Why choose broiler cages?

1. They save space.

More broilers can be fed in the cage putting the space to better use. The A type of broiler cage has three tiers, with the third cage near to the ground. The second and top tiers are on top of the third tier. Facts prove that the capacity in broiler cage is three or four times than on ground in same area.

2. They save feed.

The old way to feed is on the ground, with broilers eating, walking and sleeping on the ground. Workers added food to the feeder, but they were not able to control the quantity of food. So they would simply feed the broilers a fixed amount at certain times.

3. They reduce the spread of disease

Ventilation is better in broiler cages than on the ground, which is how they help to prevent the transmission of disease and bacteria amongst the flock.

We have A and H type broiler cages as shown below

| Item No. | Type | Size (L x W x H) | Nos of Nest per Tier | Nos of Nest per Set | Nos of Broiler per Nest | Nos of Broiler per Set |

| HT-BH3 | “H” Type, 3 Tiers | 1.4 x 0.7 x 1.75m | 2 | 6 | 9 or 10 | 54 or 60 |

| HT-BA3 | “A” Type, 3 Tiers | 1.95 x 2.4 x 1.5m | 6 | 18 | 4 | 72 |

| Item No. Desc | “HT” – Hightop® brand; “B”-Broiler; “H” – H type/shape; “A”-A type; “3” – 3 tiers | |||||

| Material | Q195 low carbon steel wire or | |||||

| Q235 low carbon steel wire | ||||||

| The Finish | 1. Electro Galvanized or | |||||

| 2. Hot Dipped Galvanized or | ||||||

| 3. PVC Coated. | ||||||

| Life Span | Electro Galvanization (7-10 years); | |||||

| Hot Dip Galvanization (15-20 years); | ||||||

| PVC Coated (15-20 years) | ||||||

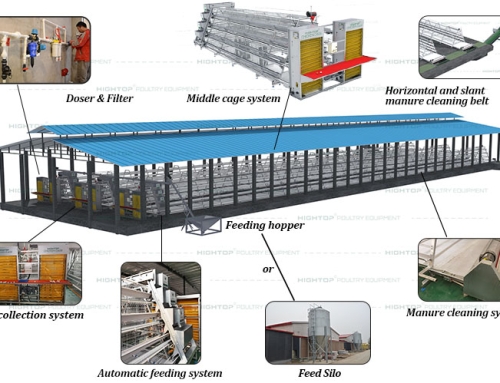

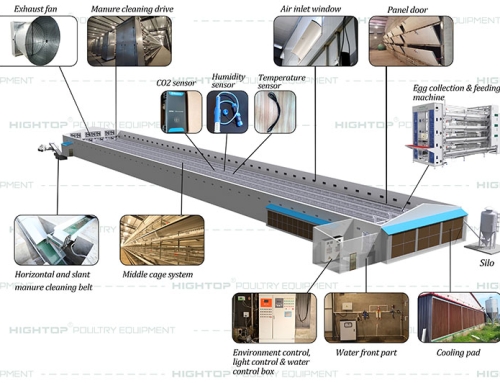

How to choose other equipment needed when using A type broiler cages

- If you hatch the chicks on your farm you may need an incubator and hatcher. We can provide equipment for a 48,000 to 50,000 egg capacity.

- A type broiler cages are suitable for between 4,000 and 10,000 birds or chicken. We suggest you also use a manure removal machine because by removing the droppings timeously you will help to reduce any spread of disease and improve egg production rate. At the same time it will save both time and labor costs. A semi-automatic feeding machine is also necessary. These are small and cost a lot less than fully automatic machines. They also use batteries so avoid the possibility of power failure. You can feed 10,000 chickens in just half an hour, which will save a lot in labor costs.

- If you have more than 10,000 chickens you may need to get fully automated machines including one that does automatic feeding, another for automatic egg collection, as well as an automatic manure removal machine. If the scale of your operation exceeds 50,000 chickens, you will need a feed silo. For less than 50,000 chickens you can just use one screw conveyer to convey the food to the hopper. If you want to build a closed system, you need to know that an exhaust fan and cooling pad are necessary environment control equipment items. If you use an open system and the weather is hot, you can use a fogger.

- If you want to purchase a slaughter machine, we have small and medium sized pluckers. We can also provide equipment for a large-scale slaughterhouse operation.

You can see pictures of the different options below

Why Choose Hightop® Broiler Cage

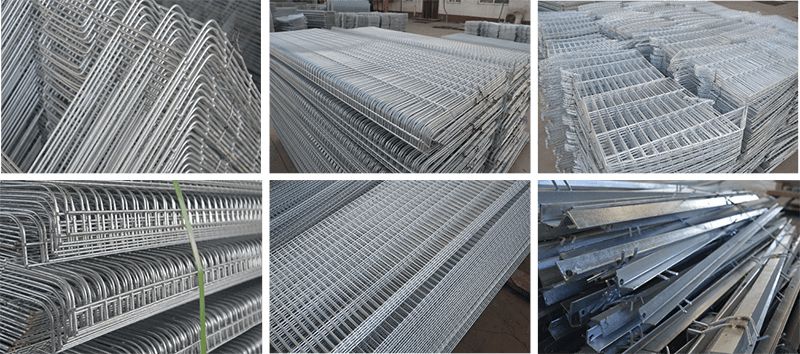

1. The better raw material selection

The hardness of metal wire depends on its carbon content. The metal wire we use for our broiler cage comes from a large steel factory in China and it is very tough and hard, as well as ductile and malleable so that it is not damaged under stress. Our broiler cage generally has a lifespan that is at least three years more than the common factory-made types.

2. Lifespan of up to 20 years

The thick zinc coating on the hot-dipped galvanized cage mesh will ensure your broiler cage will be protected from corrosion and rust for at least 10 years, while the broiler cage itself will last for double this time.

3. Broiler cage mesh design

The big sliding door design makes it easy to remove the chickens.

4. All necessary accessories are included

Accessories comprise a regulator or water tank, a water tank frame, a nipple drinker, installation tool, M-nail, water pipe, connector for the pipe, feeder connector, end cup, and the best type of PVC feeder trough.

5. Very easy to install.

We can send the installation video to you. You can check it out on YouTube: https://www.youtube.com/watch?v=htrRyqfKb6s

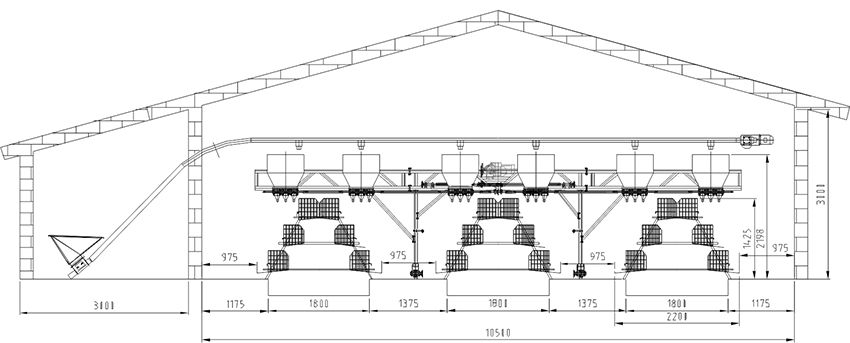

6. Free layout design

We offer a free design service based on the size of chicken house or coop you want.

- Broilers usually need six weeks to grow up, but you need to tell us at what age you want to sell your mature broilers. We also need to know how many broilers you want to feed every month, then we can estimate how many broiler cages you need.

- Our semi-automatic feeding machine is 0.55m wide. The minimum width to be able to use our semi-automatic feeding machine is 0.7 m, but if your area is very hot, and the scale of the chicken house is large, the width can be bigger to ensure good ventilation. Usually we design walkways to be between 0.7 m and 1.2 m.

- The 3-tier broiler cage is 1.75 m long, so the chicken house should be about 2.5m high. This is the most common type customers adapt, because 4-tiers tend to be a little high, more than 2m.

7. If LCL handles delivery, you will receive your goods in firm, solid packaging.

8. Many customers order full containers and get back to our company after they receive the goods.

We can also provide poultry house layout design