4 Chicken Houses Using HIGHTOP A Type Layer Cages for 32,000 Birds

📝 Summary

This case study highlights the success of a poultry farm in expanding from two to four high-rise chicken houses using HIGHTOP’s 3-layer A-type layer cage system. The farm not only achieved outstanding egg production and quality results but also benefited from a cage system that balances performance, durability, and affordability.

Whether you’re starting a new poultry business or upgrading an existing one, HIGHTOP’s A-type cage system offers a reliable and proven solution tailored to your needs.

📍 Project Overview

In October 2023, a poultry farm client partnered with HIGHTOP Poultry Cage to begin the construction of two high-efficiency chicken houses. These houses were completed and put into use in May 2024, and based on the excellent results, the client placed a second order in October 2024 for two additional houses.

Today, the farm operates four chicken houses, each capable of housing 8,000 laying hens, for a total of 32,000 birds. Each house is equipped with one row of cages using 3-layer A-type cages.

🏗️ Chicken House Layout

Number of Houses: 4

Capacity per House: 8,000 laying hens

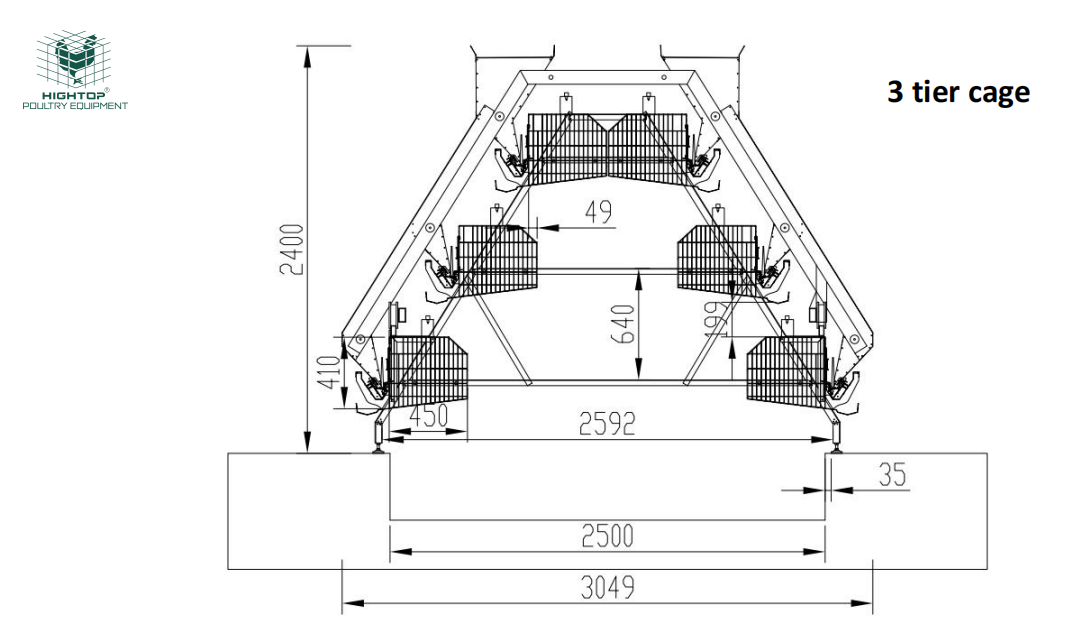

Cage Configuration: 3-tier A-type cages

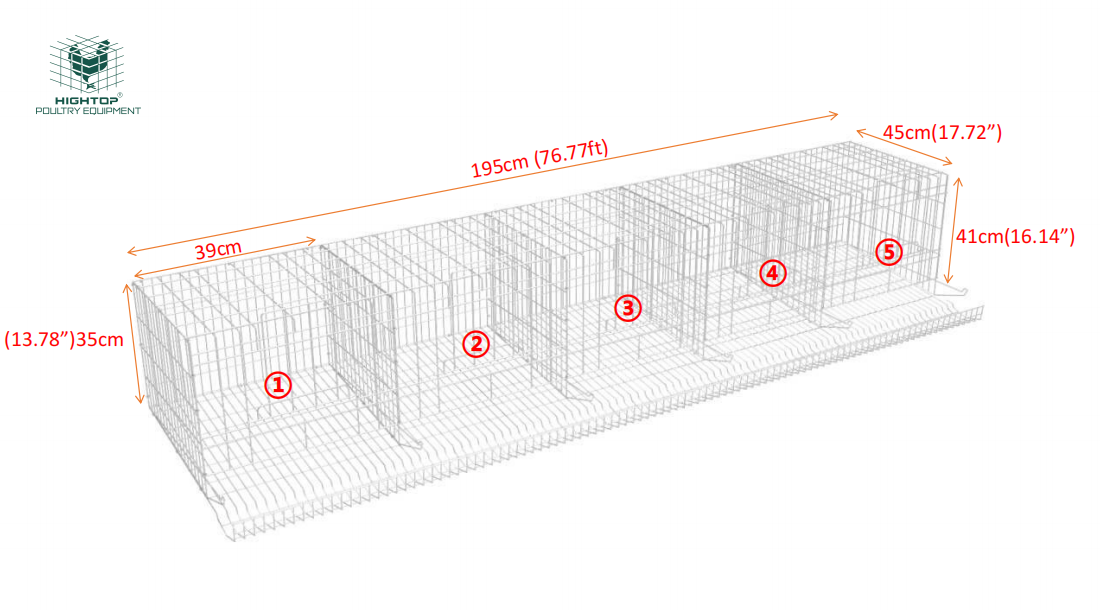

Cage Size: 195cm (L) × 45cm (W) × 41cm (H)

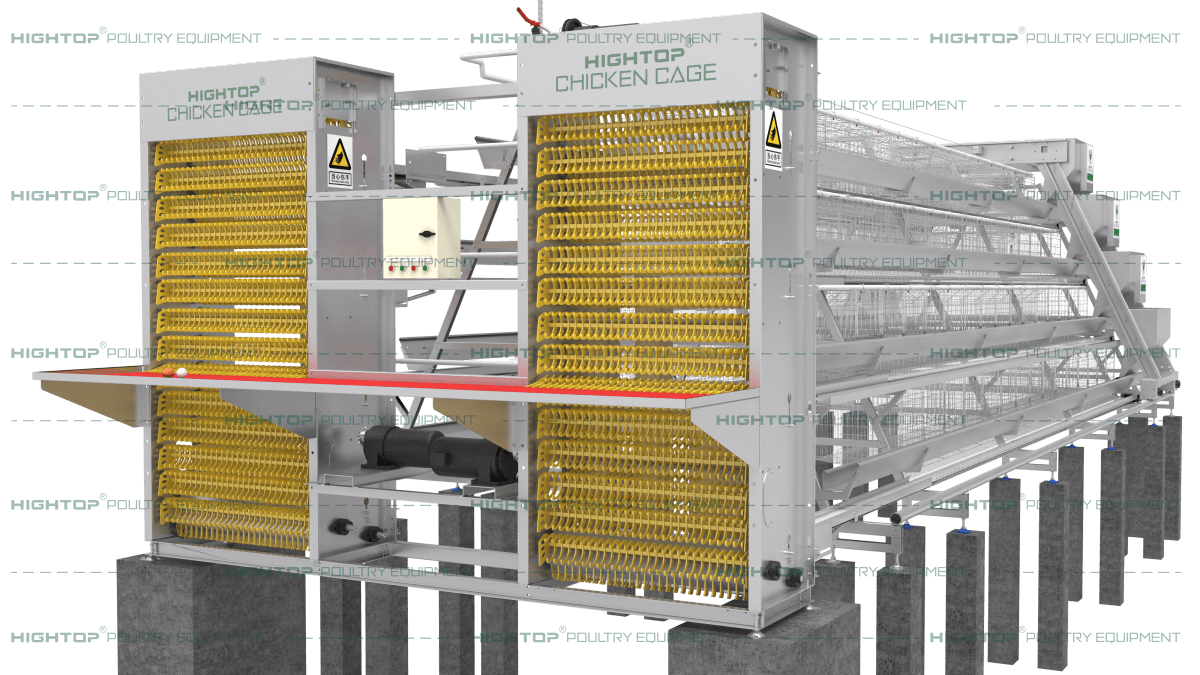

Feeding System: Closed bucket feeding

Manure Cleaning System: Scraper-type

Chicken House Design: High-rise design

House Dimensions:

- Width: 4.9m (including 1.2m aisle)

- Span: 2.5m

- Length: 141m

📸 Project Display

Our team provided comprehensive support throughout the project:

✔️ Customized layout design

✔️ Cage and equipment manufacturing

✔️ Shipping and delivery

✔️ Installation guidance and after-sales follow-up

🛠️ Product Recommendation: A-Type Layer Cage System

This farm uses our best-selling A-type 3-tier layer cage system, known for its outstanding value and performance. It’s the perfect solution for small to mid-sized commercial farms, particularly for those housing 5,000 to 20,000 birds per house.

Click to view more A type laying hen cage product details

✅ Key Product Advantages

-

High Egg Production Rate

Proven results from this customer show an egg production rate exceeding 96%, ensuring maximum return on investment. -

Low Egg Breakage Rate

With an egg breakage rate of less than 0.5%, egg quality and quantity remain consistently high, improving market competitiveness. -

Extended Cage Lifespan

The cage is made of Q235 hot-dip galvanized steel, giving it a service life of up to 20 years, significantly reducing maintenance and replacement costs. -

Flexible Automation Options

This cage system supports closed, semi-open, or open chicken houses, and customers can choose from various automatic systems—feeding, manure cleaning, egg collection—based on their budget. -

Cost-effective Alternative

While delivering all the necessary features of a modern cage system, this A-type model comes at a lower initial investment compared to fully integrated automated cages.