Top 10 Types of Equipment for Layer Chicken Farming

If you are planning to start or expand your poultry farm, you will surely think about what kind of equipment is suitable regarding your quantity of chickens, building design, location, labor, and electricity, etc.

Here we list 10 of the most popular types of poultry equipment to use in a modern chicken farm.

1. Battery Chicken Cage

A chicken cage or a battery cage is widely used for commercial chicken farms because it saves space and feed. Moreover, the chickens are separated from the manure, so cage raising reduces the spread of disease and the risk of infection.

How to choose a good quality chicken cage?

In general, there are three factors that farmers consider when they choose a battery chicken cage: cage type, lifespan, and price.

1.1 Chicken Cage Type

Cage types are features of models, capacity, and cage sizes.

Two models are the H type battery layer cage and the A-type battery layer cage. These are commonly used for commercial or backyard chicken farms.

Chicken capacity is divided into 48, 96, 120, 128, and 160 birds per set. Both the 3 tier and 4 tier chicken cages are popular because their installation height is less than 2m, making it easier for staff to manage.

Cage sizes can be customized due to varying chickens’ weight and size in different countries. For example, our A45L layer cage (4 tier, 160 bird capacity) is more popular for the African market, while our A34 layer cage (3 tier, 96 bird capacity) is suitable for customers in the Philippines.

Having a suitable cage size is also essential for providing enough comfortable room so chickens can eat happily.

To sum up, the correct cage type should ensure that farmers can fully use land space and raise chickens at economical max capacity.

You can tell us how many chickens you have and the ideal chicken house dimensions, then we can custom make the best solution for you.

1.2 Chicken Cage Lifespan

“How long can I use this chicken cage?”

This may be the most common concern for a poultry farmer.

High-quality layer cages should feature good anti-corrosion resistance and have a strong structure, so farmers can use it for a long time.

The anti-corrosion quality of a cage is determined by its surface treatment, such as cold galvanizing, hot galvanizing, and PVC coating.

Cold galvanizing cages have an average lifespan of 7-10 years, PVC 10-15 years, and hot-dipped galvanized chicken cages last between 15-20 years.

However, the actual service life of a chicken cage depends on which environment they’re used in.

Cage strength is also a concern for most farmers. Sometimes, natural disasters strike, such as typhoons and earthquakes, which may destroy everything on the farm. It’s crucial to have chicken cages that can remain stable and solid.

To get a strong cage, Hightop chooses Q235 steel wire, which has higher tensile strength (780-820 MPa) and yield strength (235 MPa) than Q915 steel wire.

Moreover, our cage frame has anchors that can be mounted to the ground of the chicken house. This allows it to form an integrated structure with the concrete body. The chicken house won’t move or fall apart even under heavy wind or shock.

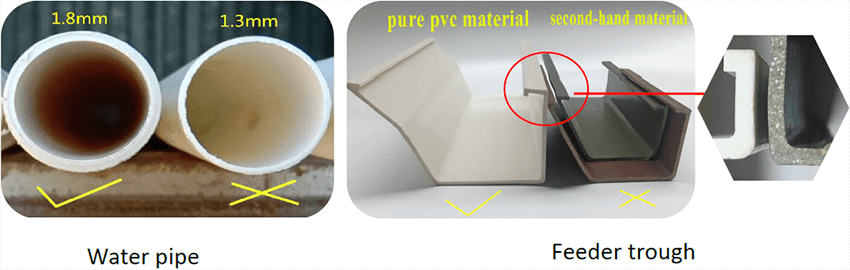

Last but not least, cage accessories are also an important factor that will determine the service life. A complete chicken cage includes the following accessories: feeder trough, water pipe, nipple drinker, water tank, cage frame, and installation tools. Opting to have high-quality chicken cage accessories can save you lots of time because you don’t need to change it often.

Below I will provide details on how to choose high-quality chicken cage accessories.

1.3 Chicken Cage Price

The cage price is determined by many factors: chicken cage types, surface treatment, accessories quality, and even the chicken cage layout.

Hightop Chicken Cage can always give you the best solution to help you cut costs because we have more than 16 years of experience in the industry.

If you have a budget, or you want to know the estimated cost to raise a certain amount of layer chickens, send us an email directly. We’ll provide you with a free quote within 24 hours.

2. Drinking Equipment

The nipple drinking system for the chicken cage is a closed water system. Farmers use water tanks, water regulators, water pipes, and nipple drinkers to make it a complete drinking system.

For saving water and preventing bacteria, a nipple drinker is the most ideal water supply equipment. You must choose a high-quality, leak-free drinker.

But how to make sure that you buy a good quality nipple drinker?

- First of all, the pins of the nipples must be made of stainless steel to prevent rust.

- Secondly, the rubber seal should be made of pure, non-toxic material, and it should also be thick enough to have a secure connection.

The nipple drinker with a drip cup is also available at Hightop.

3. Feeding Equipment

Firstly, a chicken feeder trough is used for cage raising. Choosing a suitable feeder trough size and shape is essential to conserve chicken feed. At the same time, pay attention to the feeder trough quality.

A good quality feeder trough should be made of pure PVC material because it is flexible and anti-corrosion resistant. Even someone weighing 80kg can stand on it, and it won’t crack.

A good quality feeder trough will look bright with no impurities in the cross-section. See the following picture:

Secondly, apart from the feeder trough, some feeding equipment may also be used, such as:

Semi-automatic feeding machine

This trolly uses rechargeable batteries, so it can be used even when there is no electricity, or you experience a power outage. You can feed 10,000 layer chickens in half an hour. All that is required is to put the feed into the hopper and select some buttons; then, it can start to turn and feed the chickens automatically.

This semi-automatic chicken feeder machine is designed according to chicken cage size (tiers and installation size). It can be used for layer chickens and broiler chickens.

Full automatic feeding machine

There are two types: gantry type and stepwise type. If the chicken quantity is less than 50,000 heads, then these two types are not recommended because they need enough electricity supply and are not cost-effective compared with semi-automatic types.

4. Manure Cleaning Equipment

Wet chicken manure leads to a high concentration of ammonia, which damages your hens’ respiratory system and eyes. Cleaning chicken manure regularly is good for your chicken’s growth and laying eggs.

A manure scraper machine can do this automatically. Before installing it, you need to build a manure channel. The channel size is determined by your chicken cage layout. You can leave a message here to ask for a FREE DESIGN from us.

After cleaning the chicken manure, don’t just throw it away. Dry manure can be sold directly. Fertilized manure can be used for plants or provide a source of biogas.

However, if you’re drying chicken manure naturally, this requires a considerable amount of time and causes a bad smell in the chicken coop. Well, now you can use a chicken manure dehydrating machine to get dry manure in no time.

This chicken manure dryer can handle about 17m³ of fresh manure per house and produces about 2 m³ dry manure per hour.

You just need to build a manure pit, which is used to store fresh manure and to separate the manure liquid. Then, a pump will suck and transfer fresh manure into the dehydrating machine.

With these two machines, you can turn your farm into a clean and green ecosystem.

5. Environment Control System

Chicken farm environment control includes two aspects: Ventilation & Temperature Control.

5.1 Ventilation:

Ventilating air removes excess heat, moisture, dust, and odors from the building and, at the same time, dilutes airborne disease organisms. No matter whether it’s an open type or closed type of poultry house, ventilation is essential.

As for open type chicken houses, elevated cage building is very popular, especially in the Philippines. The height of the shed is raised by 7-8 feet from the ground level using concrete pillars. This type of house provides sufficient ventilation & waste management.

Farmers typically use fans to give cooling and air exchange for chickens in such open type chicken houses.

For closed type chicken houses, also called tunnel vent systems, or CCS is a modern housing system that has become popular in recent years. No windows are designed, but big exhaust fans are fixed on one side, and cooling pads on the other side.

How many fans and cooling pads farmers need depends on the chicken density, age, and building dimensions.

5.2 Temperature control

Temperature control also includes two aspects: brooding heating and cooling.

5.2.1 Brooding heater

When chickens are of different ages, they require different room temperatures.

First of all, supplemental heat is needed in natural & powered ventilated houses to maintain desired indoor temperatures during cold weather & brooding.

The temperature required for chicks from 1 to 15 days is around 33-34 ° C in the first week, and then reduce it by 2 °C every week to the room temperature of about 20 °C.

Different brooding heating equipment includes infrared heating lights, gas type brooder heaters, electric brooder heaters, or diesel type brooder heaters. Each type is suitable depending on which energy source is cheaper or easier to get in your area.

5.2.2 Cooling

Secondly, when chickens are adults, or ready to lay, they may need lower room temperature than outside, especially in the summer season or in a tropical area.

Fogging or misting system

With a fogging system, water is sprayed through nozzles into the air, so that very small water droplets float around the house. As the fine droplets evaporate, they cool the entire room with minimal wetting of the ground floor.

There is a portable fogger machine, a hanging type fogger machine, and a ground-movable type fogger machine. Both particle size and spray range are adjustable.

Rotating fan systems with fogger nozzles are combined to achieve lower temperatures.

Ask your online consultant for more information.

Cooling pad system

For a closed type poultry house, a wet pad (cooling pad) is widely used.

Pads are made of corrugated cellulose, shredded fibers, and other materials. They provide cooling by having moisture in the pad evaporate as outside air flows through the pad into the house. The bird’s optimum temperature requirement is 24 ℃, and relative humidity is around 50 to 60%.

The typical cooling pad dimension is 600mm wide and 150mm thick. The pad height can be customized according to your chicken house dimensions.

Other accessories of cooling pad systems include a water pump, pipes, and filter.

6. Lighting

Ordinary bulbs are commonly used for lighting in most chicken farms, but there is a trend of using energy-saving lamps (LED bulbs).

Besides energy saving, another reason why LED lights are becoming more and more popular is that many tests report that LED lights can effectively promote chicken growth and reduce cannibalism in poultry.

LED lights simulate the sunrise to sunset cycle. Chickens adapt better behaviors under such natural light conditions. The chicken’s egg appetite, movements, feed intake, and egg production are improved by using LED lights.

Many chicken farms are equipped with switches that are automatically controlled by a timer that replaces manual switches to ensure accurate and reliable lighting time.

7. Disinfection Equipment

If you’ve been dealing with a chicken disease or illness, by all means, disinfect that coop! This is especially true if you are considering bringing in new birds or replacing your chickens.

Disinfectants can be made by using ULV fogger equipment. The types of disinfectants generally used are phenolic compounds, iodine or iodophors, chlorine compounds, quaternary ammonium compound, and oxidizing compounds.

8. Immunization Equipment

Immunization or vaccination equipment plays an important part in the health management of poultry flocks.

Day-of-age spray vaccination at the hatchery is widely accepted by most US poultry veterinarians. Choose our 2L type ULV fogger machine, which has eight nozzles, so you can adjust the particle size according to the chicken’s age.

For the vaccination of 18-day-old chicken embryos as an aid in the prevention of very virulent Marek’s Disease and Infectious Laryngotracheitis. A skilled worker can make vaccination for about 4500 chicks with our vaccination injection machine.

9. Incubator

A complete egg incubator includes both setter and hatcher. Temperature, humidity, and egg turning functions are all automatic. A good quality incubator can achieve more than a 95% hatching rate.

10. Debeaking

Removing the upper beak from a bird, especially layer hens, prevents egg eating or attacks to other birds. Using an automatic debeaker can help you do this fast and helps to maintain the health of your chickens.

Now, you have a general understanding of what kind of poultry equipment you may need for your layer chicken farm. You can decide what you need according to your chicken quantity, building design, and budget.

If you need any professional advice, email, or call us directly!

Leave A Comment