Project Overview

This case study shows a mature Philippine layer farm modernizing with HIGHTOP’s H-Type battery cage system. The project’s 85 m × 10 m houses now hold 20,412 hens in three-level cages, all fed, watered, and managed automatically. Compared to its old methods, the farm dramatically saved space and labor – collecting eggs in 2 hours instead of 6–8 – while providing better hen comfort and health. Automation cut the broken-egg rate to near zero and allowed staff to focus on management rather than chores. Overall, the HIGHTOP H-Type solution achieved higher productivity and profits by “saving land and investment” and optimizing every aspect of egg production.

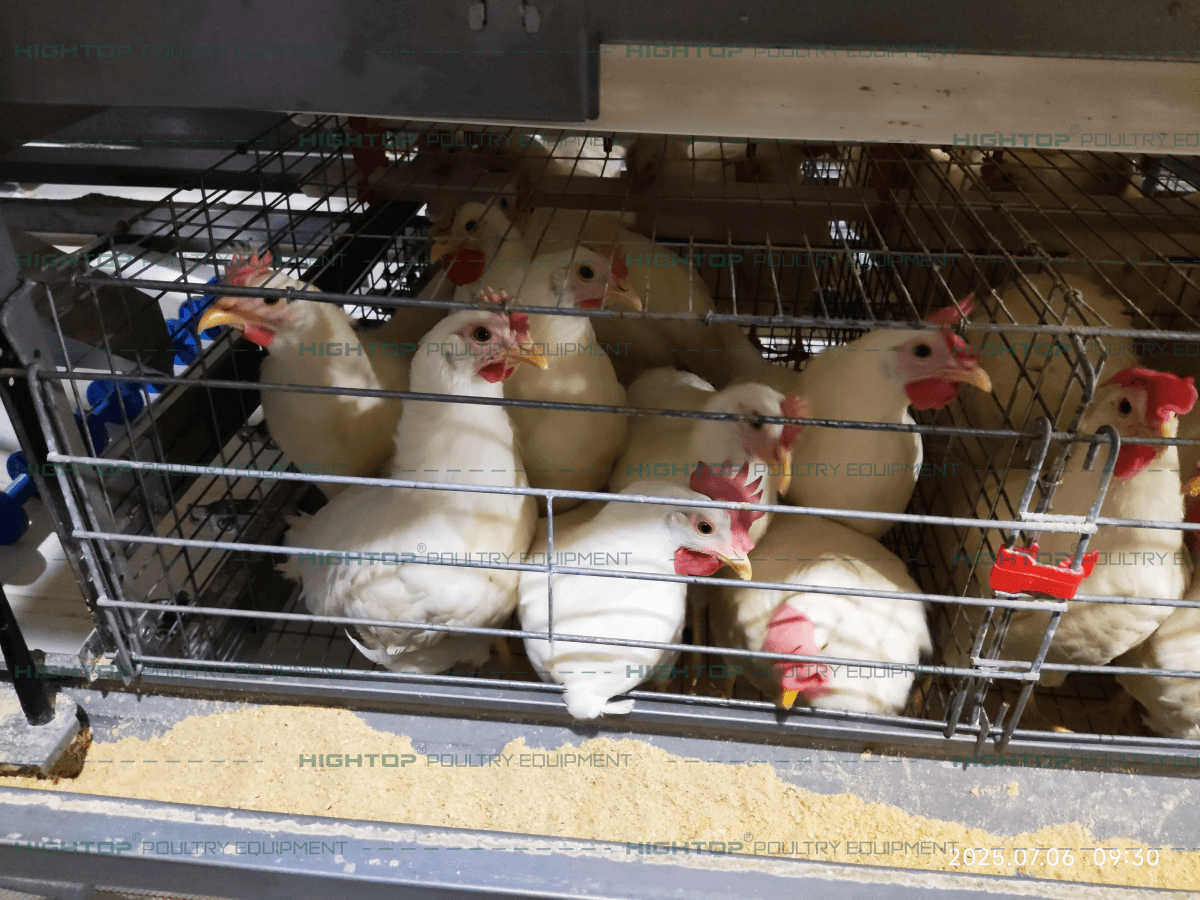

A commercial layer farm in General City, Philippines, installed a HIGHTOP H-Type battery cage system to house 20,412 hens. Each chicken house measures 85 m (L) × 10 m (W) × 3.5 m (H) and contains 3 rows of cages. There are 63 cage sets per row (189 sets per house), each cage set holding 108 birds. The cages are a 3-tier H-type design (cage dimensions 1.2 m × 0.625 m × 0.70 m per set, with two nests of 60 × 62.5 cm each), giving an average space of 417 cm² per bird.

The farm chose HIGHTOP’s H-type automatic layer cages for their known advantages: high-density layout to save land and cut construction costs, multi-tier flexibility (3–5 tiers possible), and full automation of feeding, drinking, egg collection and manure removal. This automation reduces labor, minimizes egg handling, and improves environmental control – all boosting egg production and profitability

Project Display

HIGHTOP’s H-type system equips each cage tier with automatic feeders, waterers and a conveyor egg-collection belt. This integrated design delivers feed and water to hens with minimal waste, collects eggs efficiently, and routes manure out of the cages.

Inside the house, the sturdy H-frame supports three levels of cages. Each level has sloped floors so eggs roll onto conveyors, and an automatic manure removal belt under each tier that continuously strips away droppings. The sloped mesh and belts keep birds clean and eggs intact (broken-egg rate <0.05%). This high level of automation means workers spend far less time on egg collection and cleaning; egg pickup that once took 6–8 hours now takes about 2 hours, with far fewer broken eggs and disease risks.

Product Recommendation

Based on this project’s experience and the known advantages of HIGHTOP’s H-Type cages, the HIGHTOP H-Type Automatic Battery Cage System is strongly recommended for commercial layer operations. Its high-density, H-frame design allows 3-tier (up to 5-tier) stacking, so a farm can raise up to 20 hens/m² compared to just 5–6 hens/m² on the ground. This means more birds in the same footprint, saving land and construction costs.

Key benefits include:

- Labor & Time Savings: Fully automated feeders, drinkers, egg belts, and manure belts handle daily chores. Fewer workers are needed even as flock size grows, and egg collection time is cut by ~75%, greatly reducing labor costs.

- Higher Production: Consistent feed/water delivery and stable house climate (temperature, humidity, lighting) improve hen comfort and laying rates.

- Improved Profitability: Automated egg collection minimizes human handling – egg breakage falls to <0.05% – and healthy conditions reduce disease, so the farm gains more saleable eggs per bird.

- Scalability: The H-type cages can be configured for 3 to 5 tiers per set, fitting 10,000–80,000+ hens per house as needed. This flexibility lets farms expand easily.

In this case, HIGHTOP’s equipment helped the Philippine farm meet all its goals: raising more hens per house, cutting labor and egg-breakage rates, speeding up operations, and increasing overall egg production. For any commercial layer farm, especially in Southeast Asia, HIGHTOP’s H-Type Battery Cage System offers a proven turnkey solution to grow capacity and efficiency