What is an Automatic Layer Pullet Cage

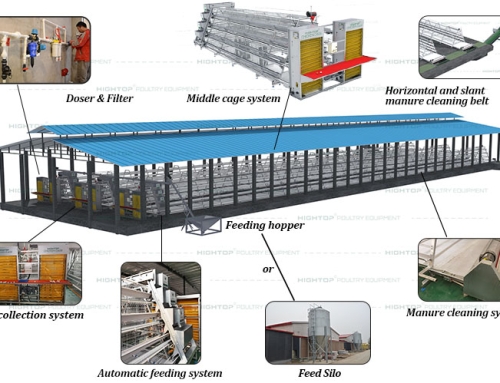

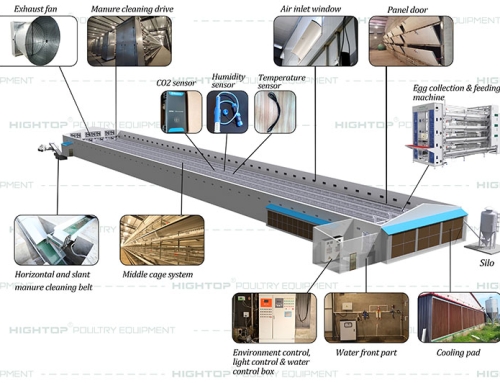

HIGHTOP Automatic Layer Pullet Cage is specially designed for raising chicks from 0 to 6 weeks old. This complete system includes a chick-friendly battery cage structure, mobile feeders, height-adjustable automatic drinkers, feeding troughs, water storage tank, brooder, lighting system, and manual manure removal device.

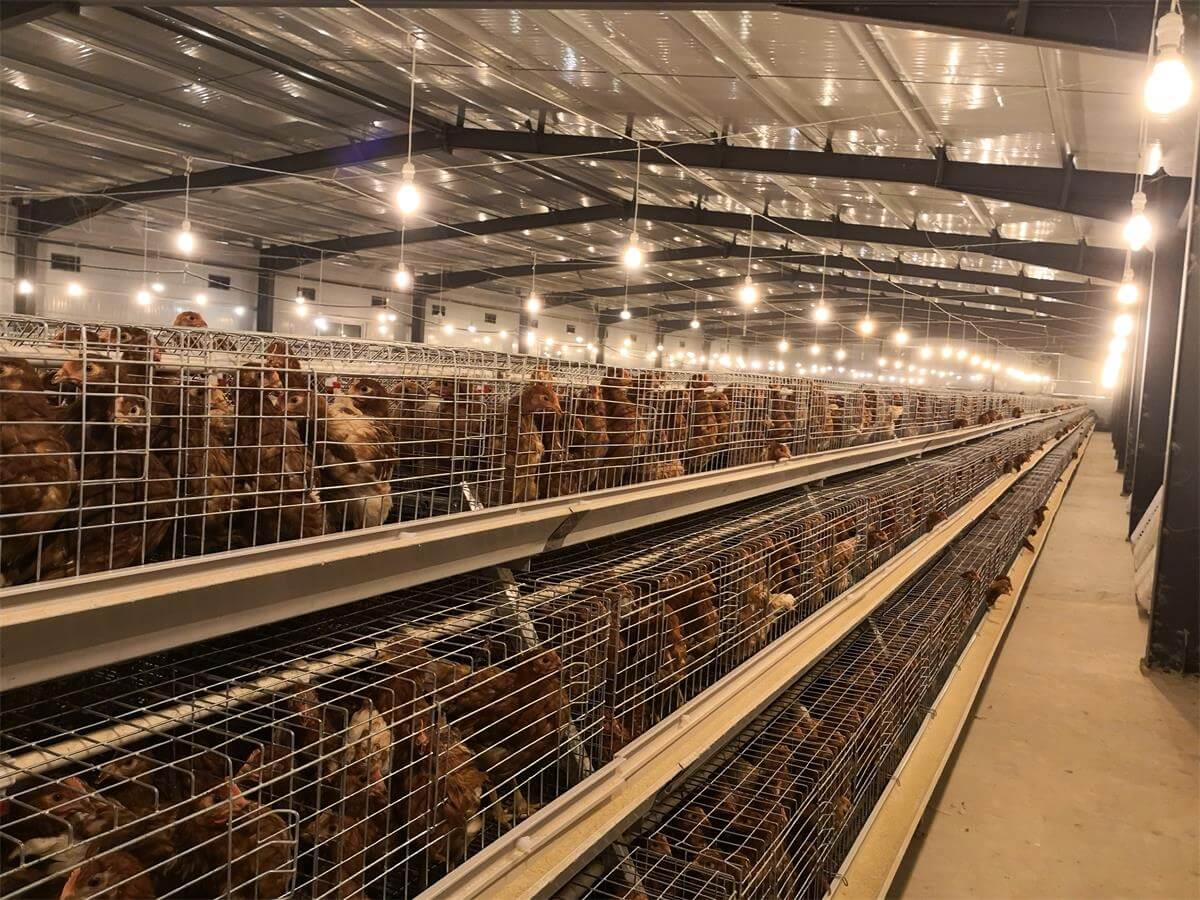

The Automatic Layer Pullet Cage helps poultry farmers increase breeding density and achieve centralized management, making large-scale chick farming easier and more efficient. By providing a clean, safe, and comfortable environment, the system greatly improves breeding efficiency and significantly raises the survival rate of chicks.

Leading Battery Cage System Manufacturer and Supplier

Hightop Poultry Equipment is a professional manufacturer and supplier of chicken battery cage systems from China. Our cage is made of high-quality mild steel, and its surface is heavy-duty galvanized or Galfan-coated, making it strong and durable. The service life is up to 30 years. Whether you own a medium or large chicken farm or even a small chicken house, we can supply a complete set of equipment for your poultry farm and provide corresponding solutions.

A Type Layer Brooder Cage Equipment Specification

| Specification of A Type Brooder Cage Equipment | |||||||||

| Cage size | Door No. /cage | Chicken No. /door | No. of layer | Capacity of one set of cage | Area per head (sqcm) | Length of the cage with frame | Width of installed cage with feeding machine | Height of installed cage with feeding machine | Length of manure cleaning machine |

| 1950*500*350 | 3 | 10 | 3 | 180 | 325 | 2000 | 2600 | 1900 | 1600 |

| 1950*500*350 | 3 | 10 | 4 | 240 | 325 | 2000 | 3100 | 2320 | 1600 |

Advantages of Raising Pullets with A Type Brooder Cage Equipment

Using A Type Brooder Cage Equipment offers significant advantages compared to flat rearing systems. The number of pullets raised per unit area can be increased by at least 50%, making it an ideal choice for maximizing farm capacity.

The design ensures that pullets and manure are completely separated — manure drops directly to the ground, which greatly reduces dust inside the chicken house and lowers the risk of diseases caused by contaminated feces. This directly results in a much lower mortality rate among pullets.

With the A Type Brooder Cage Equipment, pullet movement is minimized, reducing energy consumption and saving feed. The system also provides sufficient feeding and drinking positions, ensuring better uniformity and healthier pullets overall.

Farmers can easily observe the birds, identify clustering, and spot weaker chicks for timely care. At the same time, it eliminates the need for costly litter typically required in flat rearing systems.

The entire set of equipment is made from hot-dip galvanized steel, offering excellent corrosion resistance and ensuring a service life of 15-20 years.

Thanks to its intensive management design, the A Type Brooder Cage Equipment supports full automation — including automatic feeding, drinking, manure cleaning, and environmental control. This not only improves operational efficiency but also saves labor costs.

With its high-density rearing capability, this system helps save land and reduce investment costs. It is especially suitable for closed chicken houses, where automatic ventilation and temperature control ensure an optimal environment for pullet growth.

H Type Baby Chicks Cage System Specification

| Specifications of H Type Baby Chicks Cage System | |||||||||

| Cage size | Door No. /cage | Chicken No. /door | No. of layer | Capacity of one set of cage | Area per head (cm²) | Length of the cage with frame | Width of installed cage with feeding machine | Height of installed cage with feeding machine | Length of manure cleaning machine |

| 1950*350*500 | 3 | 10 | 3 | 180 | 227.5 | 2000 | 2600 | 1900 | 1600 |

| 1950*350*500 | 3 | 10 | 4 | 240 | 227.5 | 2000 | 3100 | 2320 | 1600 |

Advantages of H Type Baby Chicks Cage System

The H Type Baby Chicks Cage System offers outstanding advantages for modern poultry farming. It increases the number of chicks raised per unit area by 50% to 100%, helping farmers make full use of their space and investment.

The design makes it easy to observe chick growth, allowing for timely grouping and selection to promote uniform development. The feed trough is equipped with an adjustable partition, enabling accurate feeding for chicks at different growth stages.

The system features automatic timed manure cleaning, which greatly reduces the risk of disease transmission and lowers chick mortality rates. A water pressure regulator ensures balanced water supply at each nipple drinker, providing sufficient and even water for all chicks.

With a high level of automation, the H Type Baby Chicks Cage System integrates automatic feeding, drinking, manure removal, and cooling. This centralized management model not only improves breeding efficiency, but also saves energy and significantly reduces labor costs.

The entire cage system is made from hot-dip galvanized steel, offering excellent corrosion resistance and durability. With proper use, its service life can reach 15 to 20 years, making it a cost-effective choice for long-term farming operations.

By choosing H Type Baby Chicks Cage System, farmers can achieve intensive, efficient, and sustainable chick rearing, laying a solid foundation for future farm development.