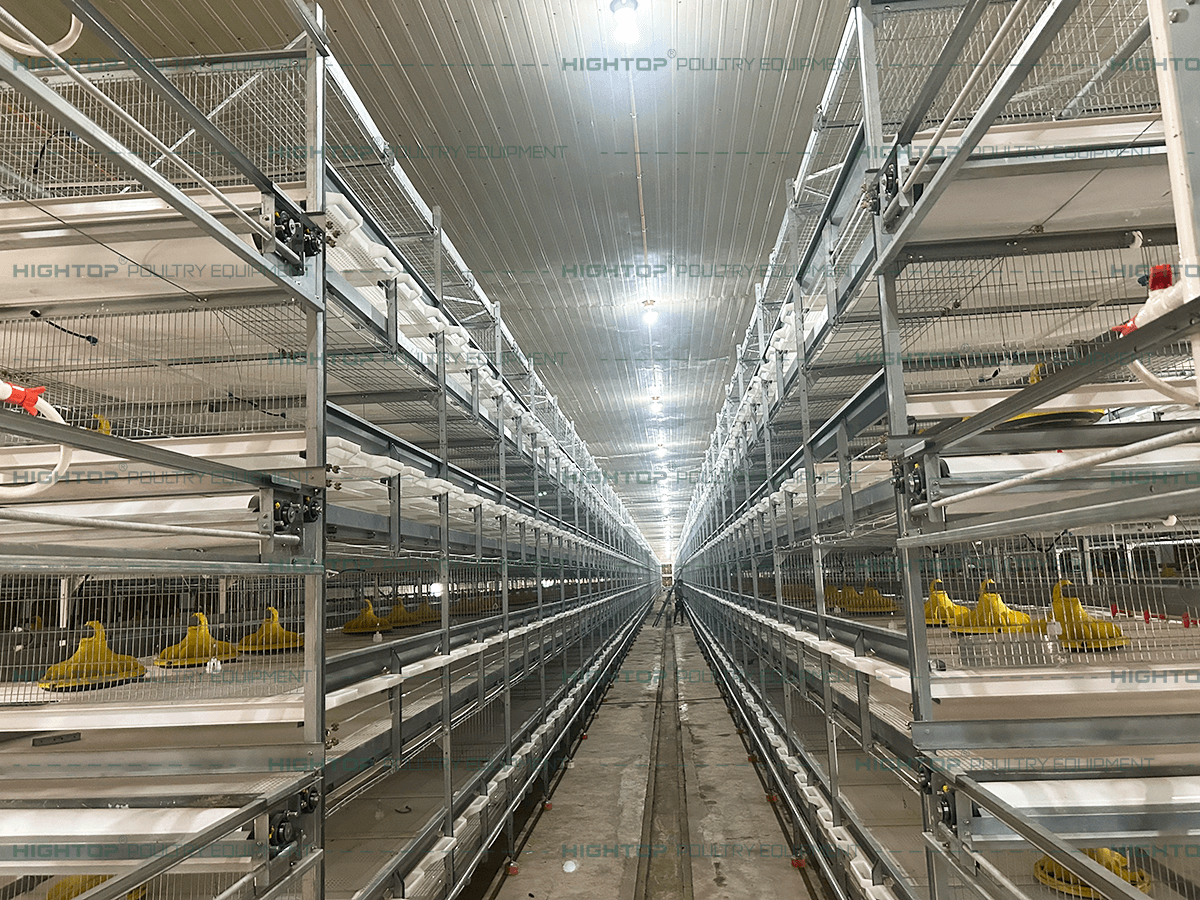

Based on the existing farm layout and the customer’s expansion plan, Hightop designed the new broiler house around the same pull-out cage system used in the first building. The system layout included:

- Pull-out broiler cage system

- Automated feeding and watering system

- Manure conveyor cleaning system

- Lighting system with integrated green light module

- Environmental control system including fans and water curtains

The design goal is to improve brooding performance by optimizing lighting while ensuring consistency with the customer’s existing chicken house style.

Project Image Details

Packaging and Shipment

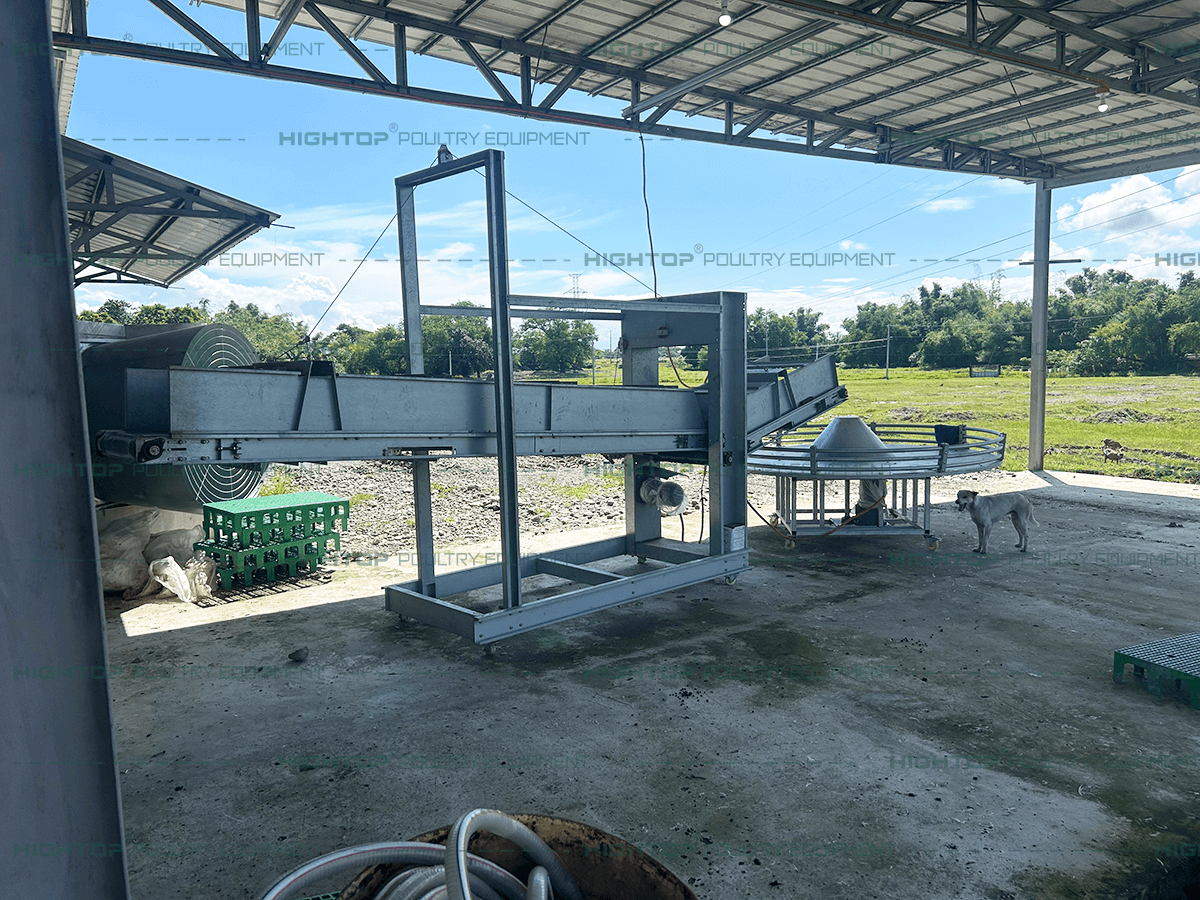

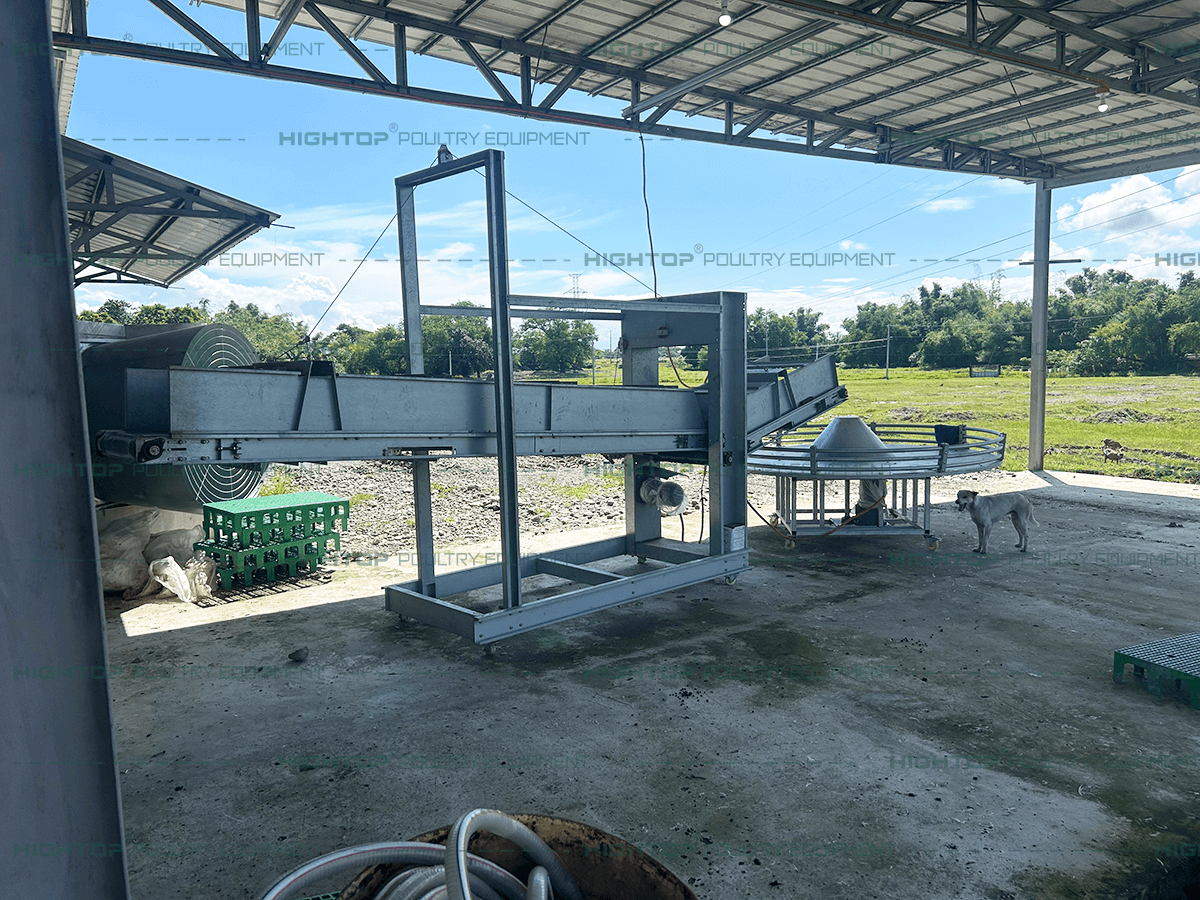

Chicken house external harvesting system

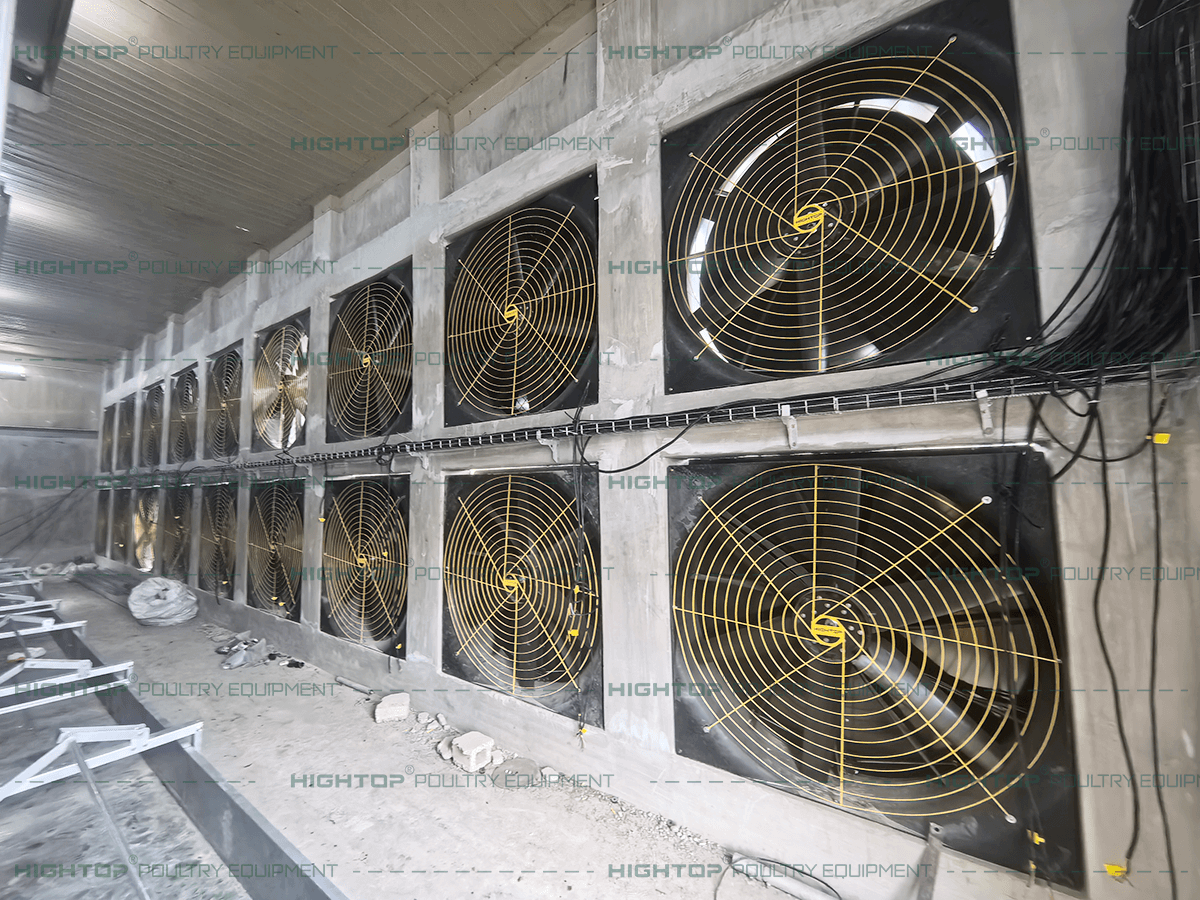

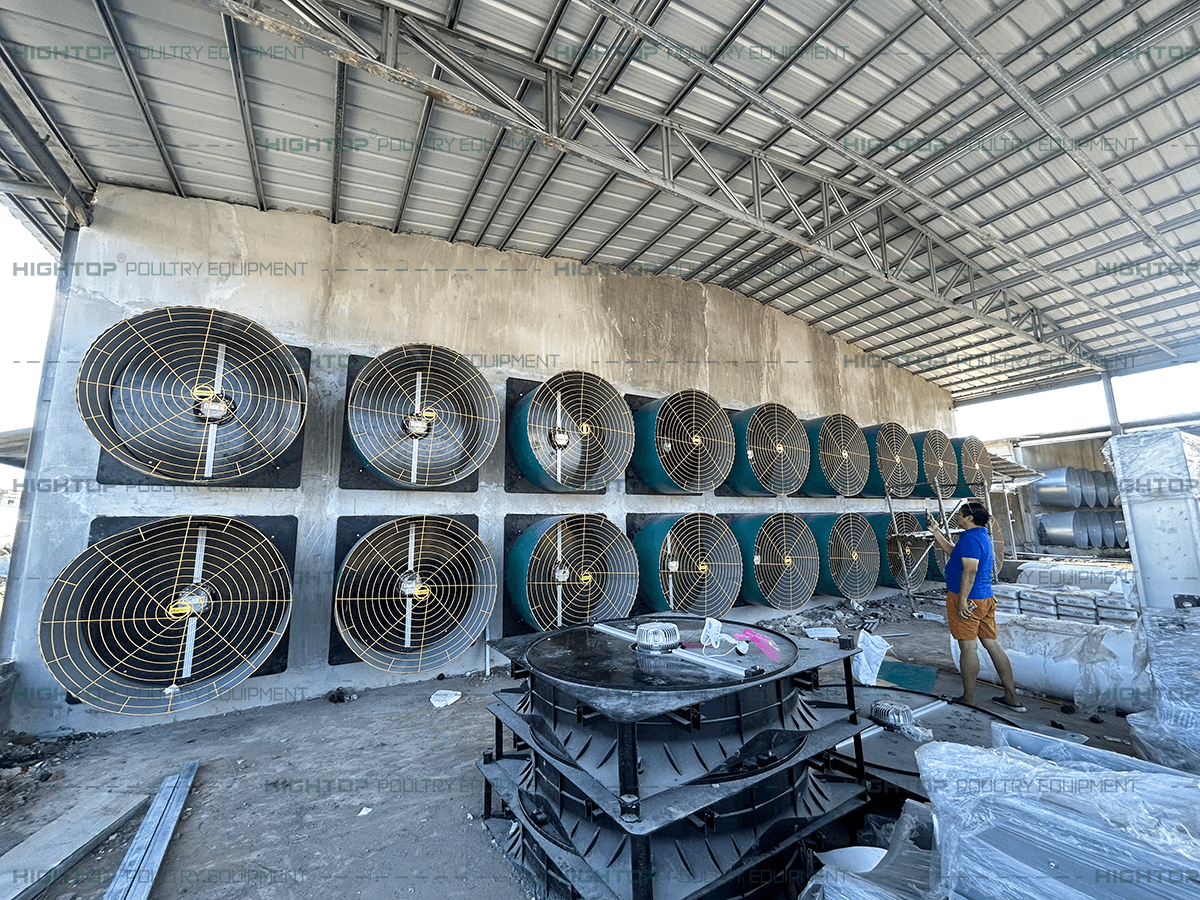

Chicken House EC Fan

Comparison Table: EC Fans vs. Conventional AC Fans in Poultry House Ventilation

| Application (Poultry House) | EC Fan | Traditional Galvanized AC Fan |

|---|---|---|

| Energy Consumption | 10%–40% lower energy consumption | Low working efficiency, significant energy waste |

| Operating Cost & Investment | Significantly reduces electricity consumption during long-term operation, faster return on investment, higher farming profitability | Low initial investment, but high long-term electricity consumption affects overall farming returns |

| Ventilation Precision | Stepless speed regulation from 30%–100%, reduces cold stress in poultry; built-in variable frequency control | Safe speed regulation range is 70%–100%; limited low-speed control may affect young birds; inverter required separately |

| Temperature & Humidity Control | Environmental controller enables multiple fans to run at reduced speed, improving airflow uniformity | Control achieved by switching fan numbers on/off, resulting in less uniform ventilation |

| Noise Level | PP material with one-piece injection molding and optimized aerodynamic design; higher blade efficiency, significantly lower noise and vibration | Mostly stainless-steel blades; limited processing precision affects dynamic balance; higher noise and vibration |

| Automation Compatibility | Supports RS485-Modbus communication or 0–10V analog control; easy digital integration and management | Controlled by power switch only; no signal communication capability |

| Motor Stability | Wide operating voltage range; automatic speed adjustment adapts to voltage fluctuations; continues running even with phase loss | Voltage fluctuations easily cause motor overheating and premature bearing failure; cannot operate under phase loss |

| Reliability in Humid Environments | Motor protection rating IP66; can be directly washed with a water hose | Typically IP54 or IP55; weaker protection against moisture |

| Service Life | Direct-drive, maintenance-free design; service life of 10 years or more; suitable for large-scale farming | Belt-driven; belts require regular replacement to maintain airflow; typical service life 3–5 years; suitable for small-scale farms |

| Installation & Space Cost | Integrated fan body with high structural stability; delivers higher airflow with the same wall opening size | Assembled structure; lower airflow output with the same wall opening size |

| Negative Pressure Resistance | Suitable for high-density farming; negative pressure resistance up to 125 Pa | Suitable for low-density farming; typically used below 50 Pa |

For modern broiler and layer farms, EC fans provide:

-

Lower electricity costs

-

More stable temperature and air quality

-

Better bird welfare and performance

-

Higher automation compatibility

-

Longer equipment lifespan

While conventional AC fans may have a lower initial purchase price, EC fans deliver superior long-term economic and production benefits, especially in large-scale, enclosed poultry houses.

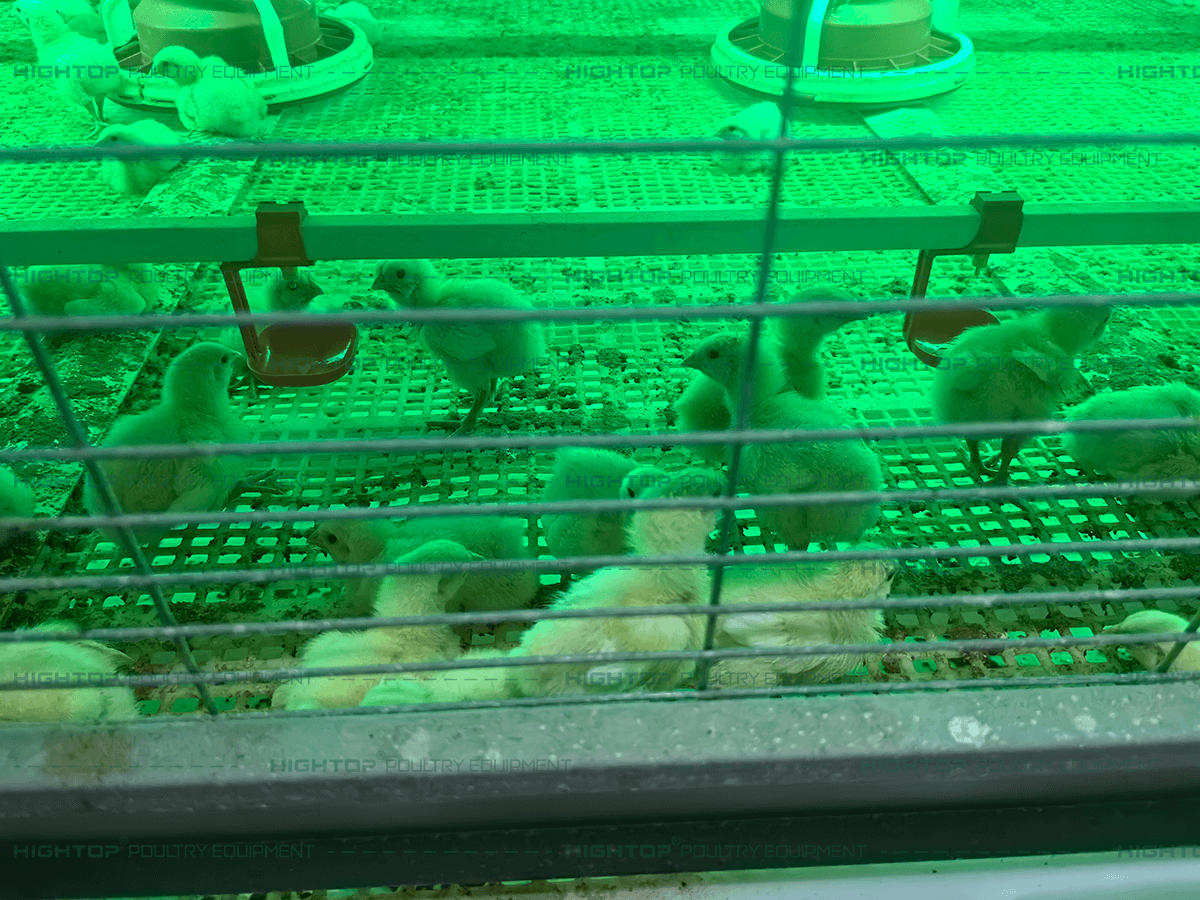

Chick Placement and Results

Once installation and debugging were completed, the customer placed day-old chicks into the new house. Because the new building featured both the automated broiler cage system and the green-light environmental control, the flock showed outstanding early results:

-

Chicks immediately located feed and water

-

Noticeably calmer behavior

-

Significant reduction in early pecking incidents

-

Better chick uniformity in the first 10 days

-

Lower early mortality compared with the previous house

-

Stronger early growth curves

The customer confirmed that the green-light system improved brooding conditions beyond what was achieved in the first house.

With the successful completion of this expansion project, the customer now operates two high-capacity broiler houses equipped with Hightop’s automated cage systems. The addition of green-light technology has further optimized chick brooding and early development, producing measurable improvements in flock behavior, uniformity, and survival rates. The customer has expressed strong satisfaction with both the performance of the new system and the stability of Hightop’s engineering support.

If you are interested in this project, please contact us and we will customize the most suitable solution for you based on your specific circumstances!